5-24 LeeBoy Model 8515D Conveyor Paver

Maintenance

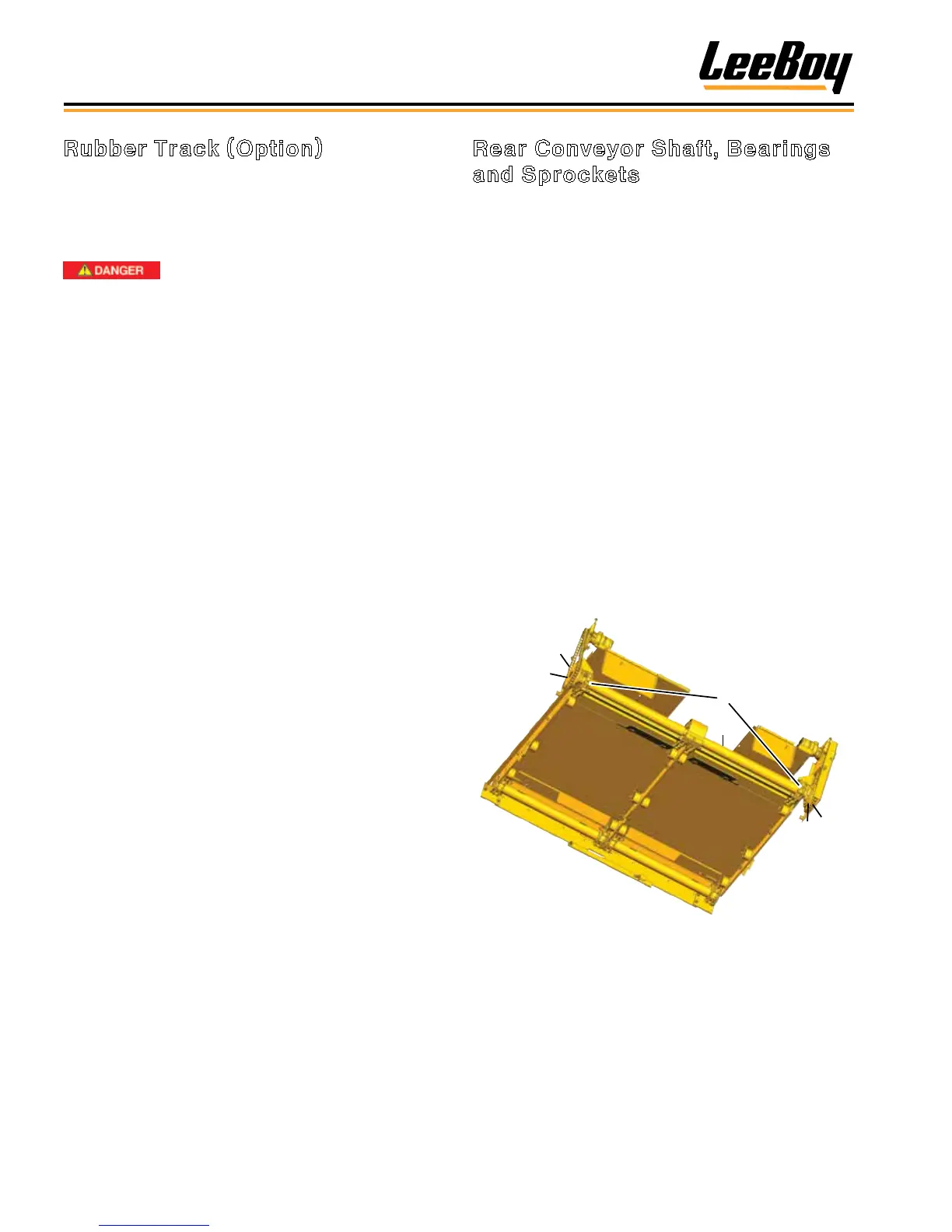

Rear Conveyor Shaft, Bearings

and Sprockets

1. Drive paver onto a ramp to access undercarraige.

2. Disconnect the main conveyor chains. (Figure

5-29)

3. Disconnect any link.

4. Rotate chains away from the assembly.

5. Remove chain from drive motor to the conveyor

sprocket.

6. Remove bolt and washers holding the sprocket.

7. Remove the sprocket and bearing from the frame.

8. Remove bolts on the inner sprocket.

9. Slide out shaft and outer conveyor sprocket through

frame side.

NOTE: Rear tube can be removed for changing the

inner bearings.

NOTE: Remove the inner seals from replaced

bearings in the tubes to allow grease to enter into the

bearing area.

Figure 5-29. Rear Conveyor Shaft

1 - Main Conveyor Chains

2 - Conveyor Chains

3 - Conveyor Sprockets

4 - Conveyor Shaft (inside tubing)

Rubber Track (Option)

1. Raise conveyor and insert safety prop. (Page 5-6)

2. Jack up the paver at least two feet (61 cm) off

the ground for enough clearance under the

undercarraige to perform this procedure.

Crush hazard! Always use safety

blocks in addition to jack when working under the

paver to prevent serious injury or even death.

3. Loosen the track tension cartridge at the manifold

located at rear of the bottom hydraulic tank.

4. Label and disconnect the track tensions hoses from

undercarriage at track tension manifold.

5. Cap and plug all hoses.

NOTE: Remove generator cord at generator if

removing left undercarriage (electric heat

screed only).

6. Remove the two (2) bolts holding the drive motor

to the torque hub. (Figure 5-28) Support the

undercarriage with a forklift or jack before lowering

to the ground.

7. Unbolt the two (2) trunnions on the front of track

undercarriage and stops at each side of the rear of

the undercarriage.

8. Lower the track assembly.

9. Remove rubber track by prying from the idler end

rst.

10. If needed, replace idler, torque hub, sprocket,

rollers and/or cylinder. Lower the undercarriage for

replacing above components, except rollers.

Loading...

Loading...