Replacement, expansion vessel

An additional expansion vessel and discharge pipe are not required if

a second high limit safety cut-out and a second maximum pressure

limiter are installed.

6.8 Fire protection

The fire safety regulations for wood combustion systems vary depend-

ing on the country.

The regulations valid for the relevant installation location must be

observed.

Fire safety, fuel store

The measures required for this are not part of the standard delivery of

KÖB Holzheizsysteme GmbH.

Note

In this regard, the conditions of the local planning office must be fulfilled

by the operator.

6.9 Commissioning

Initial commissioning of a newly installed system may only be carried

out by KÖB Holzheizsysteme GmbH or another contractor trained and

authorised by KÖB. Prior to commissioning, the system must be filled

with water, fuel must be stored for the commissioning and the instal-

lation must be monitored.

Fuel for commissioning

As the boiler system is cold and residual moisture is also extracted

from the refractory concrete during commissioning, the fuel for com-

missioning must be at least air dry. The heat-up process should be

carried out in the first three hours with low output. In order to check the

function of the silo discharge system, not too much fuel should be

stored so that, in the event of a fault, the discharge system can be

quickly released to remedy the cause. For commissioning, dry fuel

(max. w 20 %) should be stored in sufficient quantity for approx. 10 –

24 full operating hours.

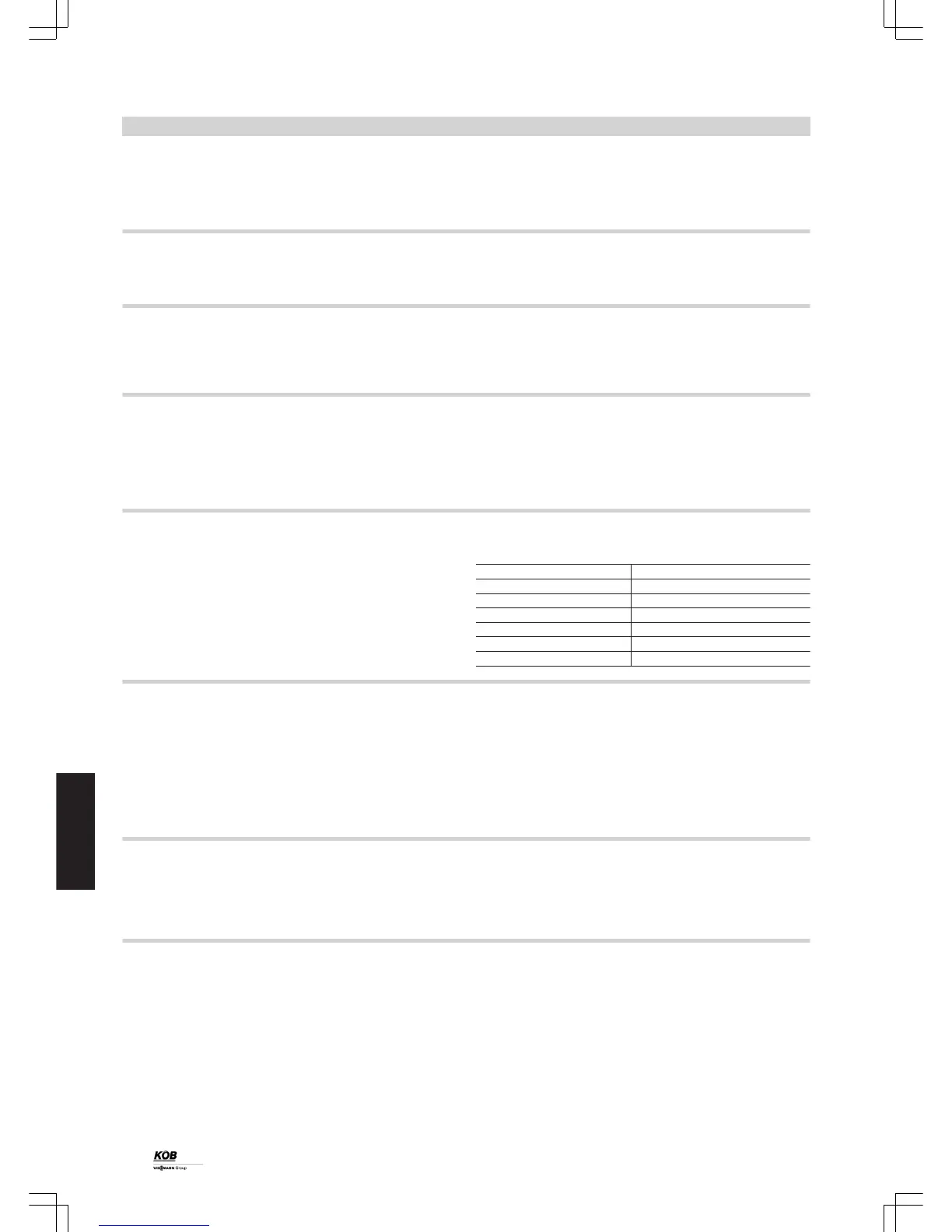

Fuel quantities to be stored for commissioning:

Rated output Quantity

100 kW approx. 800 kg

150 kW approx. 1200 kg

220 kW approx. 1500 kg

300 kW approx. 2000 kg

400 kW approx. 2500 kg

540 kW approx. 3000 kg

Filling the heating system

Usually, the system is initially filled with raw water without chemical

treatment. This must be filtered and be free of suspended solids. Par-

ticular attention should be paid to careful ventilation during filling. In

the case of difficult water conditions (high hardness, etc.) and/or large

water volumes, VDI directive 2035 "Prevention of damage through

corrosion and scaling in hot water heating systems" must be observed.

Measures recommended by the directive for water treatment should

be carried out.

Note

The fill pressure of the cold hydraulic seal should be approx. 0.1 bar

higher than the pre-charge pressure of the sealed expansion vessel.

However, it must not exceed a maximum of 3 bar.

6.10 Fuels

The Pyrot was developed for processing dry wood remnants from the

wood processing industry. This includes dry residual wood, shavings,

sawdust, etc. and conditioned fuels (high grade, homogeneous quality

fuels). The combustion system is ideal for the combustion of pellets.

Suitable fuels

The Pyrot is suitable for the following dry to moist wood fuels: ■ Woodchips from forests up to a water content of 35 % (W35, G50)

■ Industry pellets, with an ash content of max. 1.0 %

■ Pellets with the quality seal DINplus or acc. to ÖNORM M 7135

Note

The following are unsuitable types of fuel: fossil fuels and those con-

taining sulphur, such as anthracite and coke, as well as plastics,

grain, straw, material soaked in flammable liquids and wood rem-

nants treated with plastics or wood preservatives.

Design information

(cont.)

50

PYROT

6

5822 516 GB

Loading...

Loading...