burning loss in the surface.

Clean the metal powder on the surface of the commutators.

Conduction check between all interfaces of other components

Make sure armature shafts of all interfaces could not turn on.

Conduction check of the outer cover of the starting motor.

Make sure the conduction terminator and the

outer cover of the starting motor could not turn on.

Conduction check between conduction terminators and electric brushes.

Change for a new one if there is anything abnormal.

Conduction measuring of the electric brush bracket.

Change for a new one if it turns on.

Measuring of the length of electric brushes.

Available Credit:change those below 3mm.

Check whether the needle bearing in the front

cover is rotating smoothly and whether there is

any loose when pressed in.

Change for a new one if there is anything abnormal.

Check whether there is any wear or damage of the oil seal.

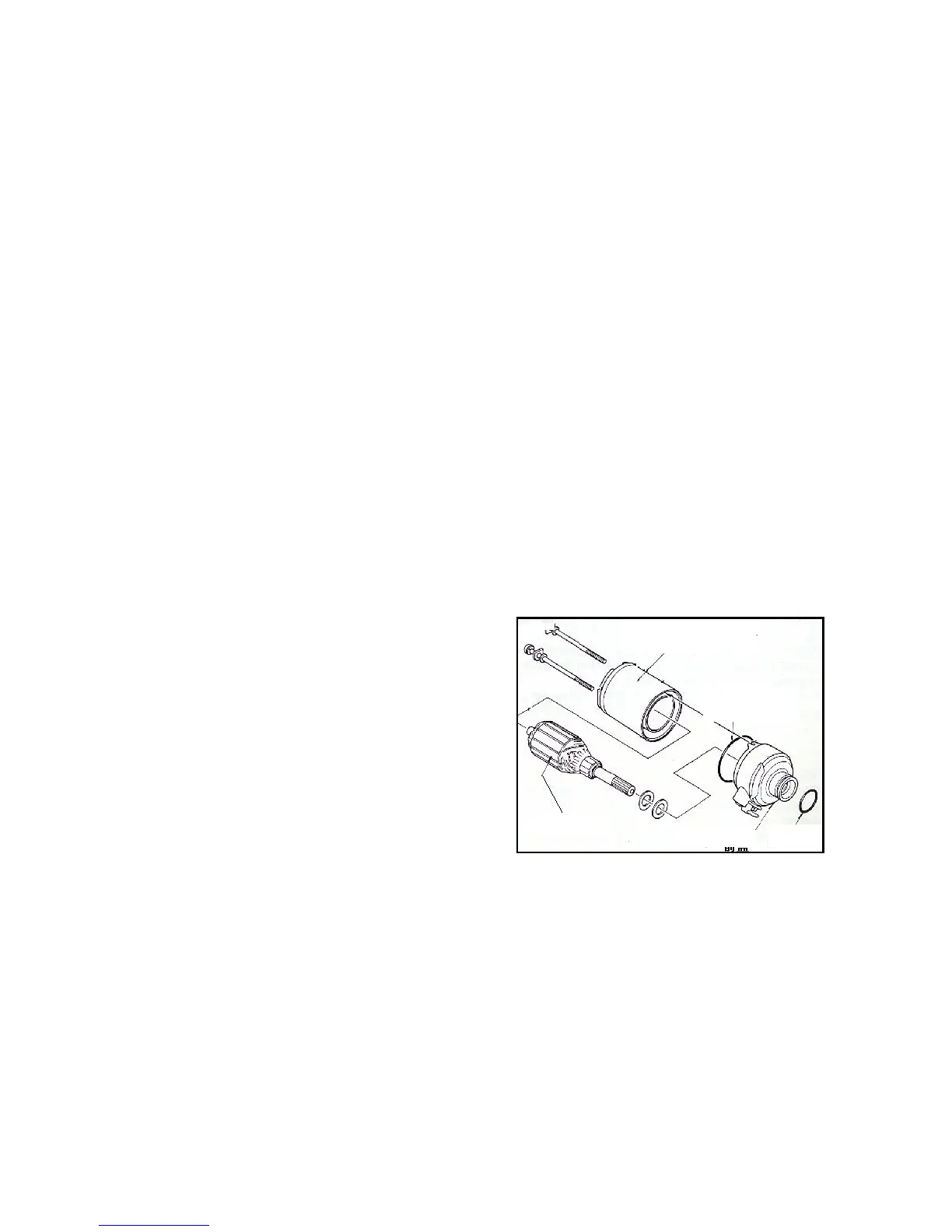

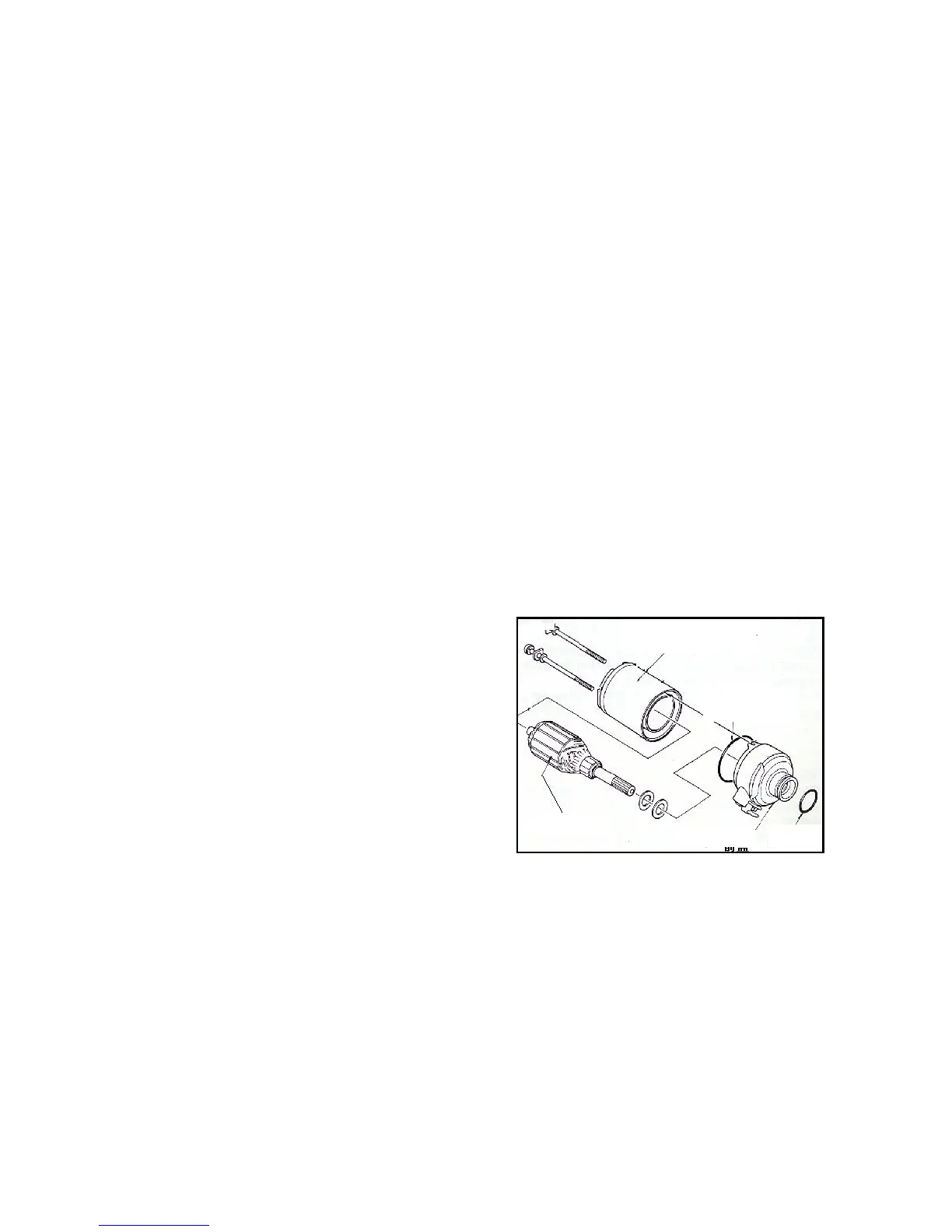

3.3.4 Assembling

Oil seal and greasing coating in the front cover.

Install the electric brush on the electric brush bracket.

Grease coating on movable parts of the two ends of electric

brush.

Press all the electric brushes into the bracket, then fit on the

front cover of the electric motor.

* Note

• Damage is not allowed in the interface between the electric

brush and the armature, pay attention please.

• The labial part of the oil seal should not be damaged by the

installation shaft, pay attention please.

Install new O-rings on the front cover.

Pair the screw of the motor shell with the one of the front cover

during installation.

Screw up the screw in the outer shell.

* Note

In the assembling of the outer shell and the front cover,

use the magnet to draw the front cover to make it easy to

pull out the armature, and then press it down softly.

Loading...

Loading...