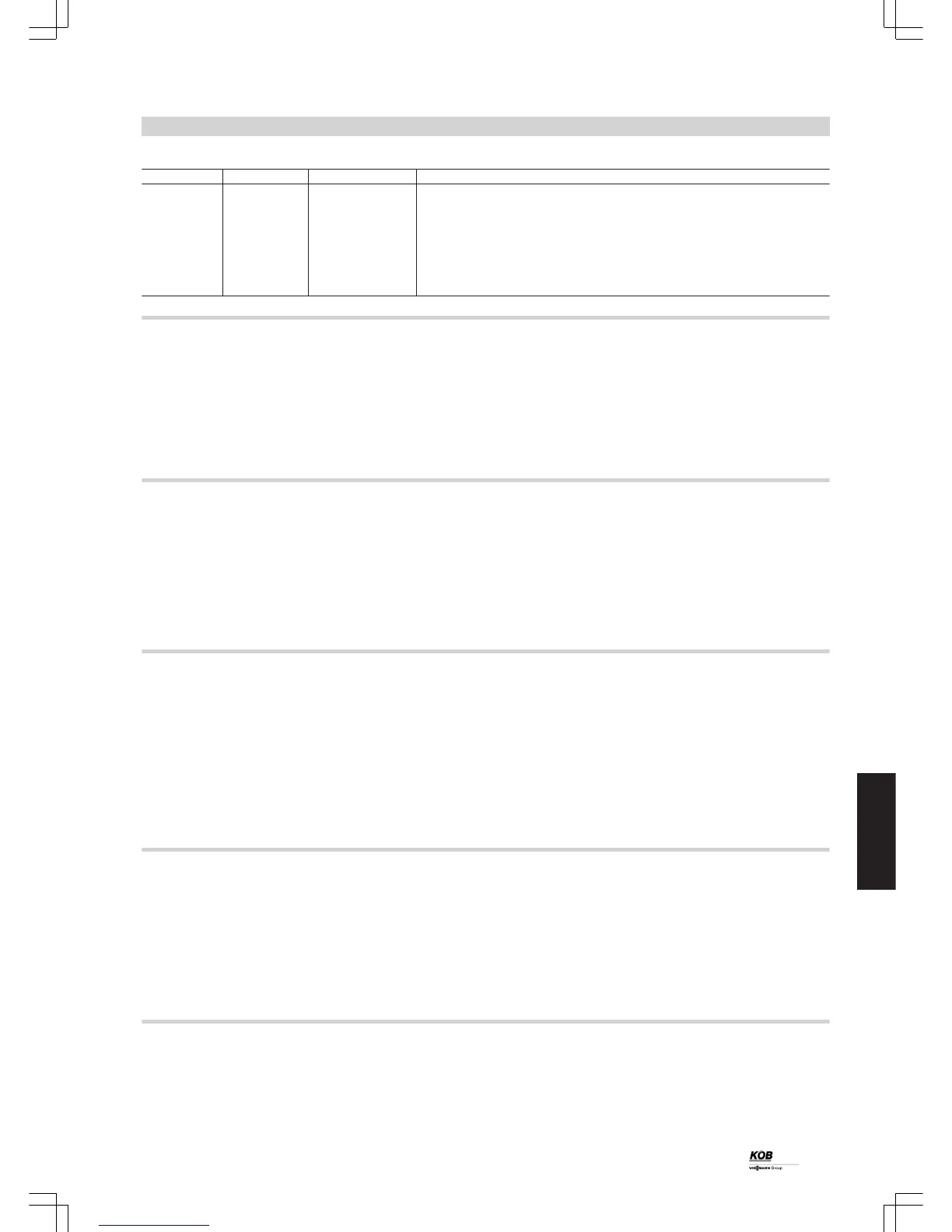

Required order data for the above example:

Position Quantity Unit Designation

A

2 pce Pushrod drive AS twin with hydraulic cylinder type K

B

1 pce Cover for push floor screw conveyor (optional)

C

2 pce Weld base, bunker

D

2 pce Pushrod (incl. stop wedges)

E

1 pce Push floor screw conveyor

F

1 pce Version and drive, AQ standard

G

1 pce Hydraulic drive, ASH twin

H

2 pce Weld base, AS twin

6.15 Fuel discharge by means of push floor (accessory)

Pushrod drive, individual

Part no. 7387 978

With hydraulic cylinders, pushrods to which transport wedges are

attached are moved forwards and backwards. Stop wedges are fixed

to the floor between the transport wedges. As a result of this move-

ment, the wood fuel is dispensed from the bunker and fed into the

trough of the push floor screw conveyor.

Standard delivery:

■ Mount with hinge lug connection for the cylinder

■ Hydraulic cylinder with 2 HP ball valves and 2 hydraulic hoses

■ Pushrod up to bunker wall with hinge lug connection

■ Material for complete hydraulic pipework

Weld base, pushrod drive, individual

Part no. 7387 952

Solid steel structure for installation in concrete to secure the pushrod

drive. The structure has been load tested and permanently withstands

the dynamic stress. A prerequisite for this is the prescribed embedding

in concrete.

Standard delivery:

■ 1 weld base per pushrod drive

To be carried out on customer side:

■ Location, positioning and connecting of the weld base with the iron

reinforcement on the customer side

■ Embedding the weld base in concrete

■ Static calculation and sizing of the iron reinforcement on the cus-

tomer side

Note

Only KÖB original weld bases are permissible.

Pushrod drive, twin

Part no. 7387 915

With hydraulic cylinders, pushrods to which transport wedges are

attached are moved forwards and backwards. Stop wedges are fixed

to the floor between the transport wedges.

In the case of a twin pushrod drive, each longitudinal section of the

bunker is moved with two pushrods working independently of one

another.

■ Charging pushrod for quick removal of the fuel filled at the bunker

end in the direction of the bunker centre

■ Discharge pushrod for the dispensed discharge of the wood fuel into

the trough of the push floor screw conveyor

The two pushrod drives are located one above the other and are sup-

ported by a joint mount.

Standard delivery:

■ Mount for two cylinders with a hinge lug connection

■ Two hydraulic cylinders with 2 HP ball valves and 2 hydraulic hoses

■ Discharge pushrod up to bunker wall with hinge lug connection

■ Charging pushrod up to start of level charging function with hinge

lug connection

■ Material for complete hydraulic pipework

Weld base, pushrod drive, twin

Part no. 7387 916

Solid steel structure for installation in concrete to secure the pushrod

drive. The structure has been load tested. If embedding in concrete

has been carried out in accordance with the regulations, the weld base

permanently withstands dynamic stress.

Standard delivery:

■ 1 weld base per pushrod drive

To be carried out on customer side:

■ Location, positioning and connecting of the weld base with the iron

reinforcement on the customer side

■ Embedding the weld base in concrete

■ Static calculation and sizing of the iron reinforcement on the cus-

tomer side

Note

Only KÖB original weld bases are permissible.

Weld base, bunker

Part no. 7387 830

Steel profiles for welding the pushrod guide elements and the trough

of the push floor screw conveyor. The weld base in the bunker is also

the slide rail for the pushrod.

Standard delivery:

■ Rolled profiles UNP 240 with anchoring irons per pushrod over the

entire length

■ Angle profiles 50/50/5 with anchoring irons over the entire width

(push floor screw conveyor)

Design information

(cont.)

PYROT

67

5822 516 GB

6

Loading...

Loading...