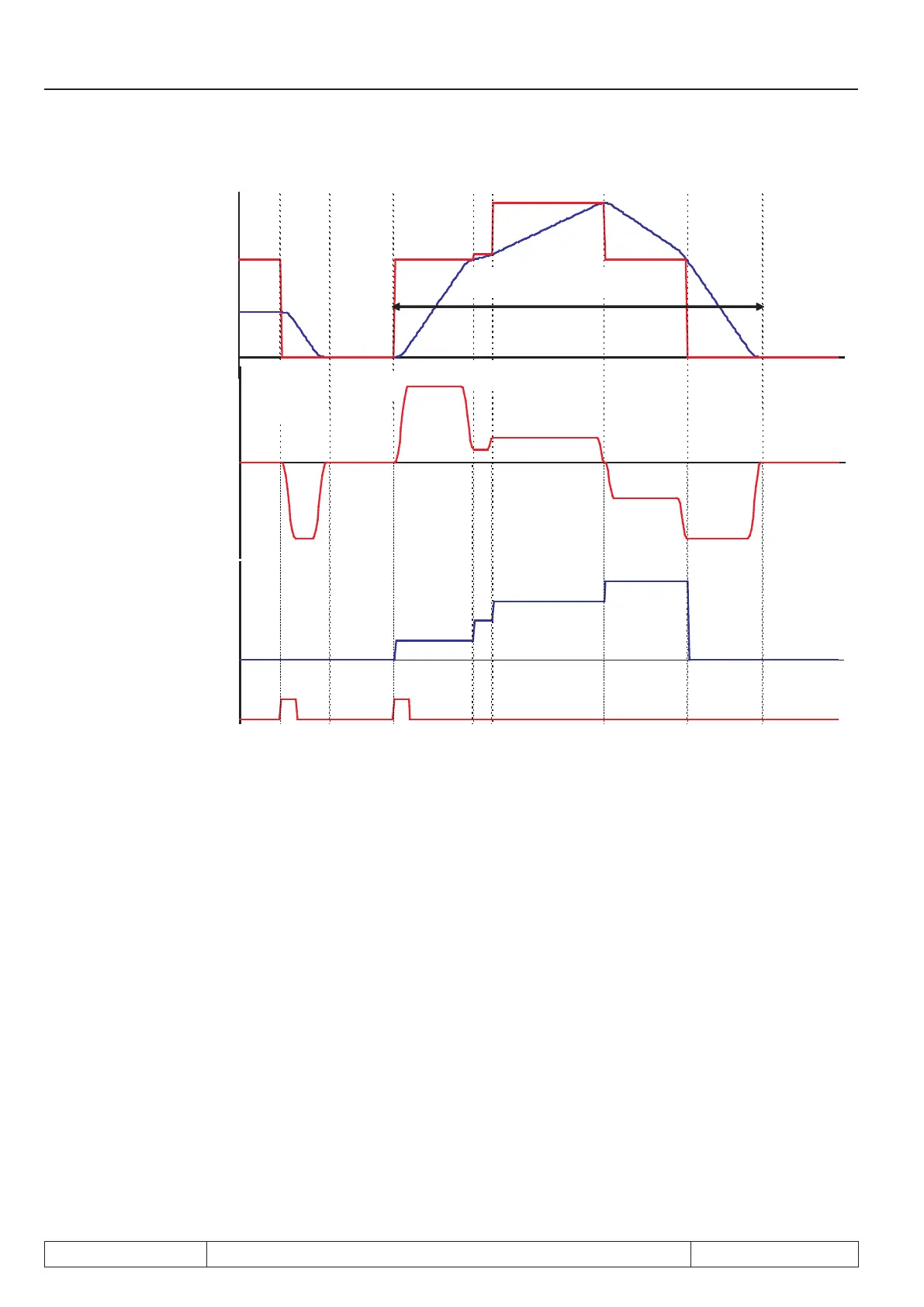

ru.56: Set

position

ru.61: tar-

get position

ru.02: ramp output

display

(= setpoint speed

controller)

Start posi-

tioning

act. positi-

on index

driving free

from the

material

automatic operation of the drilling prole

Retraction

to starting

position

penetra-

tion

Advance to

material

surface

waits for

start positio-

ning

Retrac-

tion to

starting

position

In the example above, the drive did not stop after each step in the drilling process, instead, the target position

of the individual steps was crossed already at the speed set for the next drilling step. I.e., the parameter PS.25

"index/ speed" denes the positioning speed for a block, while the value of PS.25 of the following block deter-

mined the speed at which the target position is crossed.

For example: the "penetration block" is block 2. The speedduring penetration (positioning speed) is the value

of PS.25 in block 2 = 250 rpm.

The drilling is to continue with 500 rpm, so the drive already accelerates at the end of the penetration to the

drilling speed of 500 rpm, i.e., the value of PS.25 in block 3. The speed at which the target of block 2 is passed

(= the target speed) is also determined by block 3 (the following block).

If the drive has to reverse to reach the next target (change the direction of rotation) or if the next target shall

not be driven to automatically (PS.27: "continuation of the prole processing" = no), the target speed of a block

automatically becomes 0 (standstill at target).

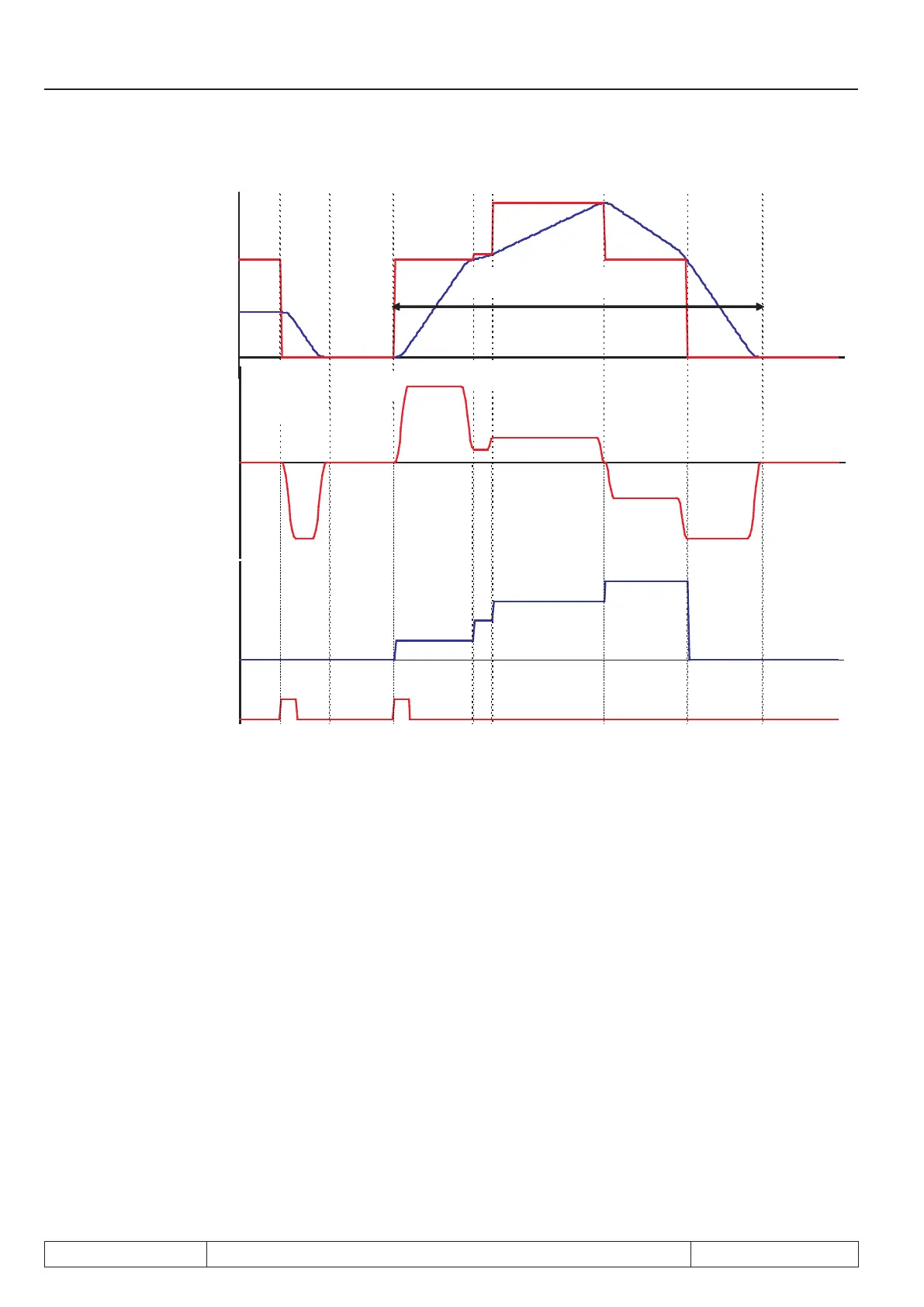

Example 2: Positioning of a workpiece for various processing steps / sequence control by external

control

Sequential positioning with stop between the positioning steps and denition of the prole speed by PS.25.

Page 7.12 - 44 COMBIVERT F5-A, -E, -H © KEB, 2012-10

Posi- and synchronous operating

Loading...

Loading...