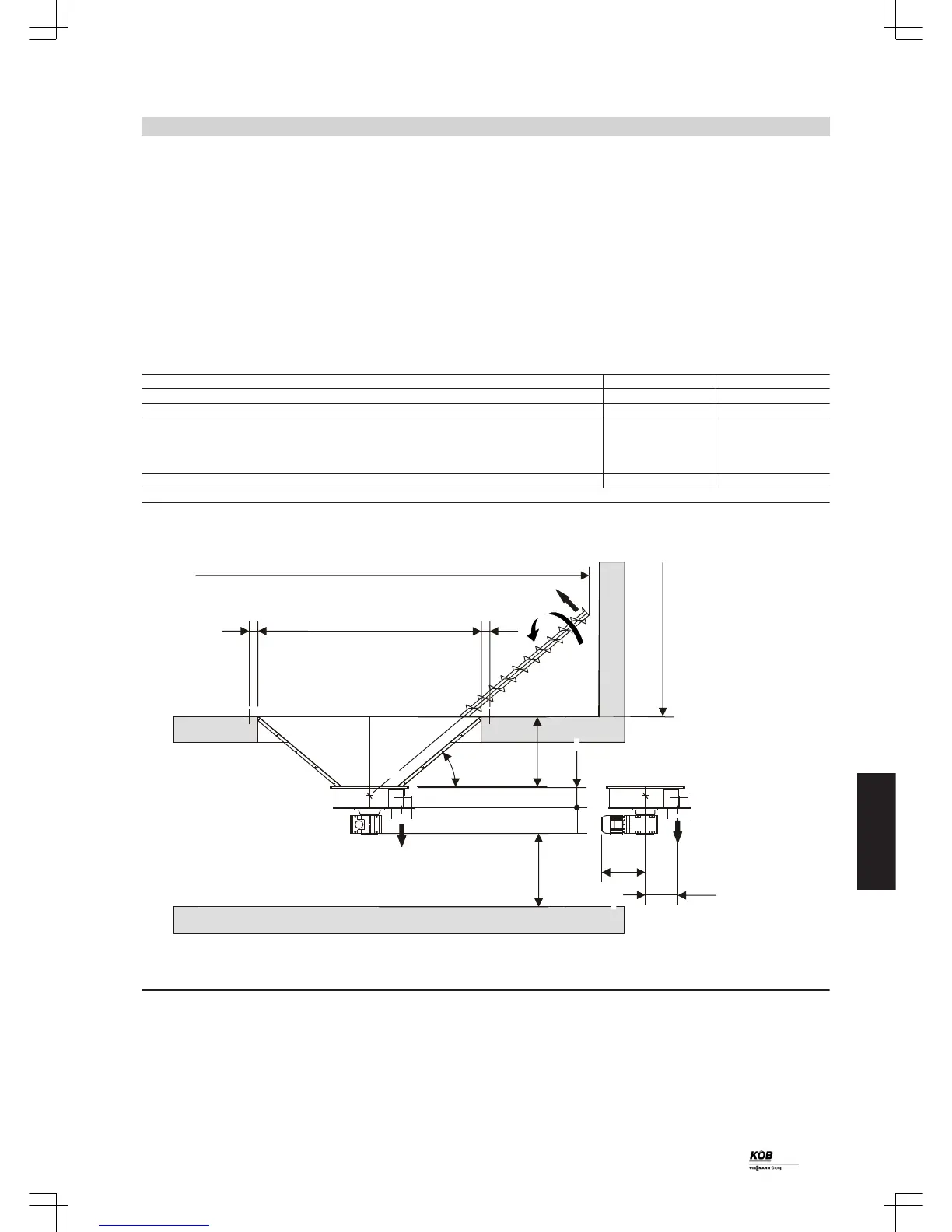

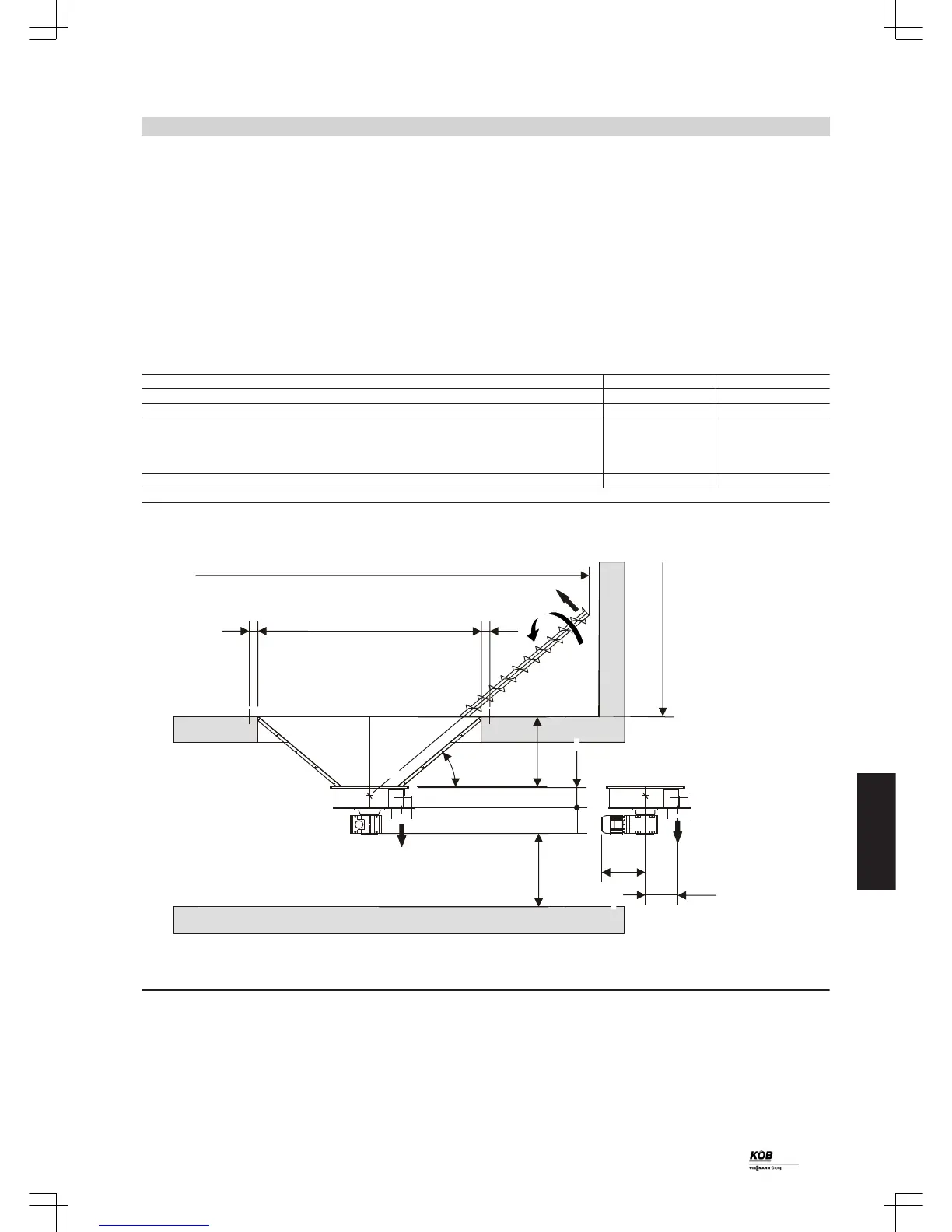

6.13 Fuel discharge by means of funnel discharge

Funnel discharge

Material discharge for round silos is carried out with an agitator inte-

grated in the discharge casing. In its centre, the discharge screw con-

veyor is driven via a solid universal joint. When the silo is full, the screw

conveyor moves into a vertical position. The funnel limits the angle of

the screw conveyor when the silo is empty. Drive is via a spur geared

screw conveyor motor to the agitator. In the case of material compres-

sion in the discharge casing, as a result of increased drive power con-

sumption, the supply direction of the screw conveyor is changed auto-

matically for a period set at the factory. This releases the compression,

preventing a fault.

Standard delivery:

■ Funnel discharge as per order data with drive unit 3 x 400 V

■ Automatic control of the drive for the spur geared screw conveyor

motor for both rotational directions

■ Safety limit switch installed on inspection cover of discharge casing

Version and drives

Funnel discharge AP-11 AP-12

Part no. 7837 794 7837 958

Diameter discharge circuit max. m 6.0 7.5

Boiler outputs with

Pellets S 650 kW 3000 2500

Woodchips from forest S 200 kW 1250 2500

Shavings S 130 kW 1250 2500

Torque at screw conveyor Nm ~1500 ~3000

Loading...

Loading...