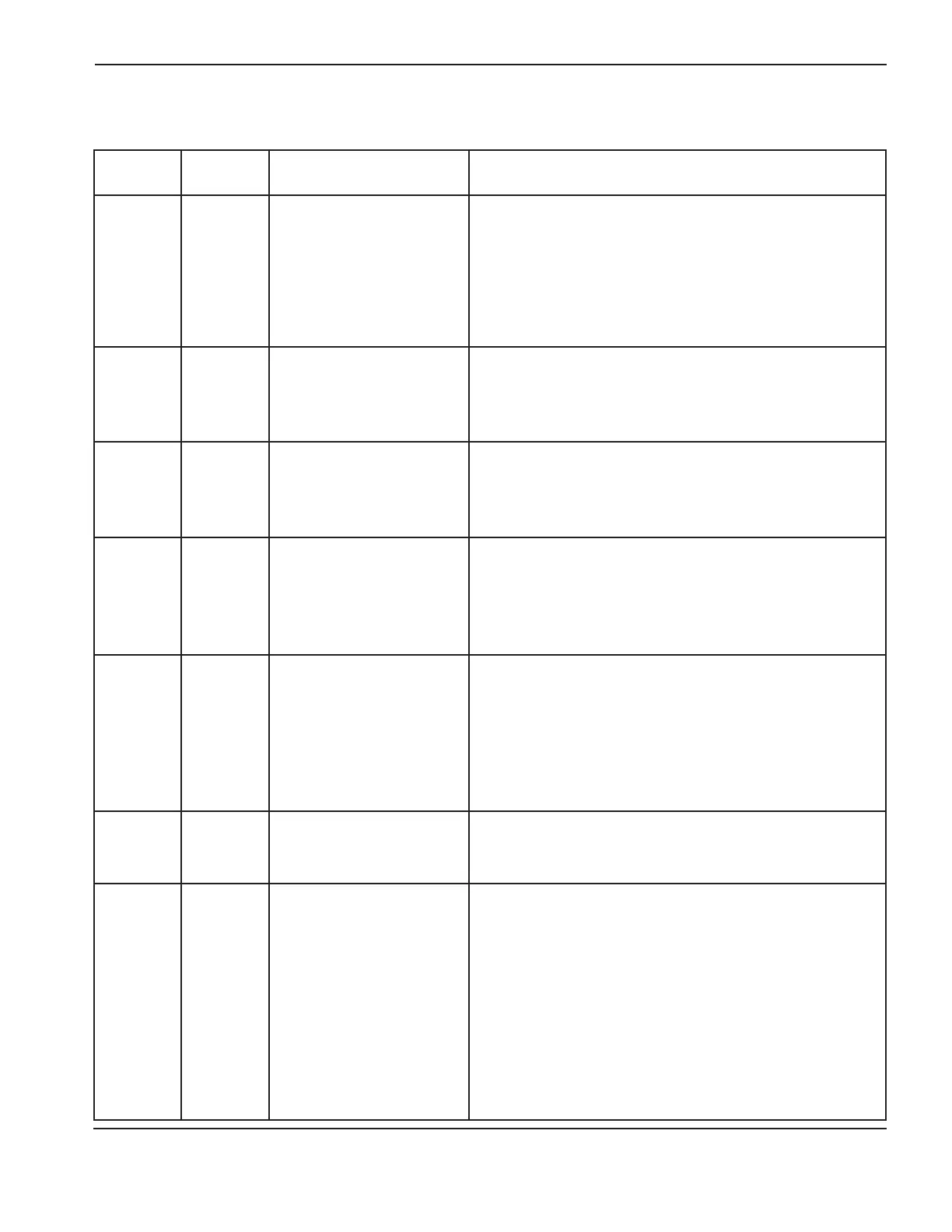

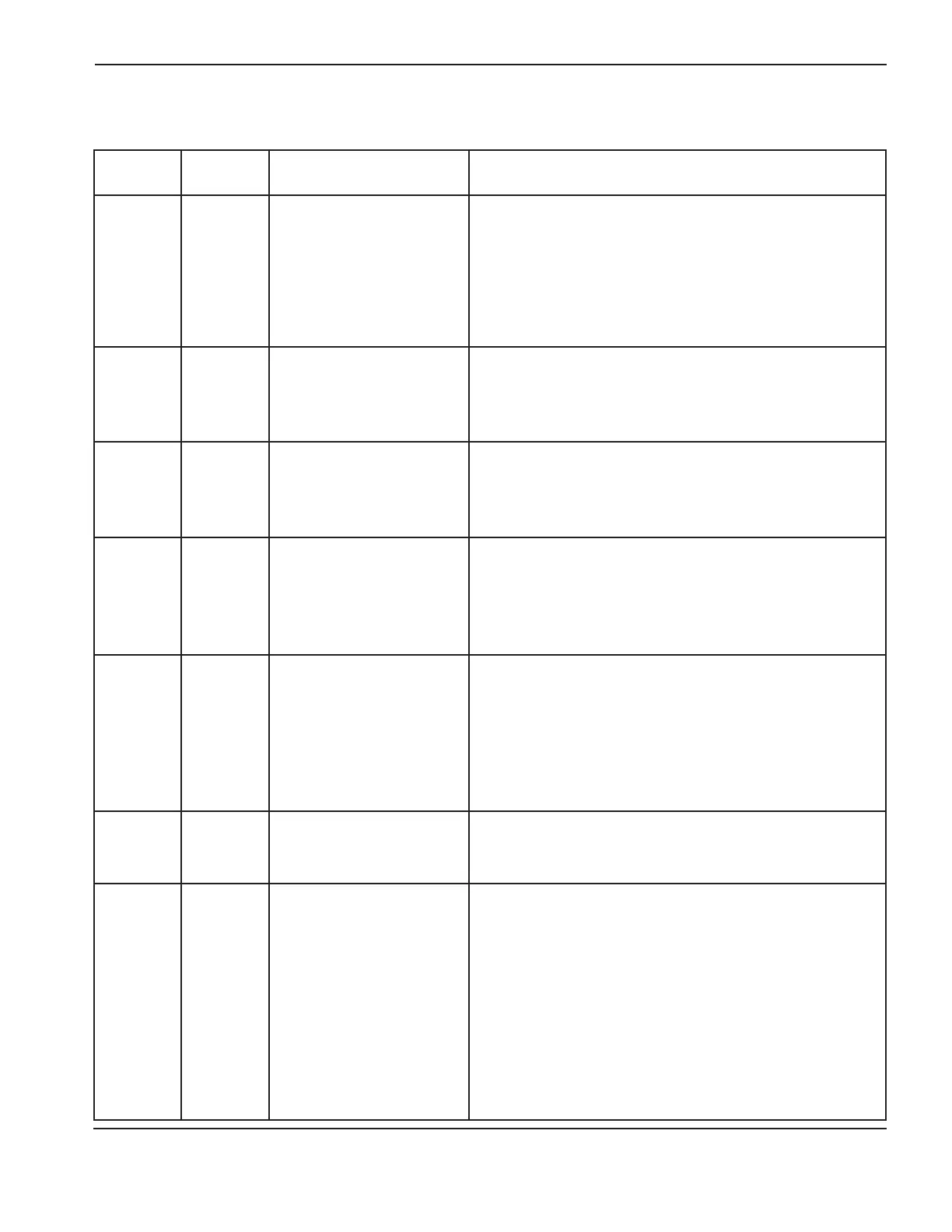

Maintenance

HPR400XD Auto Gas – 806160 5-15

Error code troubleshooting – error codes 054 to 061

Error code

number

Name Description Corrective action

054

High

shield gas

pressure

Shield gas pressure is over

upper limit of:

7.58 bar (110 psi) – manual

9.65 bar (140 psi) – auto

1. Verify gas supply regulator settings. See Setting the

supply regulators (Installation section).

2. Verify pressure settings on gas console with cut chart.

3. Solenoid at off-valve is not opening. Verify power to

valves, disconnect plasma and shield hoses exiting off-

valve. If pressures decrease, a valve is not functioning or

no power to the valve.

055

MV1 inlet

pressure

Auto Gas

Only

Motor valve 1 inlet pressure

is less than 3.45 bar

(50psi) or greater than

9.65 bar (140 psi).

1. Verify that gas pressure transducer P1 is between 3.45

bar (50 psi) and 9.65 bar (140 psi). Increase or decrease

the inlet gas pressure to correct the problem.

056

MV2 inlet

pressure

Auto Gas

Only

Motor valve 2 inlet pressure

is less than 3.45 bar

(50psi) or greater than

9.65 bar (140 psi).

1. Verify that gas pressure transducer P2 is between 3.45

bar (50 psi) and 9.65 bar (140 psi). Increase or decrease

the inlet gas pressure to correct the problem.

057

Cut gas 1

pressure

Auto Gas

Only

Cut gas 1 outlet pressure is

less than 3.45 bar

(50 psi) or greater than

9.65 bar (140 psi) in the

selection console.

1. Verify that gas pressure transducer P3 is between 3.45

bar (50 psi) and 9.65 bar (140 psi). Increase or decrease

the inlet gas pressure to correct the problem.

058

Cut gas 2

pressure

Auto Gas

Only

Cut gas 2 outlet pressure is

less than 3.45 bar

(50 psi) for non-mixing, or

less than 1.38 bar (20 psi)

when mixing or greater than

9.65 bar (140 psi) for non-

mixing and mixing.

1. Verify that gas pressure transducer P4 is between 3.45

bar (50 psi) and 9.65 bar (140 psi). Increase or decrease

the inlet gas pressure to correct the problem.

060

Low coolant

flow

Coolant flow is less than the

required 2.3 lpm

(0.6 gpm).

1. Verify that the correct consumables are properly installed.

2. Perform the coolant flow test procedure in the

Maintenance section of the manual.

061

No plasma

gas type

Manual gas - The gas

console control board is not

receiving signals from the

gas selector knob.

Auto gas - The selection

console is not receiving the

plasma gas type signal.

1. Auto gas - the process parameters may not have been

downloaded. Verify that the process information can be

viewed on the CNC screen.

2. Manual gas - the selector knob (2) may be set between

positions. Reset the knob.

3. Verify that there is power to the console by looking to

see if any LED on any board in the selection console

(auto) or gas console (manual) is illuminated. If no LED is

illuminated, verify that the fuse on the power distribution

PCB is in proper working condition.

4. If the problem still exists, replace the control board.

Loading...

Loading...