23

Intermec EasyCoder 201 II – Technical Manual

SETUP PARAMETERS, cont'd.

Feed Adjustment

The feed adjustment contains two parameters, Start adjustment

and Stop adjustment, that will be effected regardless of which

program is run. Such global adjustments can be further modified for

various purposes by the use of FORMFEED statements (see Intermec

Fingerprint Reference Manual) within the currently running pro-

gram.

Note: It is possible to turn off the label stop sensor or black mark

sensor for a certain amount of paper feed, and to override the start

adjustment and stop adjustment setup by means of the Intermec

Fingerprint statement LBLCOND, see the Intermec Fingerprint

Reference Manual. This feature is especially useful when a black

mark on the back of the paper is combined with preprinted

information that may interfere with the detection of the black mark.

The Start Adjustment is given as a positive or negative number of

dots:

•A positive start adjustment means that the specified length of

paper web will be fed out before the printing starts. According-

ly, the origin is moved away from the forward edge of the copy.

(This has the same effect as a positive FORMFEED statement

before a PRINTFEED statement).

•A negative start adjustment means that the specified length of

paper web will be pulled back before the printing starts. Accord-

ingly, the origin is moved towards the forward edge of the copy.

(This has the same effect as a negative FORMFEED statement

before a PRINTFEED statement).

The Stop Adjustment is set up the same way.

•A positive stop adjustment means that the specified length of

paper web will be fed out after the printing is completed.

Accordingly, the origin is moved away from the forward edge of

next copy. (This has the same effect as a positive FORMFEED

statement after a PRINTFEED statement).

•A negative stop adjustment means that the specified length of

paper web will be pulled back after the printing is completed.

Accordingly, the origin is moved towards the forward edge of

next copy. (This has the same effect as a negative FORMFEED

statement after a PRINTFEED statement).

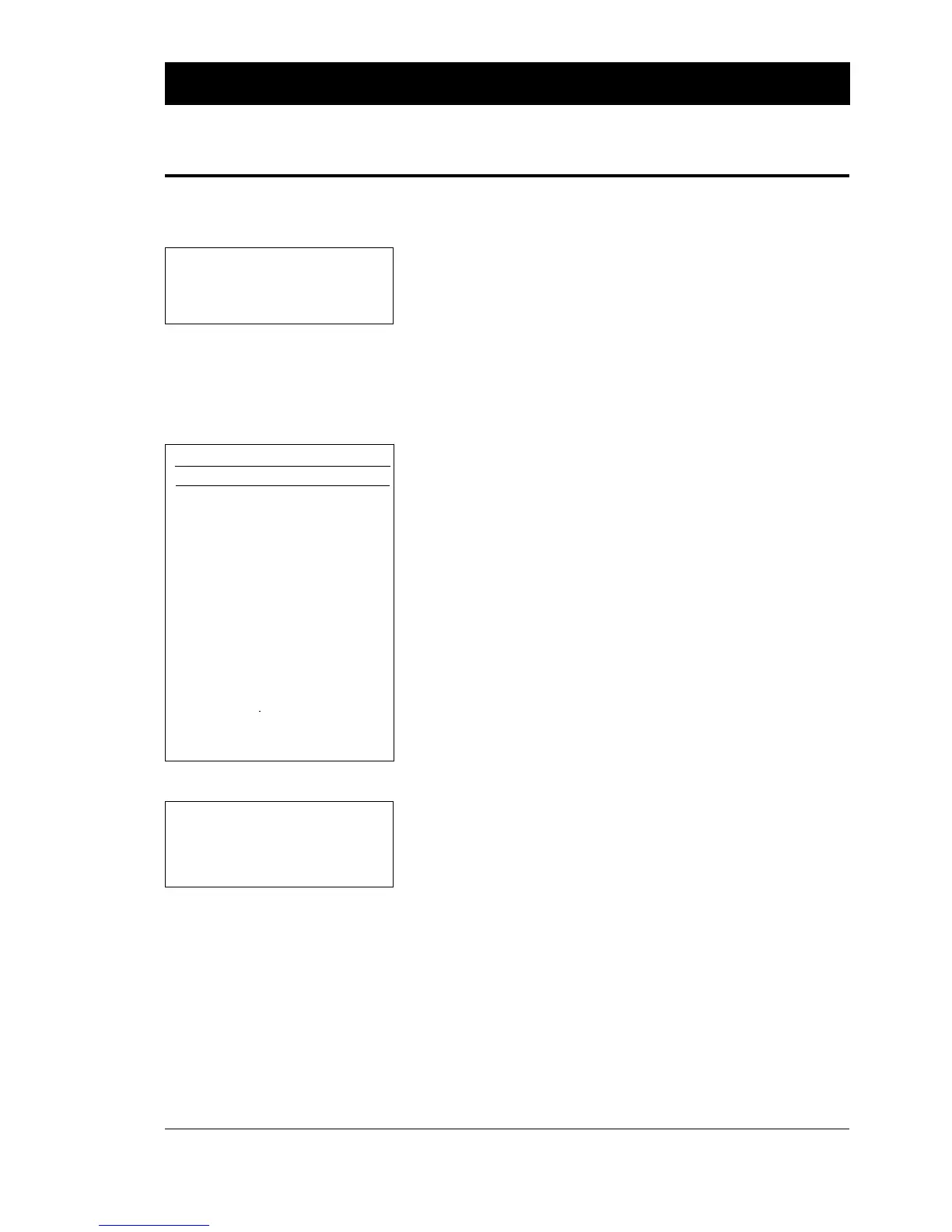

Detection, cont'd.

Rec. adjustments:

Density: 6 dots/mm 8 dots/mm

Peel Off:

Start adjust: -17 -22

Stop adjust: 0 0

Tear Off:

Start adjust: -39 -52

Stop adjust: -23 -30

Strip:

Start adjust: -39 -52

Stop adjust: 0 0

Cut between labels:

Start adjust: -233 -310

Stop adjust: +233 +310

Cut var. length strip:

Start adjust: -233 -310

Stop adjust: +210 +280

6 dots/mm (153.9 dpi):

1 dot = 0.165 mm = 6.5 mils

8 dots/mm (203.2 dpi):

1 dot = 0.125 mm = 4.9 mils

For more information on the instructions

FORMFEED and PRINTFEED, see

Intermec Fingerprint Reference Manual

or Intermec Direct Protocol Programmer's

Guide.

Loading...

Loading...