Selection example

Datum:

p

sv

= 3 bar (response pressure of the safety valve)

H = 13 m (static ceiling of the system)

Q = 18 kW (rated output of the heat source)

v = 8.5 l/kW (specific water capacity)

panel radiators 90/70 °C

V

PH

= 1000 l (volume of buffer cylinder)

The specific water capacity v was determined as follows:

■ Radiators: 13.5 l/kW

■ Panel radiators: 8.5 l/kW

■ Underfloor heating: 20 l/kW

Calculation:

V

A

= Q x v + 1000

V

A

= 18 kW x 8.5 l/kW + 1000 l

= 1153 l

If possible, when calculating the gas pre-charge pressure, select a

supplement of 0.2 bar:

p

0

≥ H/10 + 0.2 bar

p

0

≥ (13/10 + 0.2 bar) = 1.5 bar

From the table:

With p

sv

= 3 bar, p

0

= 1.5 bar, V

A

= 1153 l

V

n

= 250 l (for V

A

max. 1360 l)

Selected:

1 x diaphragm expansion vessel N 250 (from Vitoset pricelist)

■ All details relate to a flow temperature of 90 °C.

■ The tables have allowed for a hydraulic seal to DIN 4807-2.

Recommendations:

■ Select a sufficiently high safety valve response pressure:

p

sv

≥

p

0

+ 1.5 bar

■ For circulation pumps, due to the inlet pressure required, select at

least 0.3 bar above the pre-charge pressure even for attic/roofspace

installations: p

0

≥

1.5 bar

■ Set the water side filling/starting pressure of vented systems in their

cold state at least 0.3 bar above the pre-charge pressure:

p

F

≥

p

0

+ 0.3 bar

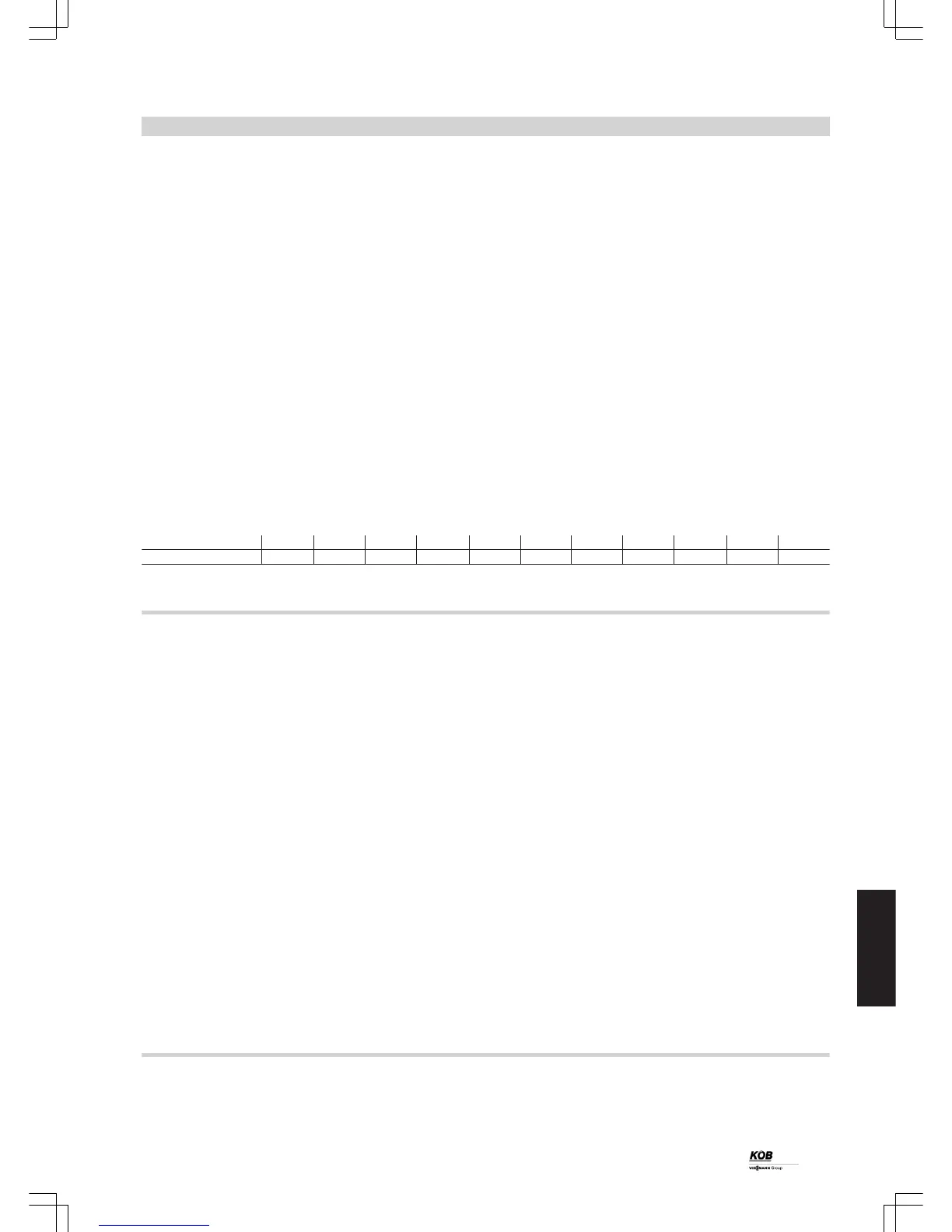

Conversion factor for flow temperatures other than 90 °C

Flow temperature °C 50 55 60 65 70 75 80 85 90 95 100

Conversion factor 3.03 2.50 2.13 1.82 1.59 1.39 1.24 1.11 1.00 0.90 0.82

Divide the vessel size found in accordance with the above tables by the conversion factor.

7.2 General information regarding low pressure hot water boilers with safety temperatures

of up to 110 ºC

The pressure equipment (hot water boiler) has been built in accord-

ance with TRD 702 and should be equipped in line with that Directive.

Observe the operating conditions in that Directive. Subject to type, this

boiler meets the following standards regarding its stated rated output

and technical requirements:

■ DIN 4702 or EN 303

■ EN 297

■ EN 483

■ EN 677

(See details on the type plate and the enclosed documentation). Dur-

ing installation and commissioning of this wood boiler, observe all local

Building Regulations and regulations concerning combustion systems,

as well as the following Standards, Regulations and Directives:

■ DIN 18160-1: Flue system (design versions)

■ DIN 1988: Technical Regulations for Drinking Water Installations

(TRWI)

■ DIN 4753: DHW systems for DHW and process water

■ EN 12828: Heating systems in buildings – design of DHW heating

systems

■ EN 13384: Flue systems – Thermal and flow calculations

■ TRD 702: Equipment level for steam boiler systems with hot water

boilers class II

■ Also observe EN 12953 with:

– Low pressure hot water boilers with safety temperatures > 110 to

120 ºC

■ EN 12953-1: Boilers with large water chambers – general informa-

tion

■ EN 12953-6: Boilers with large water chambers – Equipment

requirements

■ EN 12953-7: Boilers with large water chambers – Requirements for

combustion systems for liquid or gaseous fuels for the boiler

■ EN 12953-8: Boilers with large water chambers – Safety valve

requirements

■ EN 12953-10: Boilers with large water chambers – Feed water and

boiler water requirements

Use of oil combustion

■ DIN 4755: Oil combustion equipment

■ DIN 4787-1: Atomising oil burner (in excess of 100 kg/h throughput)

■ DIN 51603-1: Liquid fuels; fuel oil EL, minimum requirements

■ EN 230: Atomising oil burners as mono block version – equipment

for safety, monitoring and control, as well as safety times

■ EN 267: Pressure-jet oil burner

■ TRD 411: Oil combustion for steam boilers (where applicable)

Use of oil combustion

■ EN 298: Burner control units for gas burners and boilers with or

without fans

■ EN 676: Pressure-jet gas burner

■ DVGW Code of Practice G 260/I and II: Technical rules for gas

quality

■ DVGW-TRGI 2008: Technical rules for gas installations

■ TRD 412: Gas combustion for steam boilers (where applicable)

■ TRF 1996: Technical rules for LPG

7.3 Pipe connections

All pipe connections to the wood boiler should be made free from

stress and torque.

Appendix

(cont.)

PYROT

91

5822 516 GB

7

Loading...

Loading...