129

G Codes

96-8000 rev R June 2007

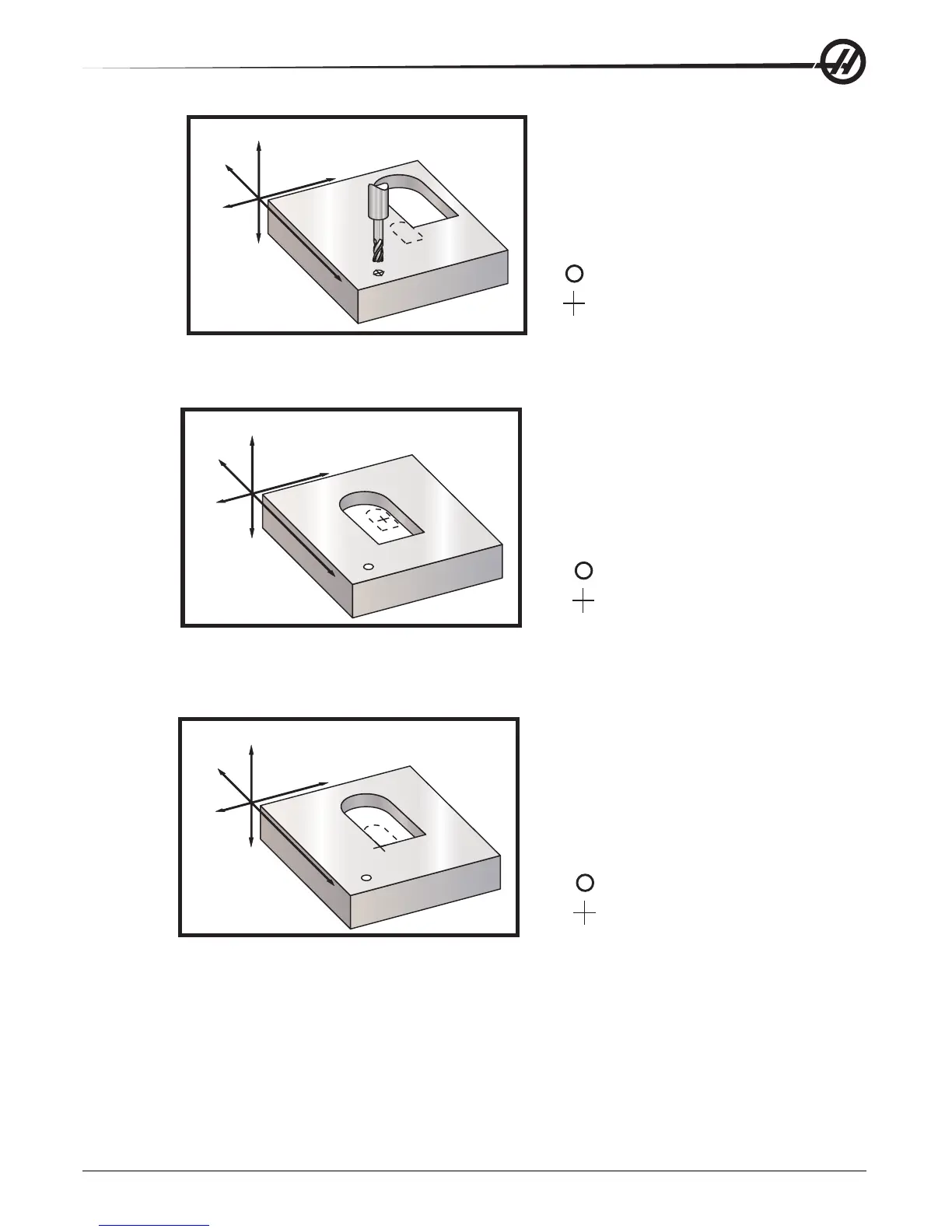

X

Z

Y

00010 ;

G59 ;

G00 G90 X0 Y0 Z0 ;

M98 P1 ;

M30 ;

= Work coordinate origin

= Center of scaling

G51 P2. (scaling center is X0 Y0 Z0) ;

00010 ;

G59

;

G00 G90 X0 Y0 Z0 ;

M98

P1 ;

M30 ;

=

Work coordinate origin

=

Center of scaling

G51

P2. (scaling center is X0 Y0 Z0) ;

G51 Scaling

The next example specifies the center of the window as the scaling center.

00011 ;

G59 ;

G00 G90 X0 Y0 Z0 ;

G51 X1.5 Y1.5 P2. ;

M98 P1 ;

M30 ;

= Work coordinate origin

= Center of scaling

00011 ;

G59 ;

G00

G90 X0 Y0 Z0 ;

G51

X1.5 Y1.5 P2. ;

M98

P1 ;

M30 ;

= Work coordinate origin

= Center of scaling

X

Z

Y

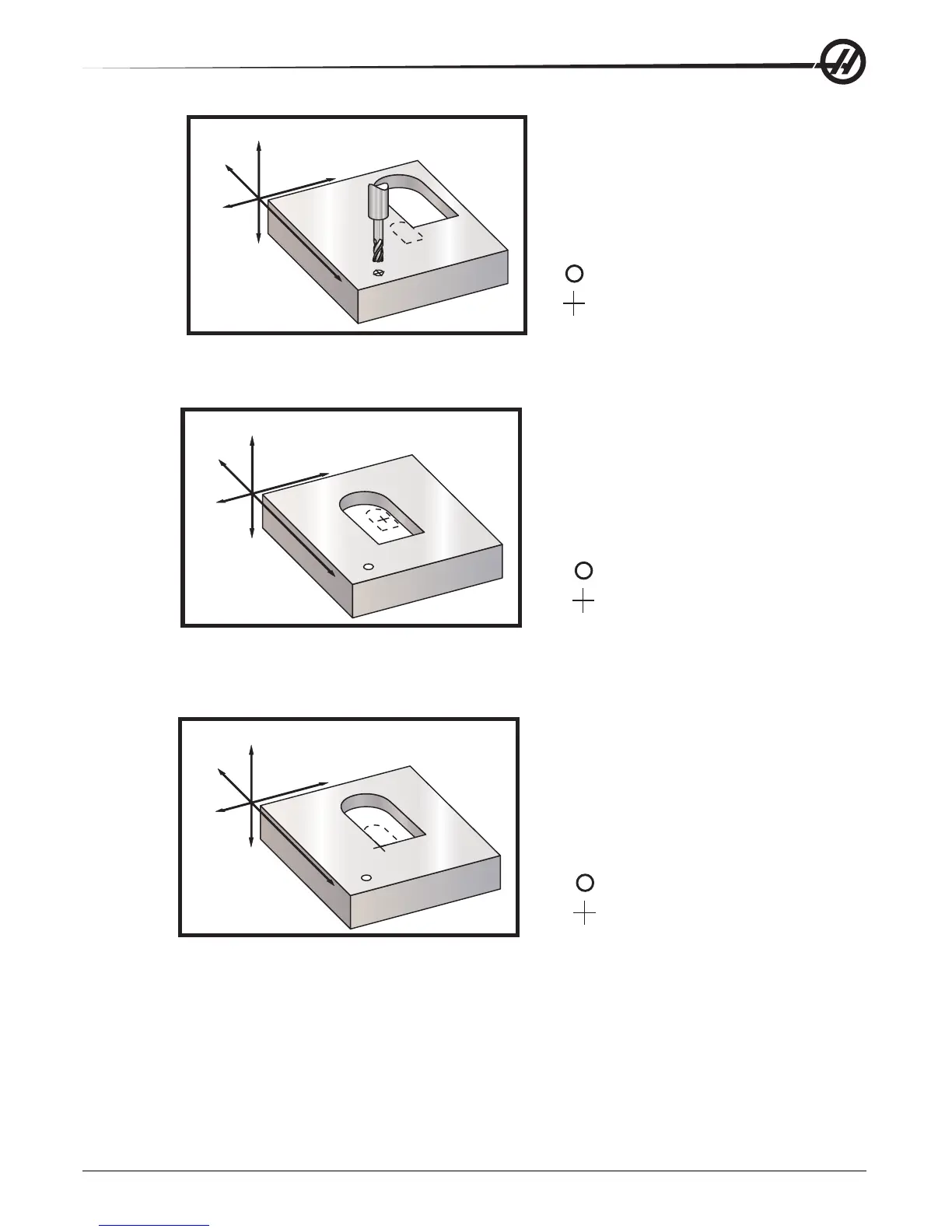

G51 Scaling

The last example illustrates how scaling can be placed at the edge of tool paths as if the part was being set

against locating pins.

00011 ;

G59 ;

G00 G90 X0 Y0 Z0 ;

G51 X1.0 Y1.0 P2 ;

M98 P1 ;

M30 ;

= Work coordinate origin

= Center of scaling

00011 ;

G59 ;

G00

G90 X0 Y0 Z0 ;

G51 X1.0 Y1.0 P2 ;

M98 P1 ;

M30 ;

=

Work coordinate origin

= Center of scaling

X

Z

Y

G51 Scaling

Programming notes:

Tool offsets and cutter compensation values are not affected by scaling.

Scaling does not affect canned cycle Z-axis movements such as clearance planes and incremental values.

The final results of scaling are rounded to the lowest fractional value of the variable being scaled.

Loading...

Loading...