202

Maintenance

96-8000 rev R June 2007

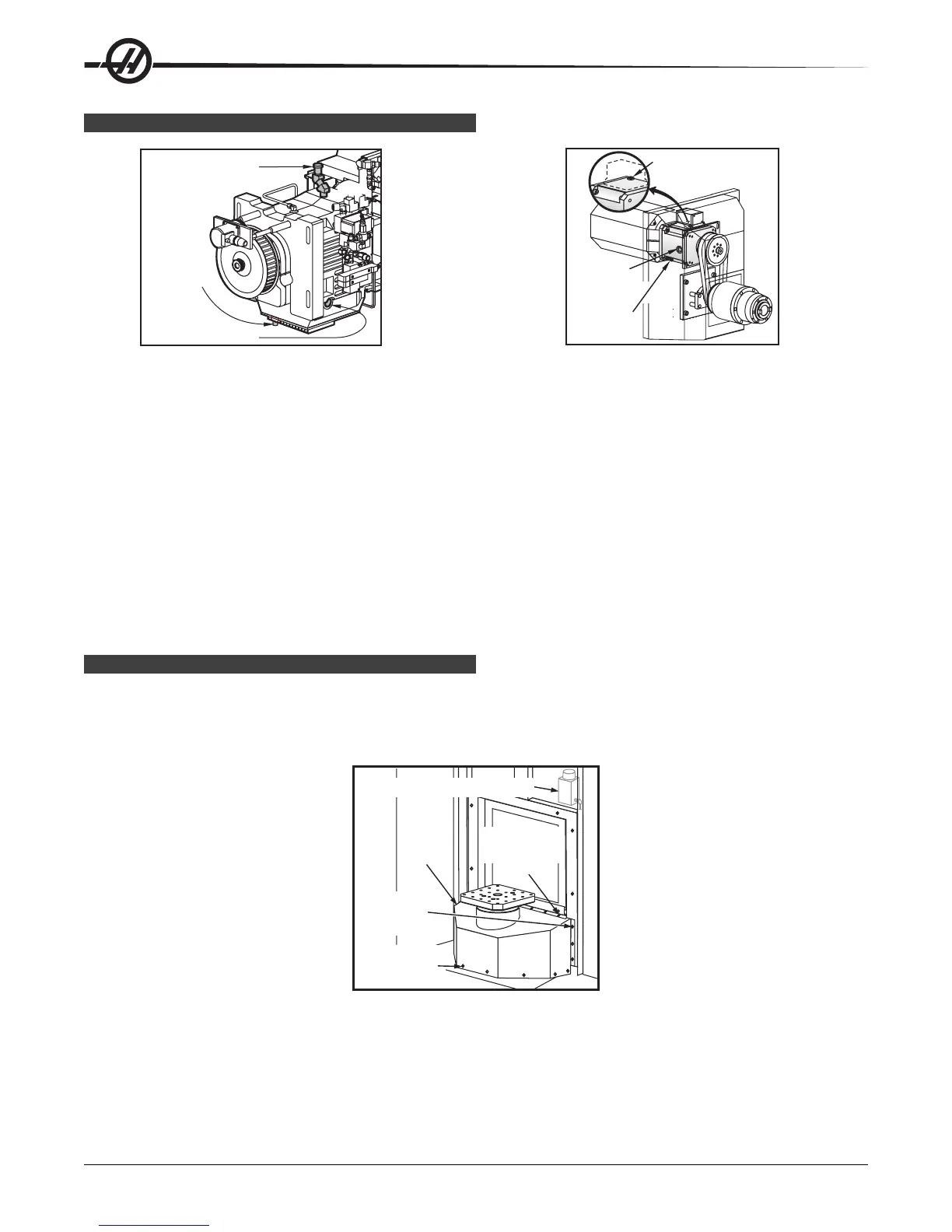

EC-1600 AND HS 3/4/6/7 TRANSMISSION O IL

Oil Fill

Oil

Drain

Oil Level View

Oil Fill Port

Oil Drain

Plug

Oil Sight

Glass

EC-1600 HS-3/4/6/7

Oil Check

Remove the sheet metal necessary to gain access to the transmission. View the sight glass on the side of the

transmission box as shown. The oil level should be half way on the sight glass. Fill as needed.

Oil Change

1. Remove the sheet metal from the spindle head.

2. Remove the drain plug as shown. Inspect the magnetic drainplug for signs of metal particles.

3. Blow downward with an air hose in the vicinity of the fill hole to prevent dirt and metal particles from

entering the gear case. Remove the fill plug.

4. Add Mobil DTE-25 gear oil until the oil level is half way up the sightglass.

5. Run a spindle warm-up and check for leaks.

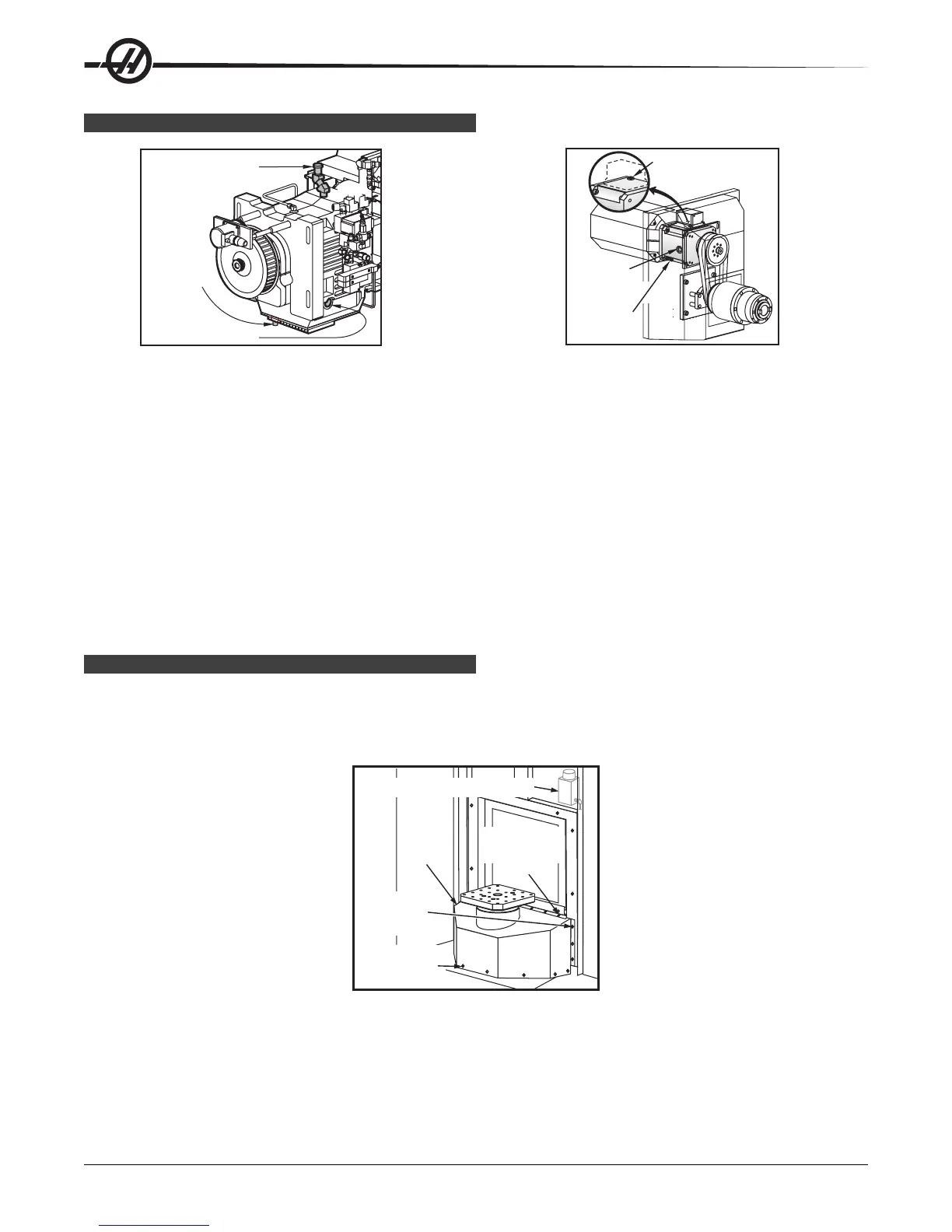

EC-SERIES P ALLET C HANGER R OTARY T ABLE

Oil Replacement

EC-300

Periodically check the oil level in the reservoir and keep it filled. It is not necessary to replace the oil.

Remove (8)

BHCS on

Bottom

Remove

(3) BHCS

on Sides

Clam

Shell

Rotary Table Oil Reservoir

Remove row

of (6) BHCS

on Top

EC-400 Full Fourth Axis Rotary Table (Perform Every 2 years)

Loading...

Loading...