■ Avoid air contamination through halogenated hydrocarbons (e.g. as

in sprays, paints, solvents and cleaning agents)

■ Avoid very dusty conditions

■ Avoid high levels of humidity

■ Prevent frost damage and ensure good ventilation

In rooms where air contamination through halogenated hydrocar-

bons can occur, install the boilers and flue gas/water heat exchangers

only if adequate measures can be taken to provide a supply of uncon-

taminated combustion air.

If these instructions are not observed, any consequential losses

directly related to any of these causes are excluded from our war-

ranty.

If in doubt, please contact us.

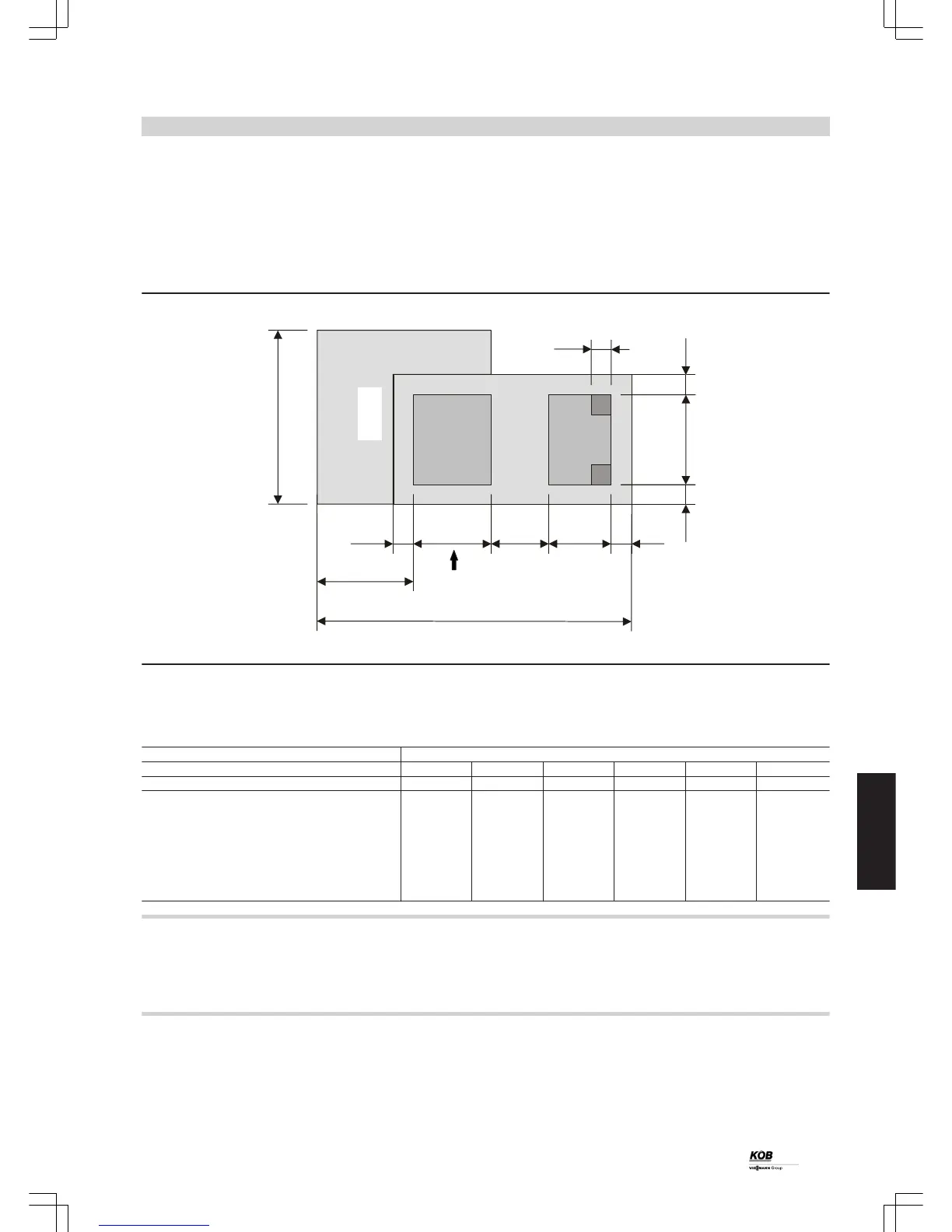

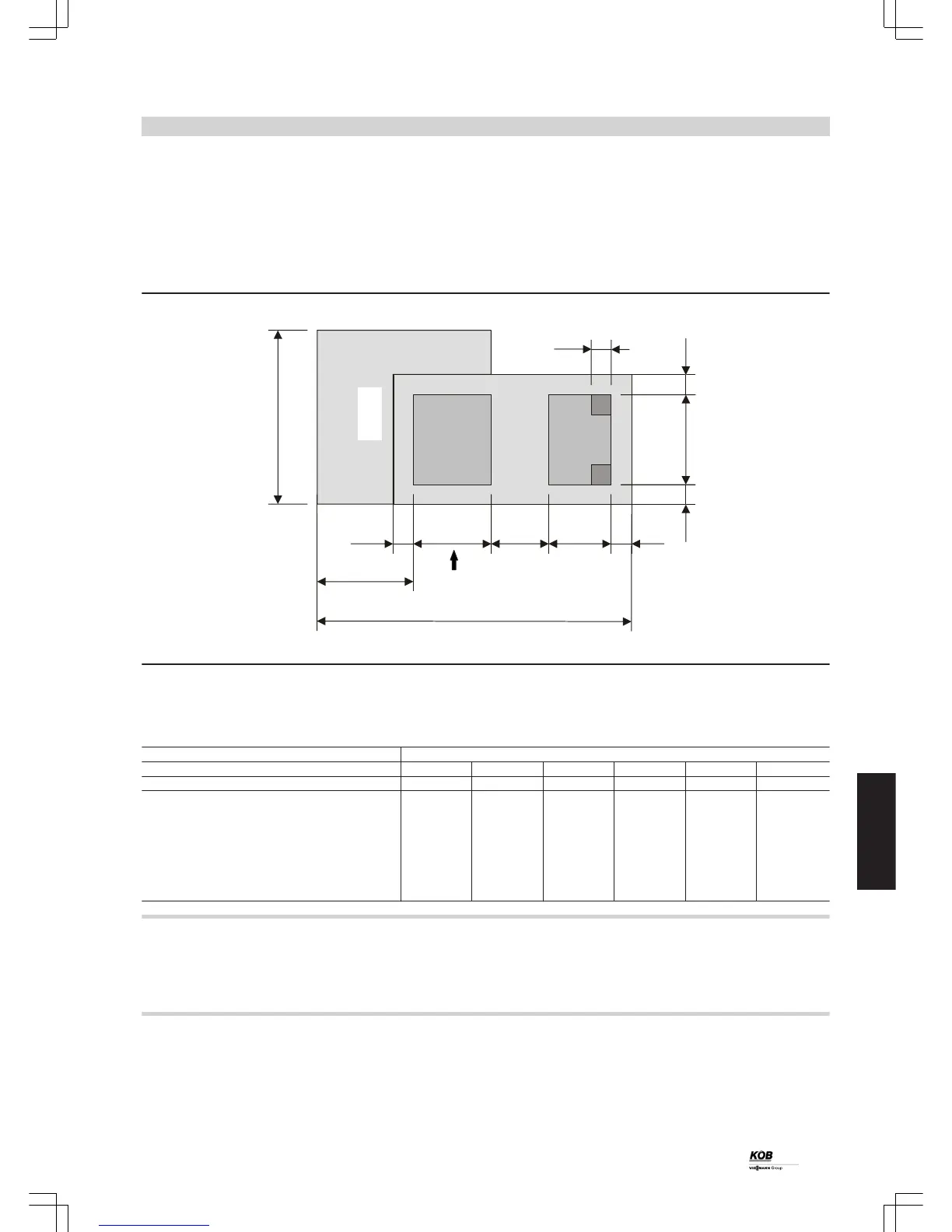

x Supply side

y Floor in heat-resistant version

Surface medium grey Boiler supporting surface

Foundation properties

Trade name Pyrot rotation combustion

Rated output kW 100 150 220 300 400 540

Part no.: 7423 656 7423 657 7423 658 7423 659 7423 660 7423 661

Dimensions

a mm 1570 1570 2050 2050 2460 2460

b mm 870 870 1150 1150 1390 1390

c mm 620 620 680 680 800 800

d mm 2803 2850 3130 3613 3738 4103

e mm 423 520 520 723 448 543

f mm 640 740 740 880 960 1095

g mm 870 870 1150 1150 1390 1390

Requirements of the Muster-Feuerungsverordnung [Germany]

The installation room must meet the standards laid down by the "Mus-

ter Feuerungsverordnung" [Germany]. Observe the Building Regula-

tions and combustion equipment ordinances of the relevant country of

installation.

Combustion air supply

For open flue combustion equipment with a total rated output in excess

of 35 kW, the combustion air supply is deemed to have been verified

if the combustion equipment is located in areas which provide an aper-

ture or duct leading outdoors.

At 35 kW rated output, the cross-section of the aperture must be at

least 150 cm

2

. For every kilowatt rated output in excess of 35 kW, the

aperture must be 2 cm

2

larger than stated above.

Pipes must be sized to provide equivalent flow rates. The required

cross-section may be split over a maximum of 2 apertures or pipes.

Design information

(cont.)

PYROT

43

5822 516 GB

6

Loading...

Loading...