Communication with a control system

102 A0293_06_E00_03 HBM: public MP85A

While not all measured curve data has been saved to the PC, the files have the

extension .tmp. Once data transfer is complete, the files are renamed with the

extension C85 or D85. This ensures that downstream software can reliably

detect the backup status and only accesses the process data when backup is

complete.

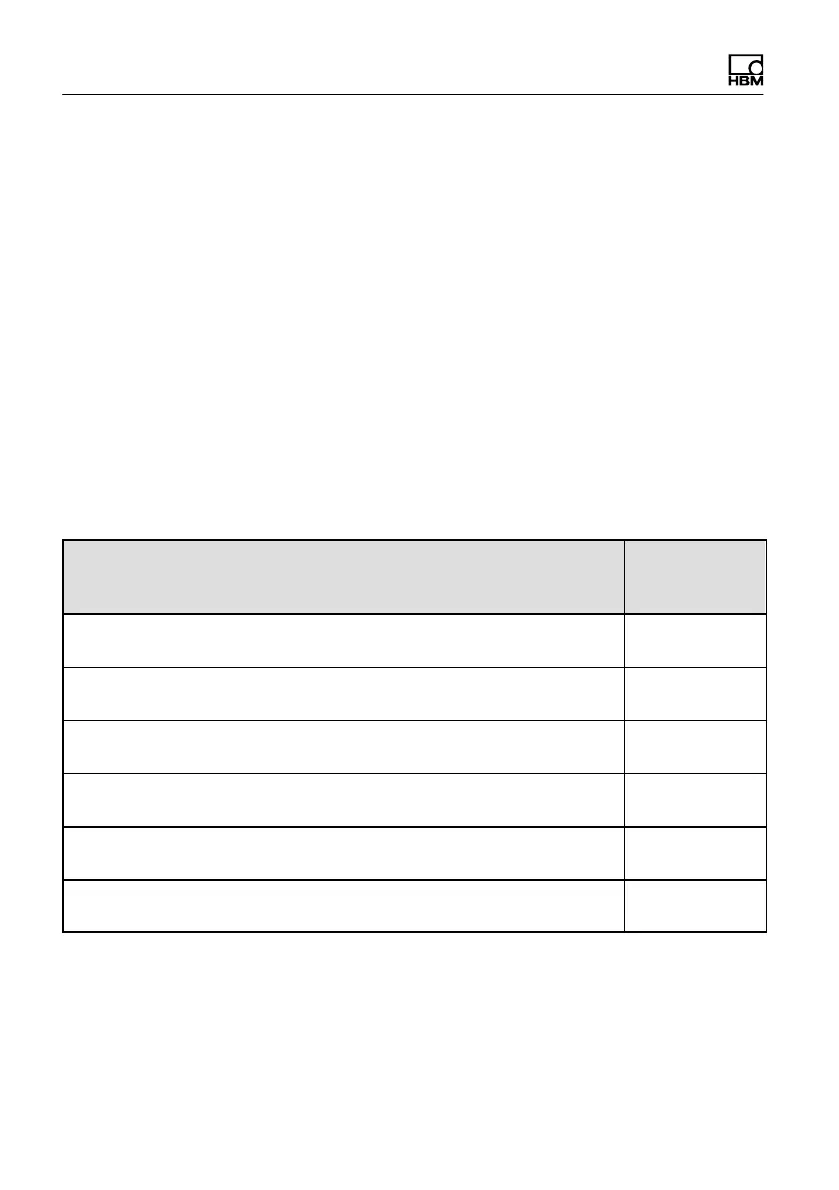

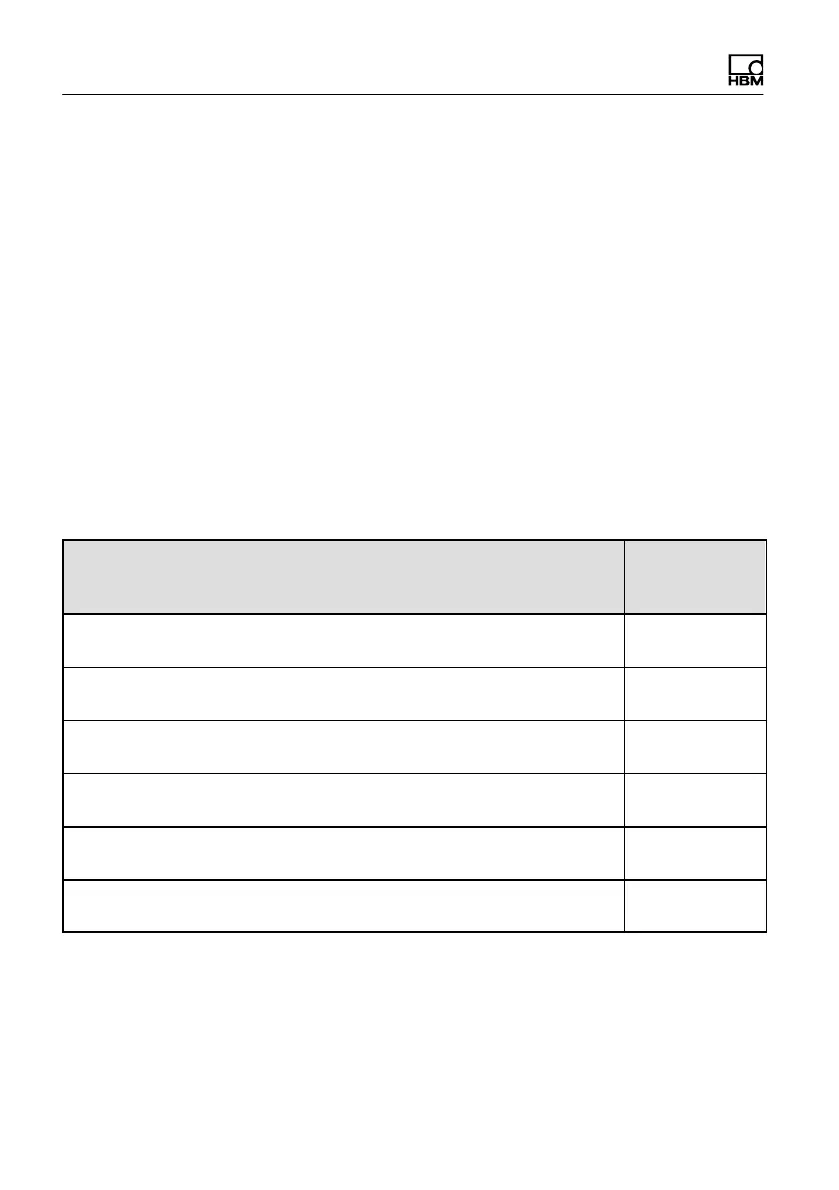

Typical process times during ongoing production in combination with

PLC machine control

The table below shows the approximate times required if the MP85A process

controller is exchanging cyclical data with a PLC via PROFIBUS, saving data

to an MMC/SD card or transferring it via Ethernet. The INDUSTRYmonitor soft

ware is running on the PC. The values that are actually achieved depend on

which hardware is used (PC), the network components (switch), and the net

work load. Times can vary widely from one process to another with Ethernet in

particular, due to the latency time.

Configuration (cyclical data was also exchanged via

PROFIBUS)

Time require

ment in s

(approx.)

1 x MP85A process controller, 500 measurement points, save

curves and results on MMC/SD card

2

3 x MP85A process controller, 600 measurement points, save

curves and results on MMC/SD card

2

1 x MP85A process controller, 500 measurement points, output

curves and results via Ethernet, Ethernet connected directly

4 / 5

3 x MP85A process controllers, 500 measurement points, output

curves and results via Ethernet, Ethernet connected via switch

4 / 5

3 x MP85A process controllers, 600 measurement points, output

curves and results via Ethernet, Ethernet connected via switch

4 / 6

3 x MP85A process controllers, 600 measurement points, output

curves only via Ethernet, Ethernet connected via switch

2 – 3

Loading...

Loading...