3 Installation and Wiring

-

43

-

3

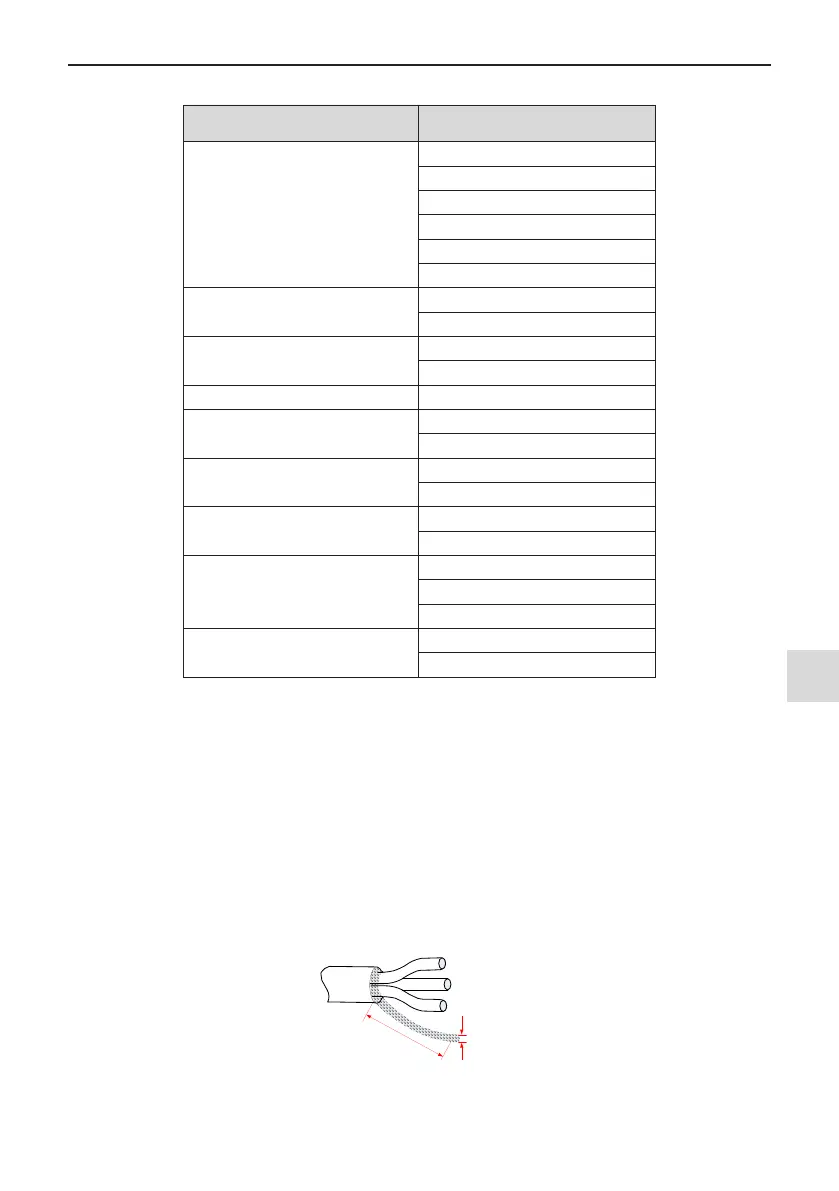

Table 3-5 Cable support bracket models

Cable Support Bracket Model Applicable AC Drive Model

MD500-AZJ-A2T1

MD500T0.4GB

MD500T0.7GB

MD500T1.1GB

MD500T1.5GB

MD500T2.2GB

MD500T3.0GB

MD500-AZJ-A2T2

MD500T3.7GB

MD500T5.5GB

MD500-AZJ-A2T3

MD500T7.5GB

MD500T11GB

MD500-AZJ-A2T4 MD500T15GB

MD500-AZJ-A2T5

MD500T18.5G(B)(-T)

MD500T22G(B)(-T)

MD500-AZJ-A2T6

MD500T30G(B)

MD500T37G(B)

MD500-AZJ-A2T7

MD500T45G(B)

MD500T55G(B)

MD500-AZJ-A2T8

MD500T75G(B)

MD500T90G

MD500T110G

MD500-AZJ-A2T9

MD500T132G

MD500T160G

●

Cable specication and installation of all cables connected to the drive output U, V, W must comply with

local safety regulations and relevant IEC standards.

●

Refer to Table 8-7 Peripherals and options for recommendations and copper conductor dimensions of ca-

bles in the main circuit.

●

To avoid risk of equipment damage or operating faults, do not connect a capacitor or surge absorber to the

output side of the AC drive.

●

Long motor cables can contribute to electrical resonance caused by distributed capacitance and induc-

tance. In some cases, this might cause equipment damage in the drive, in motor or in cables. To avoid

these problems, install an AC output reactor close to the drive if cable is longer than 100 m.

●

The shielding cables are recommended for the motor. The shielding layer must be wound onto the cable

support bracket. The drain wire must be grounded to the grounding (PE) terminal.

●

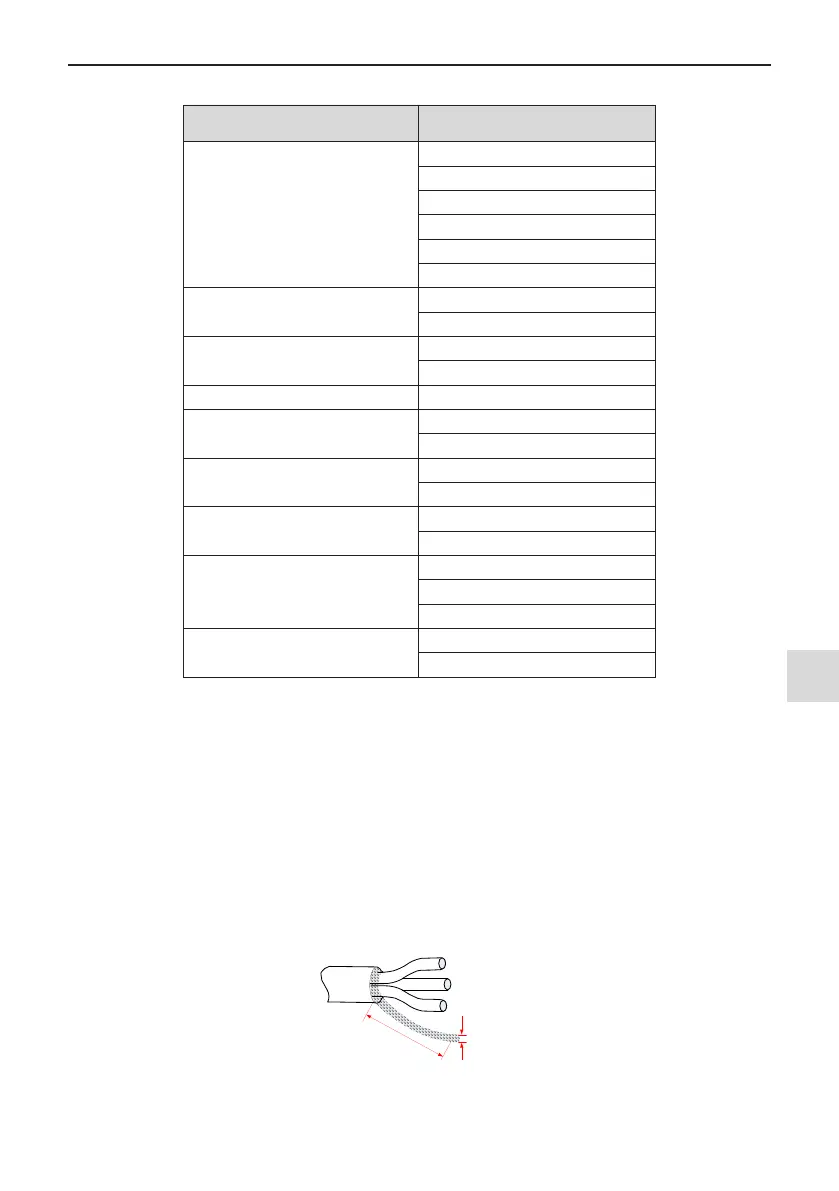

Ensure the drain wire of the motor cable shield is as short as possible and its width must be no less than

1/5 of its length.

Figure 3-35 Drain wire of motor cable shield

Loading...

Loading...