Page 112

Periodic Maintenance

UVTOCMaintenance.fm

Section 7

7.3 Periodic Maintenance

The manufacturer is not responsible

for damage caused by the failure of

the user to follow the recommended

periodic maintenance.

Perform the following routine preventive maintenance on the recommended

schedule to ensure satisfactory long-term performance.

Important Note: The analyzer circuit board components are sensitive

to static electricity damage in a powered or unpowered state. Do not touch

circuit boards or their components without wearing a properly grounded

wrist strap. See Electrostatic Discharge (ESD) Considerations.

7.4 Shut Down

Important Note: The shutdown procedure must be strictly followed to avoid damage to

the analyzer on subsequent startup.

The analyzer should run continuously, if possible. Turning the lamps on and

off unnecessarily will shorten their life. If it is necessary to turn the lamps off,

observe the following cautions:

• Do not allow the UV lamps to remain lit without liquid flowing

through the reactor because plugging and/or damage to the reactor

may result.

• If measurement is not necessary or possible, substitute DI water for

sample in the analyzer.

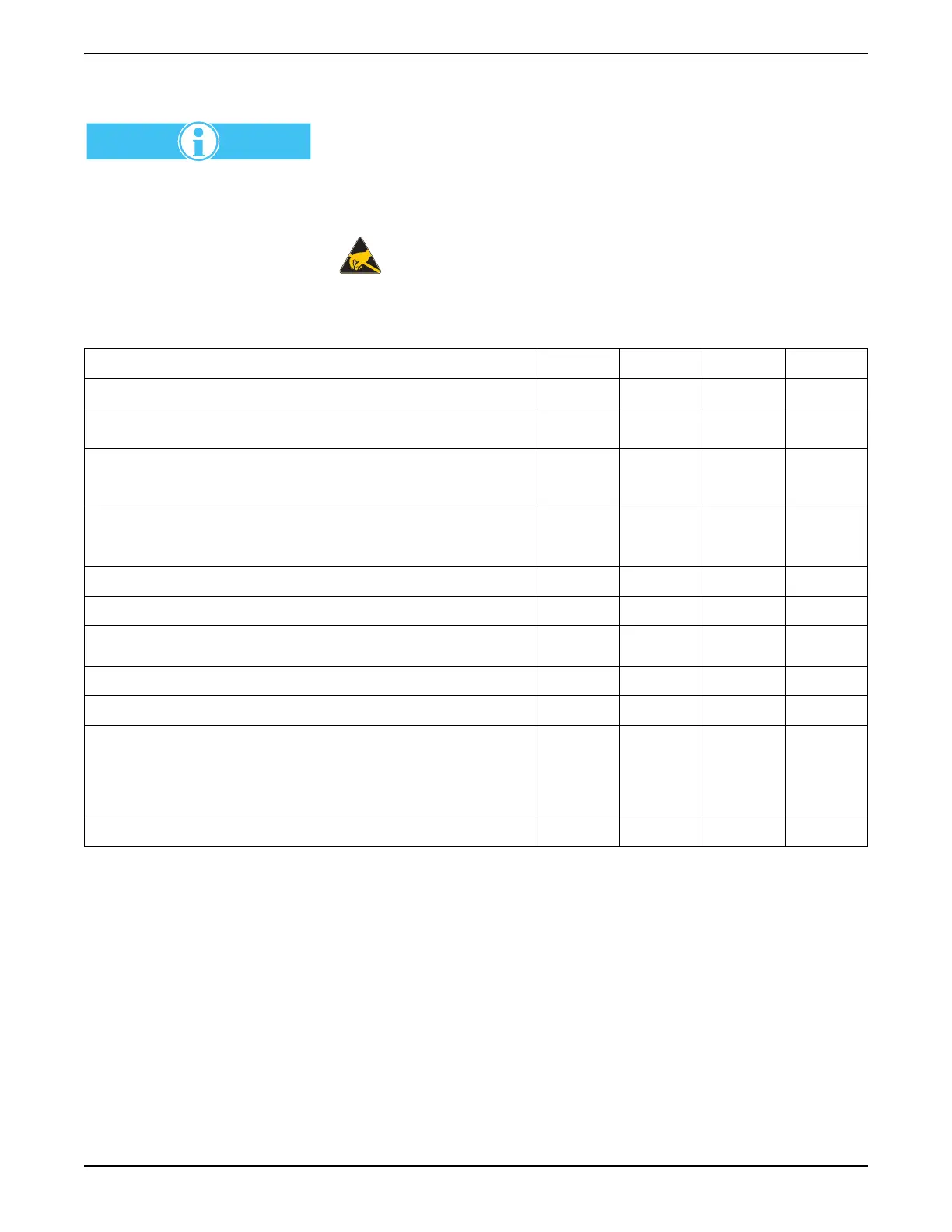

Table 14 Maintenance Tasks and Schedule

Maintenance Task Daily Monthly Quarterly Annually

Check for alarms. XXXX

Check for liquid leaks and other unusual conditions. Eliminate leaks

immediately to avoid analyzer damage.

XXXX

Check the flowmeter reading for the reactor carrier flow. It should be

stable and near the reading shown when the analyzer was

commissioned.

XXXX

Visually observe that the sparge gas bubbles are flowing correctly in

the GLS and sparger.

Note: The sparger on the TC version is bypassed with the conversion.

XXXX

Prepare reagents and refill containers. XXX

Recalibrate the analyzer, using fresh carbon standards. XXX

Check the pressure of the carrier gas feed to ensure that an adequate

supply is available.

XXX

If the analyzer is obviously dirty, perform a cleaning. XXX

Replace all peristaltic pump tubing. See Section 7.5. XX

Remove the UV lamps and remove the aluminum foil from the lamps to

perform lamp inspection. The lamp surface should be clear. If it is not,

run cleaning solution through the analyzer. Before returning to on-line

operation, wrap standard aluminum foil around each lamp to prevent

UV exposure.

X

Clean the IR sample cell and windows with a suitable solvent. X

Loading...

Loading...