Safety temperatures

The boilers comply with EN 303 and DIN 4702, and are all CE-desig-

nated and can be used in sealed heating systems as per EN 12828.

■ Permissible flow temperatures (= safety temperatures):

up to 110 ºC

To EN 12953: up to 120 ºC

■ Max. possible flow temperature:

approx. 15 K below the safety temperature

■ High limit safety cut-out of the boiler control unit:

Delivered condition 110 ºC

Adjustable to 100 ºC

6.2 Delivery

KÖB delivers to the site. The system is unloaded on site.

A special crane is required on site for unloading.

The personnel carrying out transportation must be aware of accident

hazards and take appropriate measures to prevent them. The boiler

should only be lifted when it is completely empty (water, fuel, ash).

Pyrot with a rated output of 100 – 300 kW: lift by lifting eye.

Pyrot with a rated output of 400 – 540 kW: lift by flow and return con-

nectors with tie-bar.

6.3 Handling

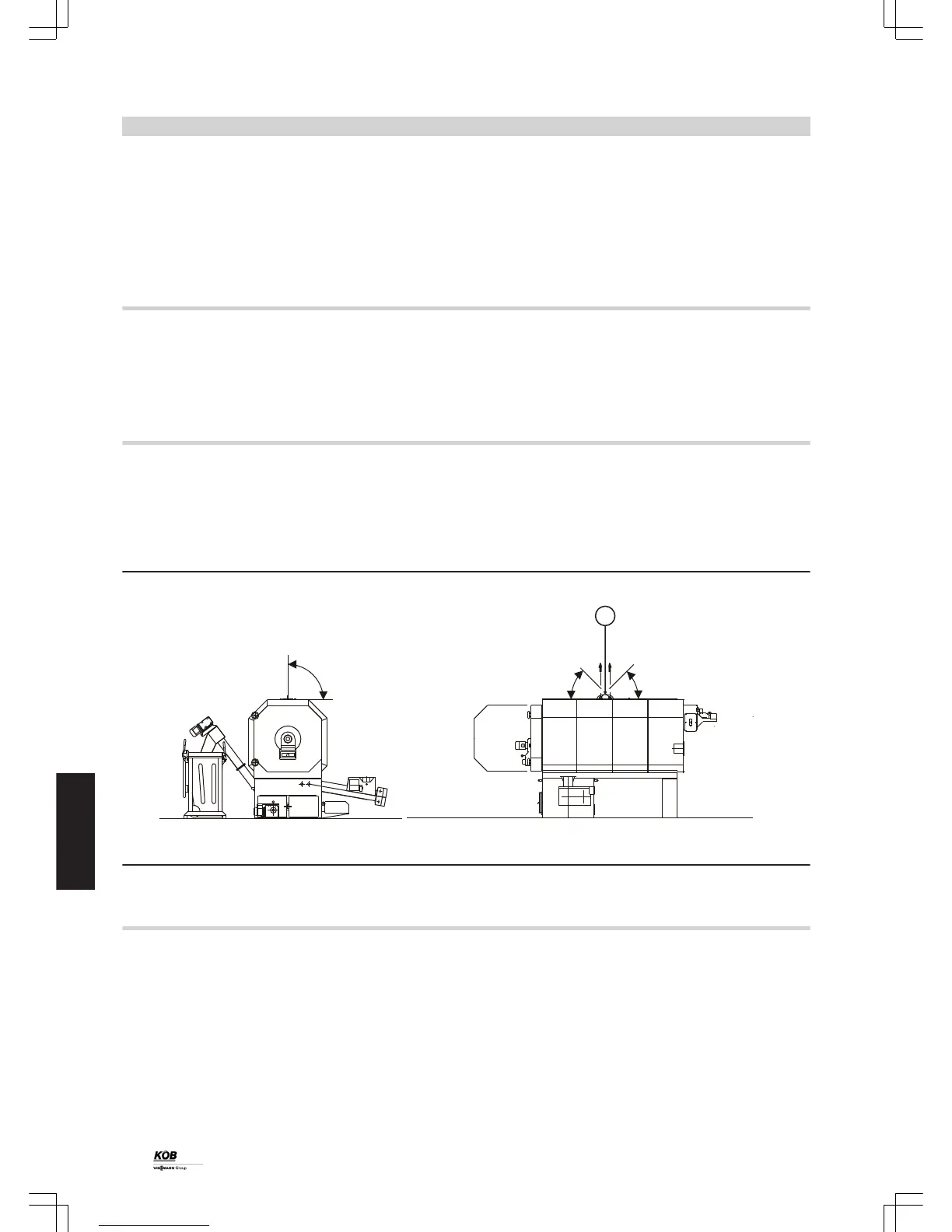

A number of lifting eyes will be provided on each boiler and flue gas/

water heat exchanger where lifting gear may be attached.

To lift the boiler by the flow and return connectors, a tie-bar is

required.

Our experts can undertake the handling and installation on prepared

foundations upon request (chargeable option).

The boilers may be placed onto concrete without special foundations.

Observe the installed boiler height.

Minimum clearances to walls for installation and maintenance work

must be observed.

Anti-vibration boiler supports may be used if anti-vibration measures

are required.

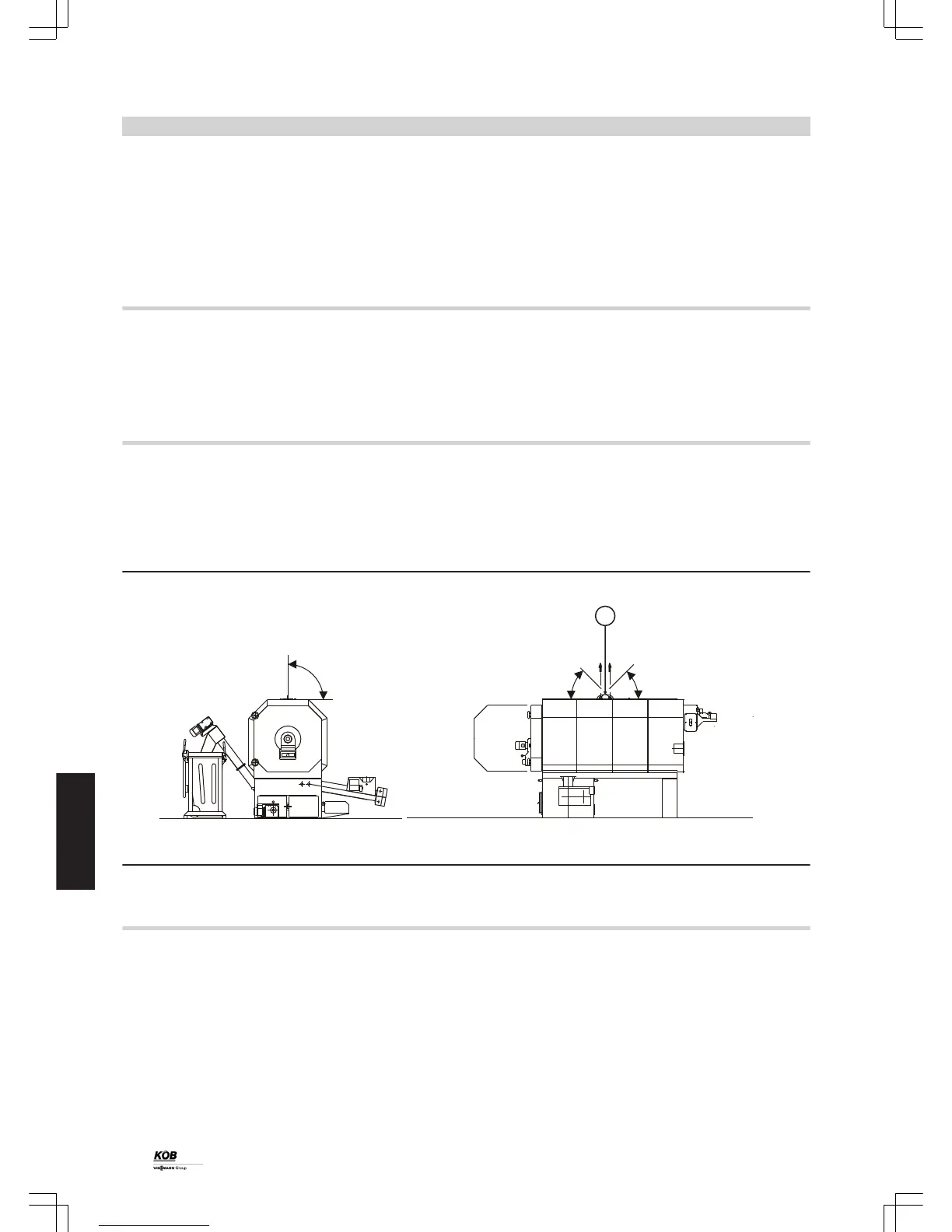

A

Lifting eyes

(for Pyrot 400-540 kW, a tie-bar is required.)

6.4 Siting

Requirements for boiler room

A separate dry boiler room must be provided for the system. No com-

bustible materials should be stored in the boiler room. The wood boiler

may only be installed on a fire and temperature-resistant floor. No

temperature-sensitive pipes or lines should be routed under the floor

under the boiler. The load bearing capacity of the boiler room floor

should be sized to the system weight plus the water fill volume and the

fuel. Floor load bearing capacity in the area of the boiler supporting

surface: 2000 kg/m².

The minimum clearances from walls and the ceiling, which are required

for cleaning and maintenance, must be observed. These can be found

on the measurement sheet. An adequate fresh air supply directly from

outside into the boiler room must be ensured. If the boiler room is nar-

row and/or internal, forced ventilation is required. The temperature in

the boiler room when operating the system must not exceed +40 °C

(measurement point: boiler environment approx. 1 m away from

boiler). The temperature in the boiler room when operating the system

must not fall below +10 °C (measurement point: inner side of external

wall).

Design information

(cont.)

42

PYROT

6

5822 516 GB

Loading...

Loading...