117

G Codes

96-8000 rev R June 2007

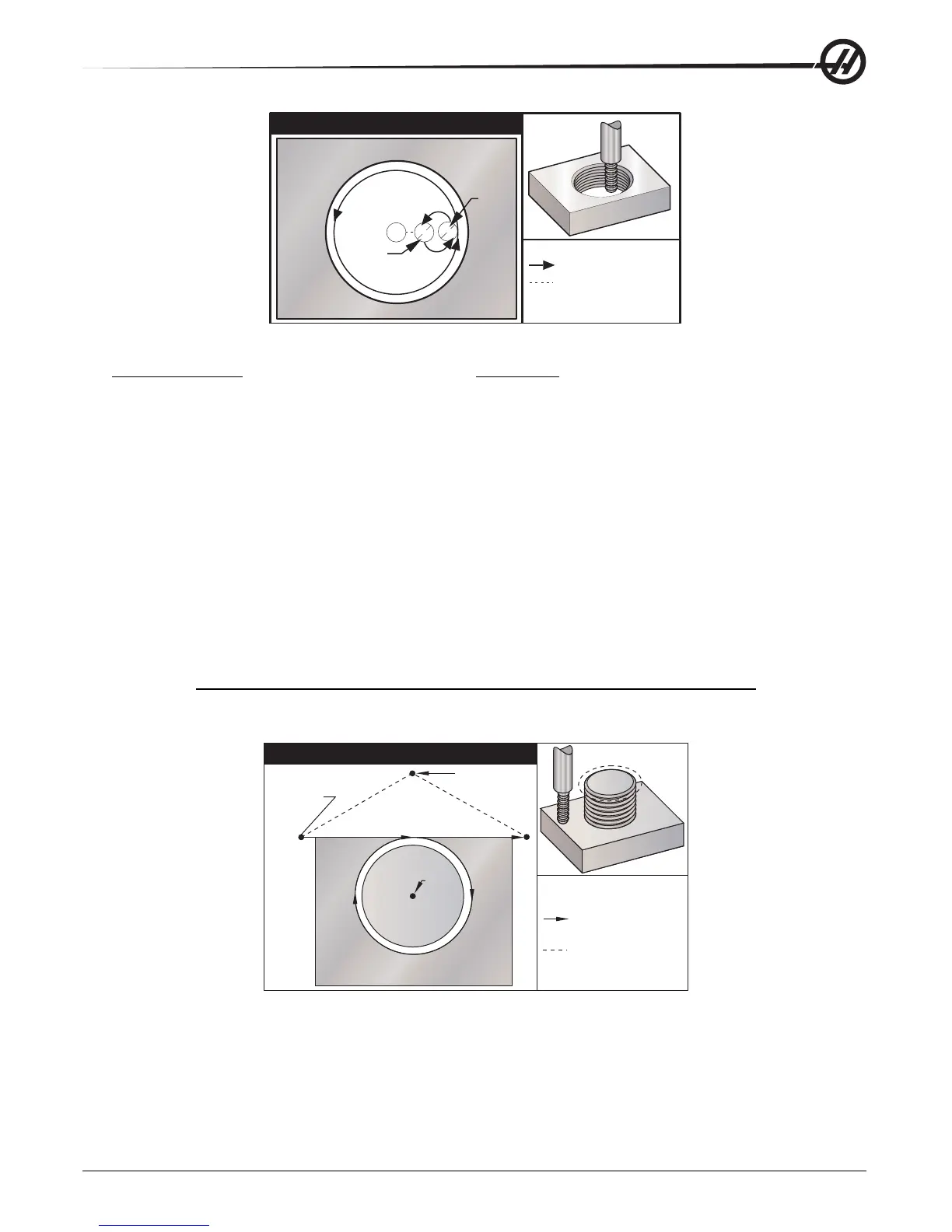

Thread Milling 1.5 dia. x 8 TPI

Tool Path

Turn On and Off

Cutter Compensation

I.D. Thread Milling Exercise

I.D. Thread Milling Exercise

Move away

from I.D.

Move to

I.D.

N5

N1

N4

N2

N3

Thread Milling Example

Program Example Description

%

O2300 (Thread milling 1.5 diameter x 8 TPI)

(X0, Y0 is at the center of the hole)

(Z0 is at the top of the part - Using .5 thick material

G00 G90 G54 X0 Y0 S400 M03

G43 H01 Z.1 M08

Z-.6

N1 G01 G41 D01 X.175 F25. (Turn on Cutter Comp)

N2 G03 X.375 R.100 F7. (Move to I.D. of bored hole)

N3 G03 I-.375 Z-.475 (One full revolution with Z moving up .125)

N4 G03 X.175 R.100 (Move away from the new threads)

N5 G01 G40 X0 Y0 (Cancel Cutter Comp)

G00 Z1.0 M09

G28 G91 Y0 Z0

M30

%

NOTE: Maximum cutter compensation adjustability is .175.

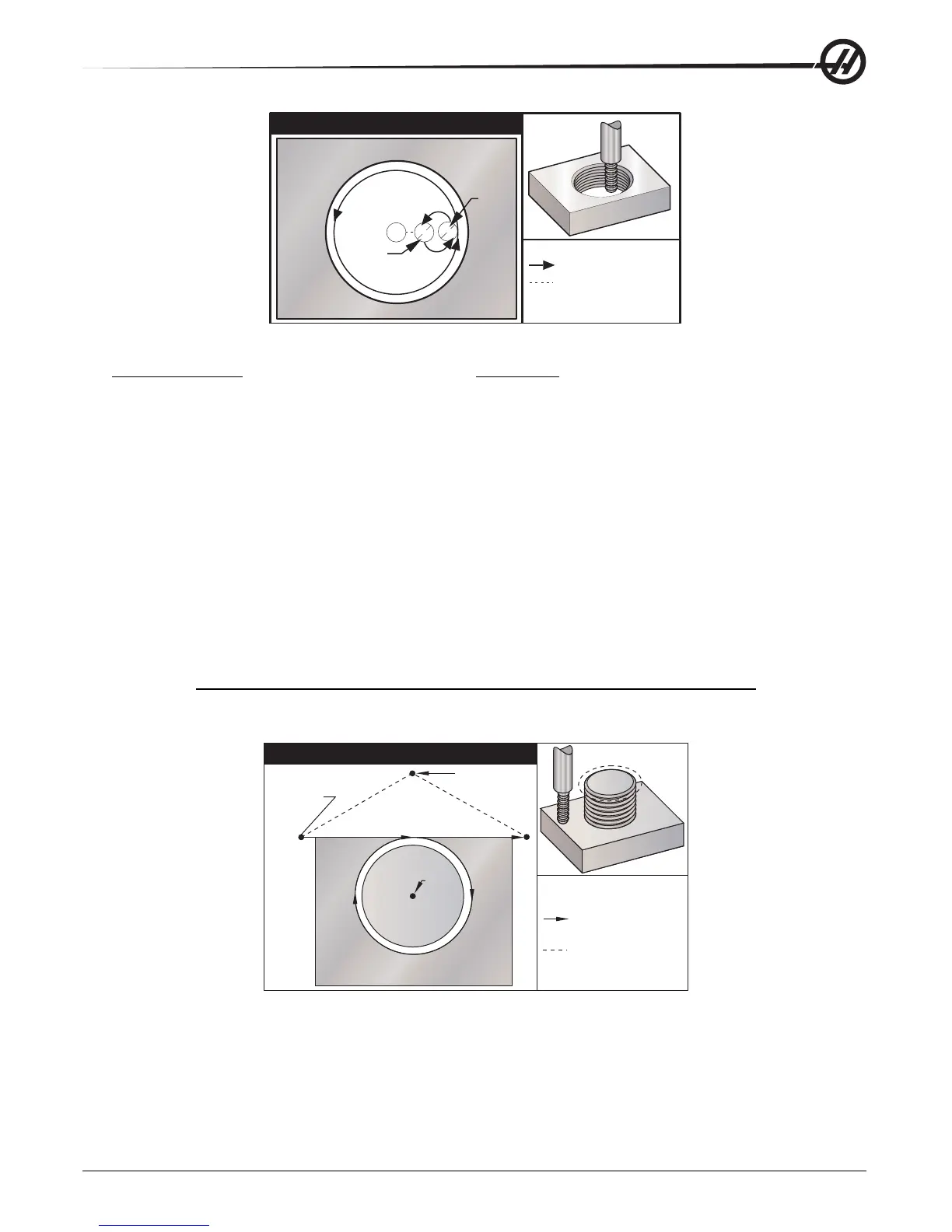

O.D. Thread Milling

2.0 dia. Material

XO, YO

Start Position

.250 Cutter

Thread Milling

2.0 dia. post x 16 TPI

Tool Path:

Rapid Positioning,

Turn ON and OFF

Cutter Compensation

O.D. Thread Milling Exercise

O.D. Thread Milling Example

Loading...

Loading...