Settings

178

96-8000 rev R June 2007

24 Leader To Punch

This setting is used to control the leader (the blank tape at the beginning of a program) sent to a paper tape punch

device connected to the first RS-232 port.

25 EOB Pattern

This setting controls the EOB (End of Block) pattern when data is sent and received to/from serial port 1 (RS-232).

This setting must match the transfer rate from the personal computer.

26 Serial Number

This is the serial number of your machine. It cannot be changed.

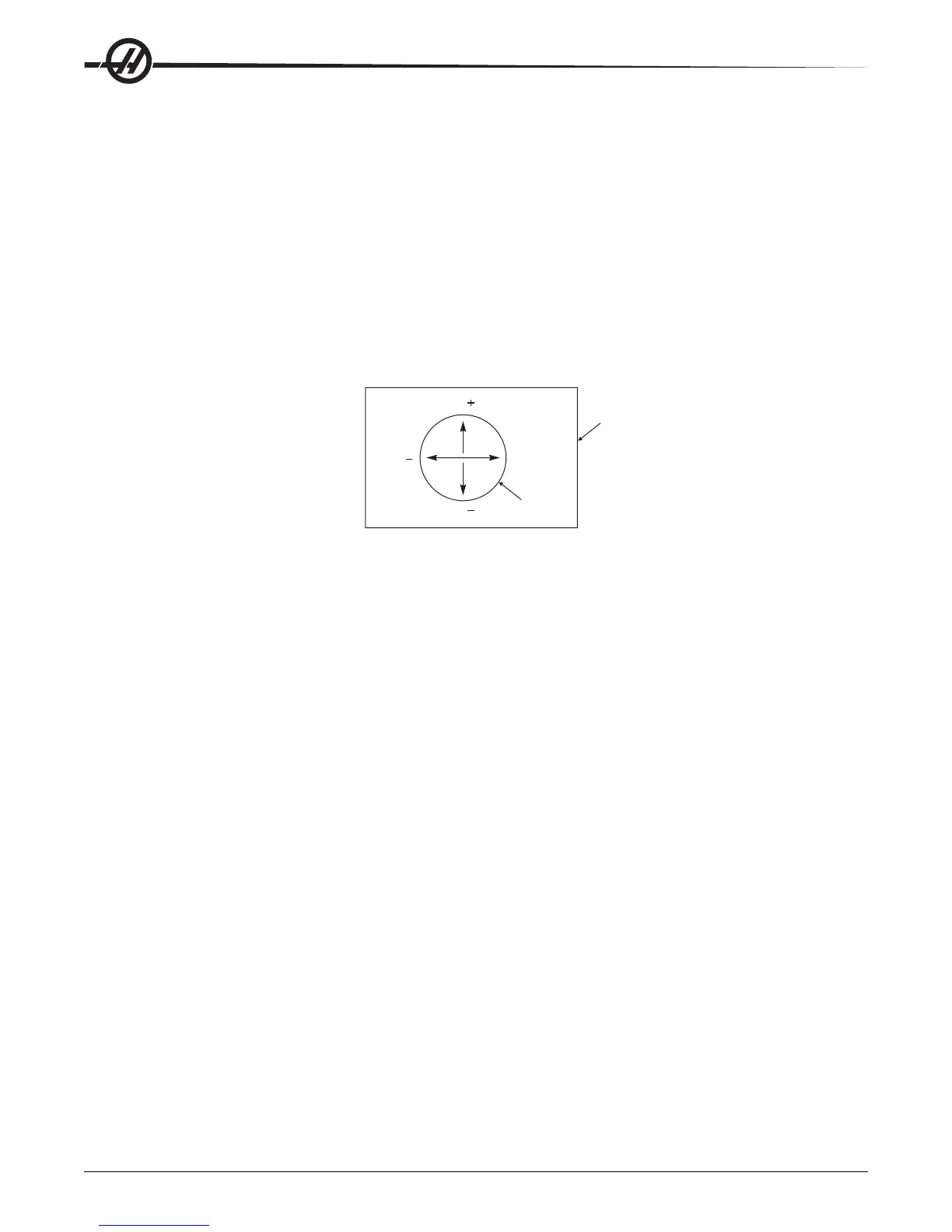

27 G76/G77 Shift Dir.

This setting controls the direction the tool is shifted (moved) to clear a boring tool during a G76 or G77 canned cycle.

Selections are: X+, X-, Y+, or Y-.

X

+

X

Y

Y

Bored Hole

Part

28 Can Cycle Act w/o X/Y

Turning this setting “ON” will cause the commanded canned cycle to complete without an X or Y command. The

preferred method of operation is with this setting ON.

When this setting is OFF, the control will stop if a canned cycle is programmed without an X or Y axis move.

29 G91 Non-modal

Turning this setting ON will use the G91 command only in the program block it is in (non-modal). When it is OFF,

and a G91 is commanded, the machine will use incremental moves for all axis positions.

30 4th Axis Enable

This setting initializes the control for a specific 4th axis. When this setting is OFF, the fourth axis is disabled; no

commands can be sent to that axis. See setting 78 for 5th axis. Note that there are two selections “USER1” and

“USER2” that can be used to set-up a unique rotary table.

31 Reset Program Pointer

When this setting is OFF, the Reset button will not change the position of the program pointer. When it is ON, the

Reset button will move the program pointer to the beginning of the program.

32 Coolant Override

This setting controls how the coolant pump operates. The “Normal” selection allows the operator to turn the pump on

and off manually or with M-codes. The “Off” selection will generate an alarm if an attempt is made to turn the coolant

on manually or from a program. The “Ignore” selection will ignore all programmed coolant commands, but the pump

can be turned on manually.

33 Coordinate System

This setting changes the way the Haas control recognizes the work offset system when a G52 or G92 is pro-

grammed. It can be set to FANUC, HAAS, or YASNAC.

Set to YASNAC

G52 becomes another work offset, just like using a G55.

Loading...

Loading...