OperatiOn

4-18 HPR400XD Auto Gas – 806160

10

0

20

40

30

4

0

2

3

1

80

60

70

50

90

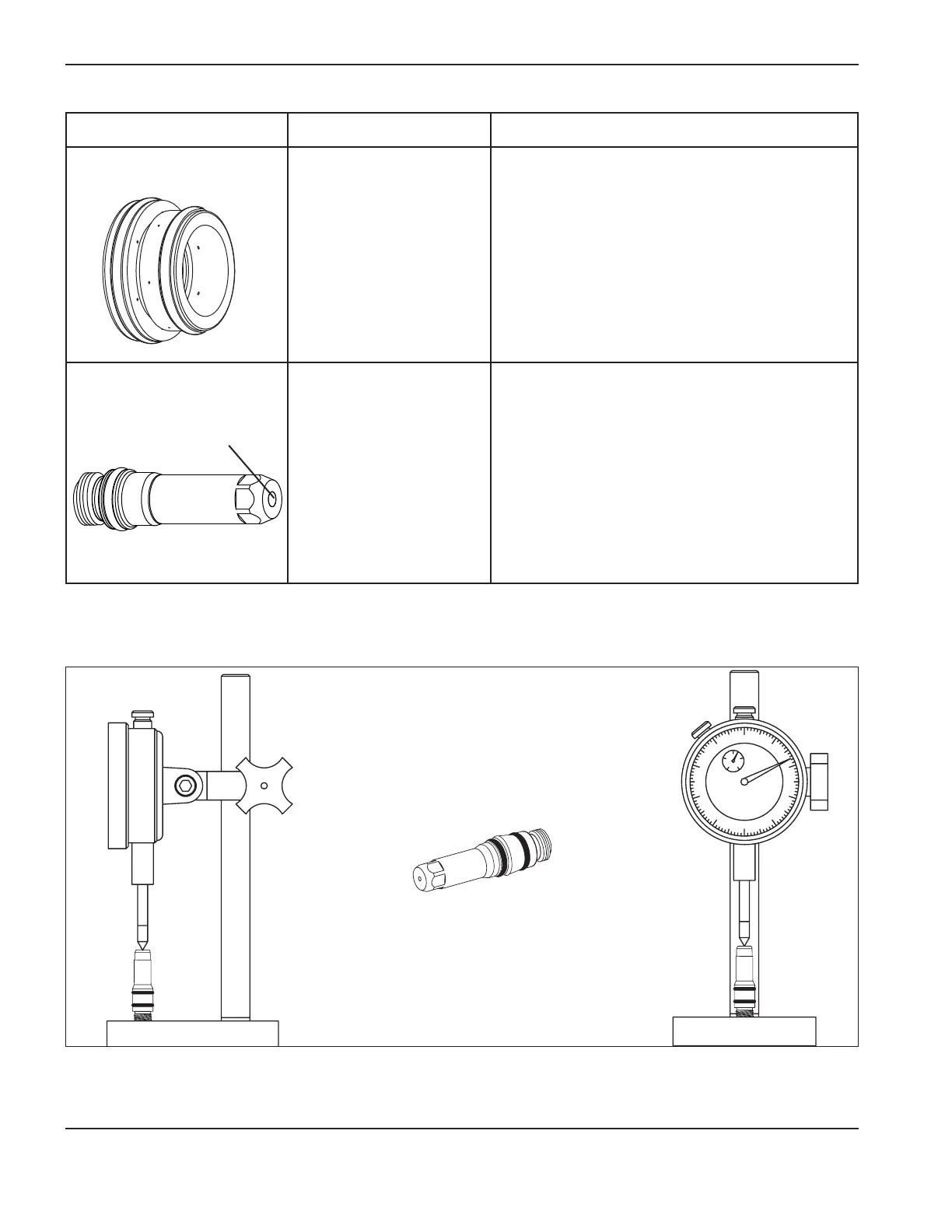

Electrode pit depth gage (004147)

Inspect Look for Action

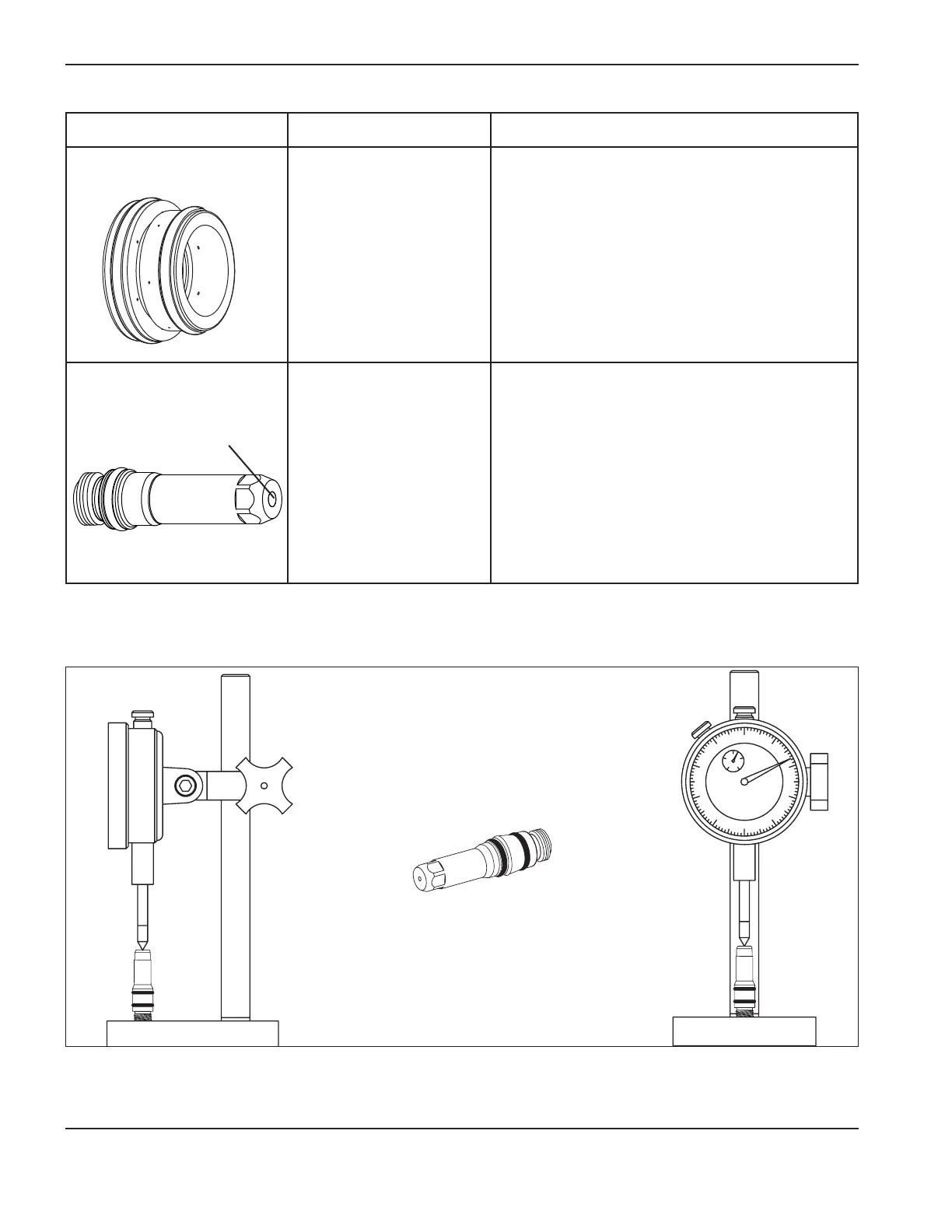

Swirl ring

General:

Chips or cracks

Blocked gas holes

Dirt or debris

O-rings:

Damage

Lubricant

Replace swirl ring

Replace swirl ring

Clean and check for damage; replace when damaged

Replace swirl ring

Apply a thin film of silicone lubricant if the o-rings

are dry

Electrode

Always replace the nozzle and

electrode as a set.

Center surface:

Emitter wear – a pit forms as

the emitter wears.

O-rings:

Damage

Lubricant

In general, replace the electrode when the pit depth is

1 mm (0.04 in.) or greater. For the 400 amp mild steel

electrode and all SilverPlus electrodes, replace the

electrode when the pit depth is 1.5 mm (0.06 in.) or

greater. See Electrode pit depth gage below.

Replace electrode

Apply a thin film of silicone lubricant if the o-rings

are dry

Emitter

Loading...

Loading...