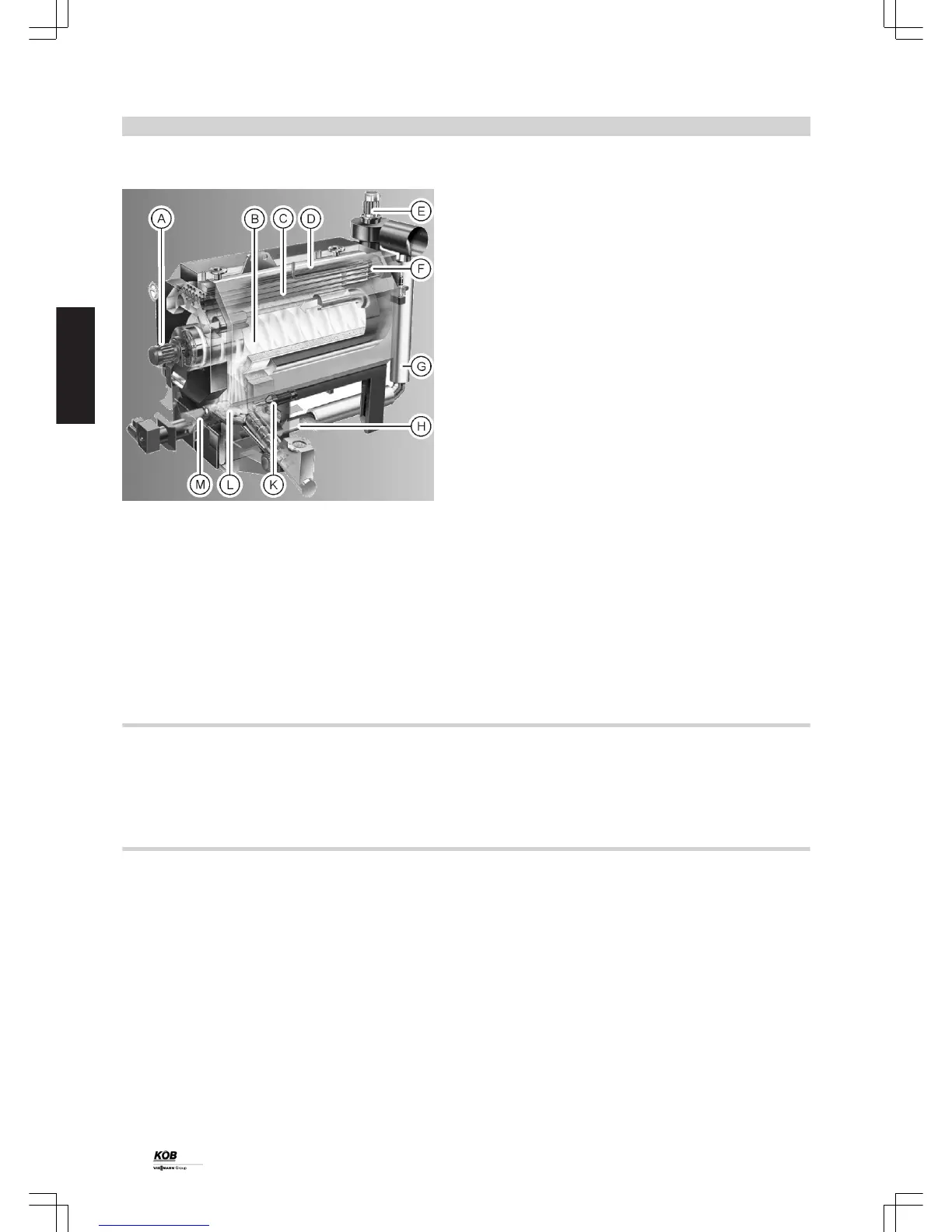

2.1 Product description

A

Controlled secondary air with rotary fan

B

Rotary combustion chamber

C

Boiler heat exchanger

D

Safety heat exchanger

E

Flue gas fan with Lambda probe and temperature sensor

F

Pneumatic cleaning

G

Flue gas recirculation, controllable

H

Regulated primary air

K

Ignition fan

L

Fully moving grate

M

Ash removal

With its patented rotation combustion, the Pyrot wood boiler repre-

sents state of the art wood combustion. A supply screw conveyor con-

tinuously guides the wood fuel onto a moving grate on which the fuel

combustion takes place. Continuous gasification takes place under air

starvation. A rotary fan is used to mix rising combustion gases with the

secondary air displaced in a rotary motion. This ensures thorough

mixing with the combustion gases.

Clean and efficient combustion

The proven combustion technology in the Pyrot achieves similar emis-

sions values to those of a modern gas combustion system and keeps

the release of CO, NOx and dust particles to a minimum, subject to

fuel type. The combination of combustion technology and digital mod-

ulating output control enables efficiency levels of up to 92 %.

Mobile containerised heating centre

Pyrot wood boilers are available as containerised complete solutions

for uses where there are no boiler houses available or where the on-

site building costs have to be reduced to a minimum. This complete

solution incorporates the pre-assembled wood boiler inside a special

container with all ancillary devices. In addition to finished container

solutions, individual versions can be specially matched to your

needs.

Benefits at a glance

■ High efficiency levels (up to 92 %) and low emissions through regu-

lated primary and secondary air supply and low particle combustion

■ Two-pass heat exchanger and modulating output control (4:1 control

range)

■ Automatic ignition prevents having to maintain the incandescent bed

and saves fuel

■ Easy service thanks to fully automatic ash removal, optional pneu-

matic cleaning system and flue gas dust extractor

■ Highly developed safety devices ensure a safe and reliable opera-

tion

■ Individual planning of your system by our team of experts

■ Available as a complete ready-to-use containerised solution

Delivered condition

Pre-assembled steel boiler for wood pellets and woodchips according

to DINplus and ÖNORM M 7135.

Combustion chamber door, ash doors, ash boxes, cleaning device.

1 supply screw conveyor with separating barrier, incl. extinguishing

valve with dirt trap

1 flue gas fan

1 extinguishing water container with holder

1 automatic ignition system

1 set displacer rods

1 recirculation gas device

1 secondary air device (draught stabiliser); for on-site installation in the

flue pipe

Sensors:

■ Infrared light barrier for level monitoring, separating barrier, supply

screw conveyor

■ Safety limit switch on inspection cover of supply screw conveyor

■ Contact sensor Pt100 at the supply screw conveyor

■ Infrared light barriers for level monitoring of the fuel in the combus-

tion chamber

■ Zirconium dioxide probe with measured value transducer

■ Flue gas temperature sensor PT-100

■ Return temperature sensor KTY

■ Boiler water temperature sensor KTY

■ High limit safety cut-out (STB)

■ Temperature sensor, rotary fan

■ Sensor KTY with sensor well

PYROT rotation combustion

8

PYROT

2

5822 516 GB

Loading...

Loading...