81

Cutter Compensation

96-8000 rev R June 2007

ENTRY AND E XIT FROM C UTTER C OMPENSATION

Cutting should not be performed when entering and exiting cutter compensation or when changing from left side to

right side compensation. When cutter compensation is turned on, the starting position of the move is the same as

the programmed position, but the ending position will be offset, to either the left or right of the programmed path, by

the amount entered in the, radius/diameter offset column. In the block that turns off cutter compensation, the

starting point is offset and the ending point is not offset. Similarly, when changing from left to right or right to left

side compensation, the starting point of the move needed to change cutter compensation direction will be offset to

one side of the programmed path and end at a point that is offset to the opposite side of the programmed path. The

result of all this is that the tool moves through a path that may not be the same as the intended path or direction. If

cutter compensation is turned on or off in a block without any X-Y move, there is no change made to cutter com-

pensation until the next X or Y move is encountered.

An offset selection of D0 will use zero as the offset value and have the same effect as not using cutter compensa-

tion. If a new D value is selected with cutter compensation active, the new value will take effect at the end of the

proceeding move. You cannot change the D value or change sides during a circular motion block (G02 or G03).

When turning on cutter compensation in a move that is followed by a second move at an angle of less than 90

degrees, there are two ways of computing the first motion these are: cutter compensation type A and type B

(Setting 43). The first, type A, moves the tool directly to the offset start point for the second cut. The second, type

B, is used to clear fixtures or clamps or in cases when part geometry demands it. The diagrams on the following

pages illustrate the differences between type A and type B for both Fanuc and Yasnac settings (Setting 58).

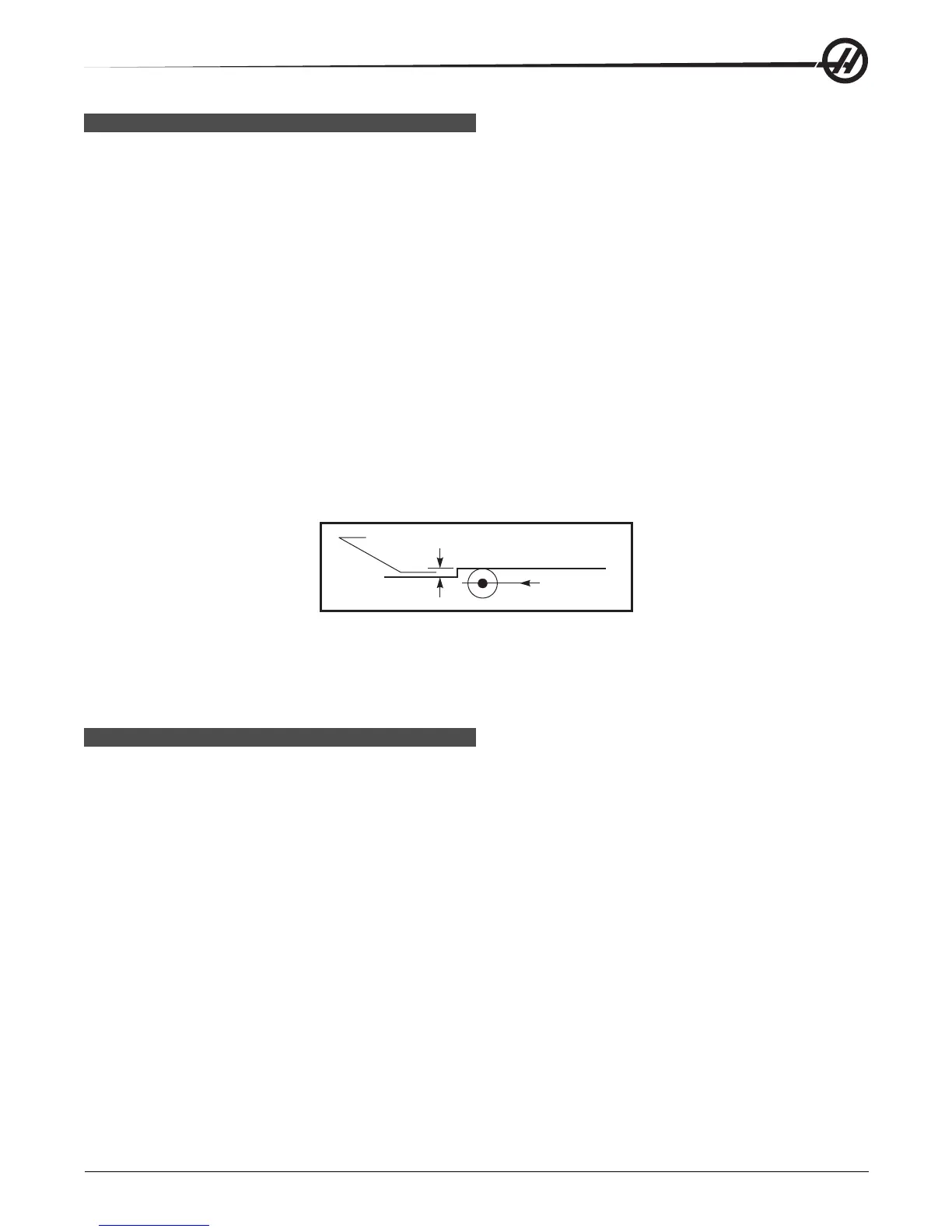

Move is less than cutter comp radius

Tool

Workpiece

Improper Cutter Compensation Application

Note that a small cut of less than tool radius and at a right angle to the previous motion will

only work with the Fanuc setting. A cutter compensation alarm will be generated if the machine is set to the

Yasnac setting.

FEED A DJUSTMENTS IN C UTTER C OMPENSATION

When using cutter compensation in circular moves, there is the possibility of speed adjustments to what has been

programmed. If the intended finish cut is on the inside of a circular motion, the tool should be slowed down to

ensure that the surface feed does not exceed what was intended. There are problems when the speed is slowed by

too much, therefore, setting 44 is used to limit the amount of feed adjustment. It can be set between 1% and

100%. If set to 100%, there will be no speed changes. If set to 1% the speed can be slowed to 1% of the pro-

grammed feed.

When the cut is on the outside of a circular motion, there is no speed-up adjustment made to the rate feed.

Loading...

Loading...