55

LeeBoy Model 8515D Conveyor Paver 5-25

Maintenance

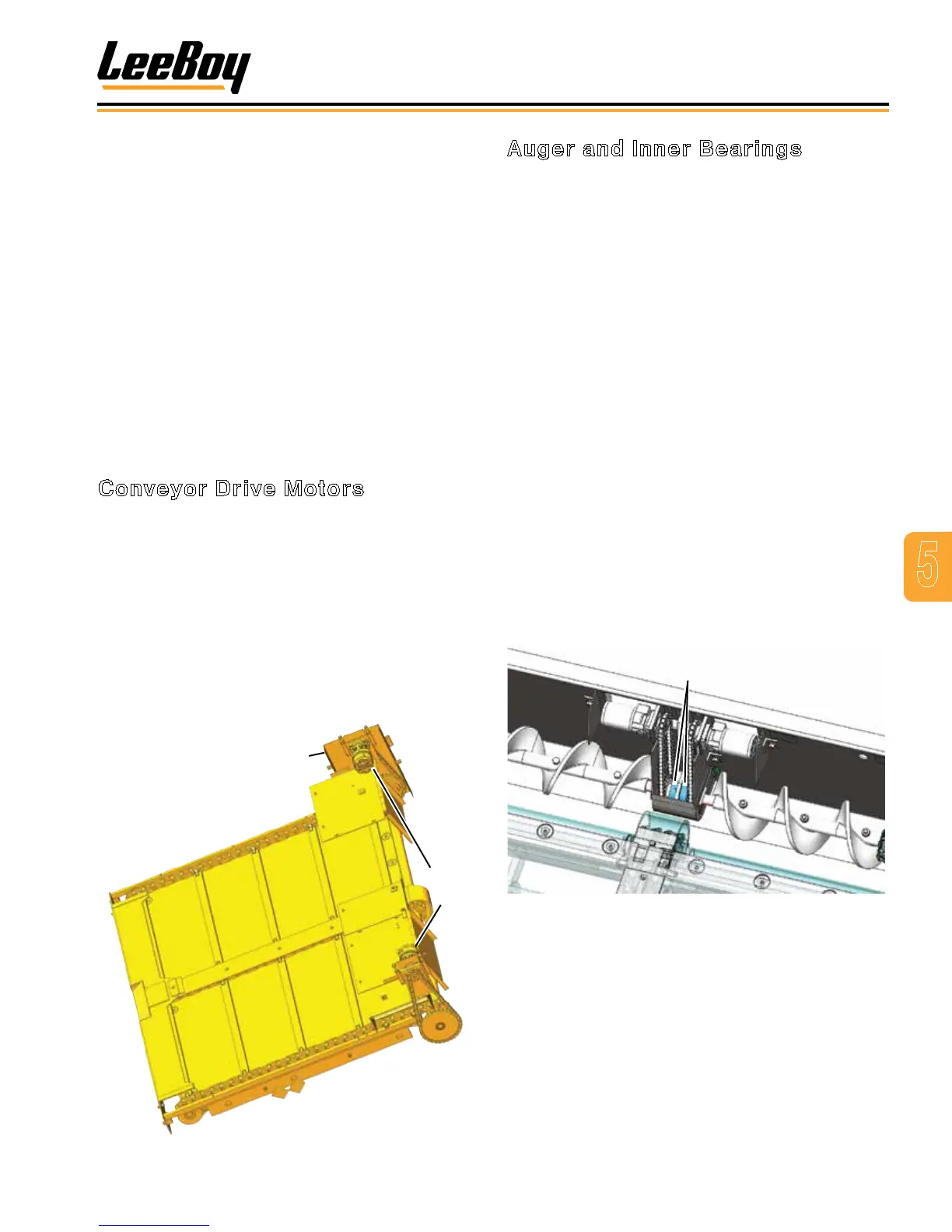

Auger and Inner Bearings

1. Remove rear grating over auger assembly.

2. Extend the screed extensions completely.

3. Clean asphalt build up from around cover.

NOTE: Heating asphalt may be required.

4. Remove the two (2) nuts holding top cover on and

pry cover apart.

5. Remove bottom portion of cover.

6. Rotate auger chains so that master link is centered

at front.

7. Loosen auger chains by sliding auger motors down

from backside after loosening the two (2) bolts

securing mounting brackets.

8. Remove bottom clamps that hold auger bearings in.

9. Remove auger end mounts so that augers can be

removed through opening in sides.

10. Remove augers and lay augers on the ground in

the same position as removed. This will help insure

proper installation of the new augers.

11. Check inner auger bearings and replace if faulty.

(Figure 5-31)

Auger Inner

Bearings

Figure 5-31. Auger Inner Bearings

NOTE: When installing the new augers, be sure to

align augers the same as the removed augers.

It is very easy to install augers backwards.

12. Install new augers making sure that they are on

correct side to auger material outward.

13. Tighten bearing setscrew to help hold auger shaft

from moving outward.

10. Place conveyor shaft into the inner conveyor

sprocket.

11. Insert bolt into shaft.

NOTE: The outer conveyor sprocket must be aligned

with the inner sprocket.

12. Rotate the outer sprocket on the shaft until properly

aligned.

13. Reinstall the outer bearing and outer sprocket.

14. Place thread-locking adhesive on the bolt and

torque to 180 ft. lbs. (244 N.m).

15. Reinstall the conveyor and drive chains and adjust.

16. Grease bearings in the tubes by using grease

blocks on each side below the hopper wing.

Conveyor Drive Motors

1. Remove hydraulic hoses from motor.

2. Remove four bolts holding hydraulic motor to slide

mount. (Figure 5-30)

3. Slide drive motor out of slide mount.

4. Slide new or repaired drive motor into slide mount.

5. Secure with four bolts.

6. Reconnect hydraulic hoses to motor.

7. Check for leaks.

Cover

Conveyor

Motors

Figure 5-30. Conveyor Motors

Loading...

Loading...