181

Settings

96-8000 rev R June 2007

50 Aux Axis Sync

This changes the synchronization between sender and receiver for the second serial port. The second serial port is

used for auxiliary axes. The settings between the CNC control and the auxiliary axes must be the same.

Selecting “RTS/CTS” will tell the sender to temporarily stop sending data while the receiver catches up.

Selecting “XON/XOFF” uses ASCII character codes from the receiver to tell the sender to temporarily stop. XON/

XOFF is the most common setting.

The “DC CODES” selection is like XON/XOFF, with the exception that start/stop codes are sent.

The “XMODEM” selection is receiver-driven, which sends data in blocks of 128 bytes. XMODEM gives the RS-232

communication added reliability because each block is checked for integrity.

51 Door Hold Switch Override (Safety Switch Override)

Selecting “OFF” will not allow a program to start when the doors are open, and opening a door will cause the running

program to stop (the same as pressing Feed Hold).

Machines equipped with a hand held safety switch will go into feed hold if the safety switch is released.

When the control is powered on, this setting automatically returns to OFF.

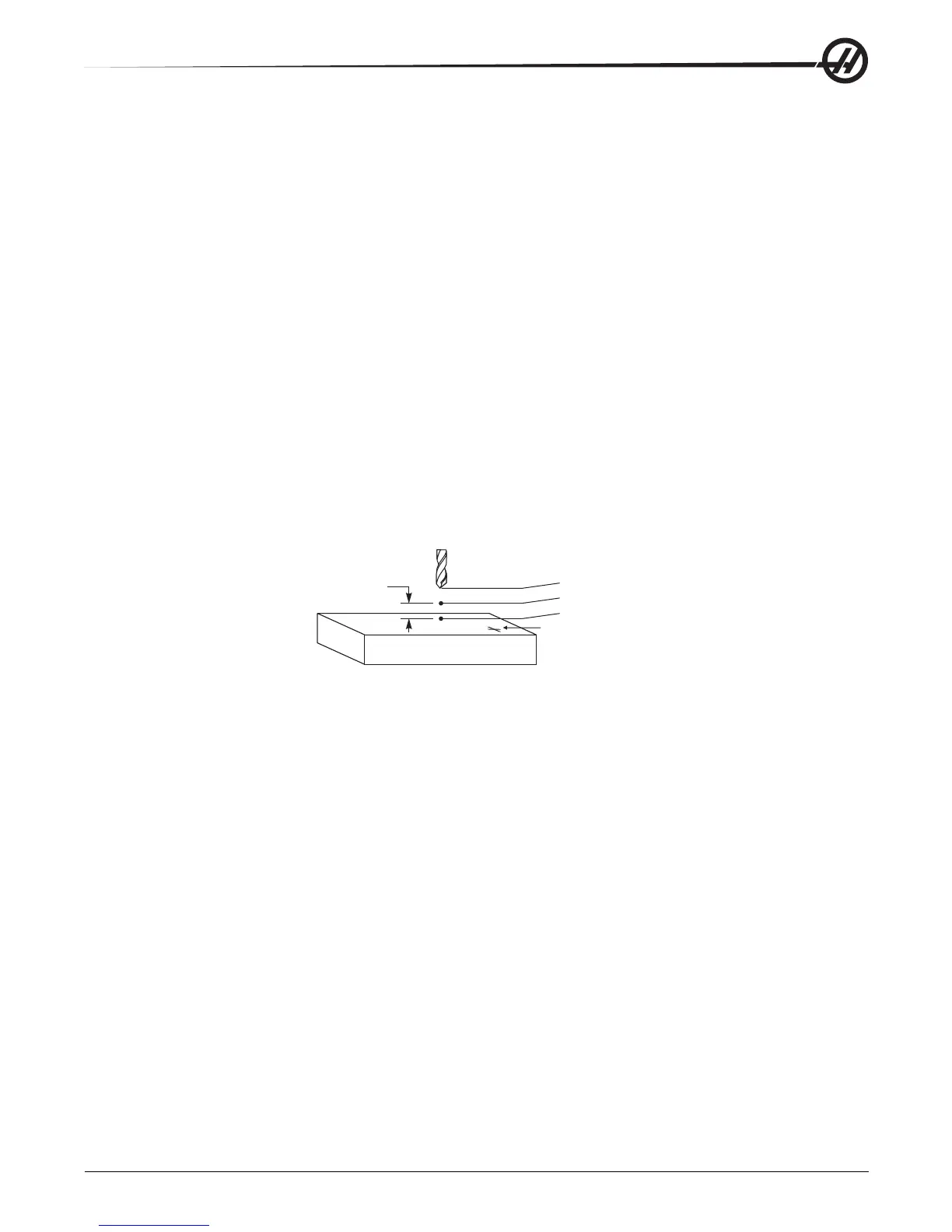

52 G83 Retract Above R

(Range 0.0 to 30.00 inches or 0-761mm). This setting changes the way G83 (peck drilling cycle) behaves. Most

programmers set the reference (R) plane well above the cut to ensure that the chip clearing motion actually allows

the chips to get out of the hole. However this wastes time as the machine will “drill” through this empty distance. If

Setting 52 is set to the distance required to clear chips, the R plane can be put much closer to the part being drilled.

Top of Part

Setting 52

Start Position

R Plane

New R Plane

53 Jog w/o Zero Return

Turning this setting ON allows the axes to be jogged without zero returning the machine (finding machine home).

This is a dangerous condition as the axis can be run into the mechanical stops and the possibly damage the

machine.

When the control is powered up, this setting automatically returns to OFF.

54 Aux Axis Baud Rate

This setting allows the operator to change the data rate for the second serial port (Auxiliary axis). This setting needs

to match the value in the auxiliary axis control.

55 Enable DNC From MDI

Turning this setting “ON” will make the DNC feature available. DNC is selected, in the control by pressing the MDI/

DNC button twice.

The DNC Direct Numeric Control feature is not available when set to “OFF”.

56 M30 Restore Default G

When this setting is ON, ending a program with M30 or pressing Reset will return all modal G codes to their defaults

and will also reset the Feed Per Rev back to its default.

57 Exact Stop Canned X-Y

The rapid XY motion associated with a canned cycle may not achieve an exact stop when this setting is OFF.

Turning this setting ON will ensure that the XY motion comes to an exact stop.

Loading...

Loading...