4

LeeBoy 8515D Conveyor Paver 4-3

Operation

General Information

The LeeBoy Model 8515D Conveyor Paver is equipped

with steel hydrostatic-driven tracks that propel the

paver using friction-controlled joysticks. Each track is

powered by a single-speed motor directly coupled to

torque hubs. Standard LeeBoy hydrostatic controls

provide travel direction and steering capabilities from

either side of the paver. An optional steering wheel is

also available.

The two joysticks control the speed and direction of the

paver in conjunction with the machine speed setting.

The amount of steering is controlled by the amount of

joystick movement and the speed of the paver. As the

paver speed increases, steering will be reduced.

The two conveyors are the widest in the industry to

deliver asphalt more evenly and efciently to produce

a smooth asphalt mat. Two propane burners on the

main screed and a burner on each hydraulic screed

extension provide seamless mats at paving widths up

to 15 (4.6 m) feet. Electric screed heat is an additional

option. Cut-off gates under the auger offers the

operator precise control while paving and minimizes

clean-up at the end of pulls.

Read this manual carefully before operating the

machine. Only authorized personnel who are

properly trained should operate the LeeBoy Model

8515D Conveyor Paver.

Receiving the Machine

Although the machine has been checked thoroughly by

the manufacturer, road hazards or other factors during

transport may result in damage. Be sure to check the

machine thoroughly before operating it:

1. Check engine oil. (Page 5-12)

2. Check hydraulic uid level. (Page 5-16)

3. Check machine hoses for any damage or leaks.

4. Inspect machine for any damage during transport.

Contact your authorized dealer immediately if any

damage has occurred.

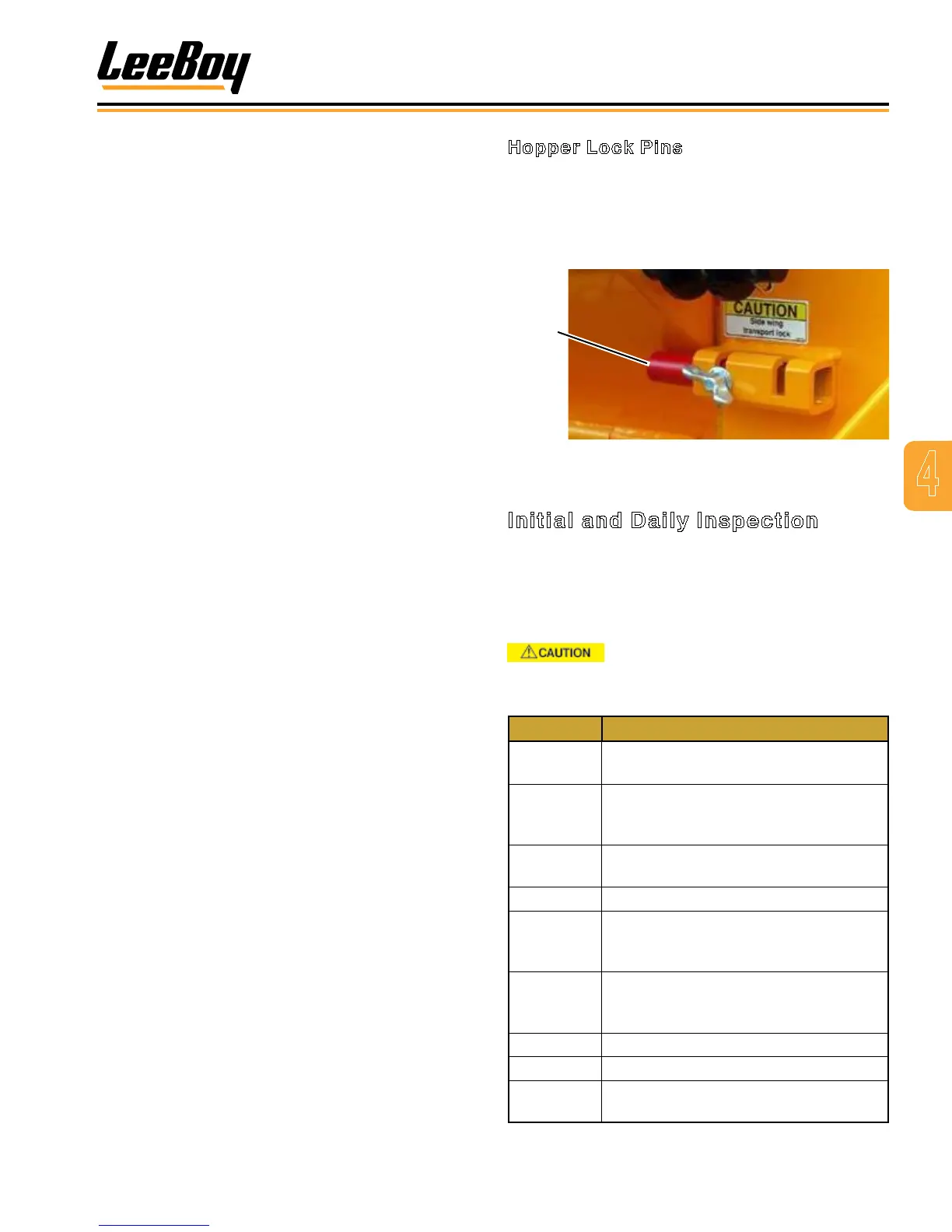

Hopper Lock Pins

This machine is provided with hopper lock pins (one

on each side). (Figure 4-1) Extend the pins to prevent

the hopper wing from inadvertently leaking down during

transport. Retract the pin and lock down the thumb

screw during operation.

Hopper

Lock

Pin

Figure 4-1. Hopper Lock Pin

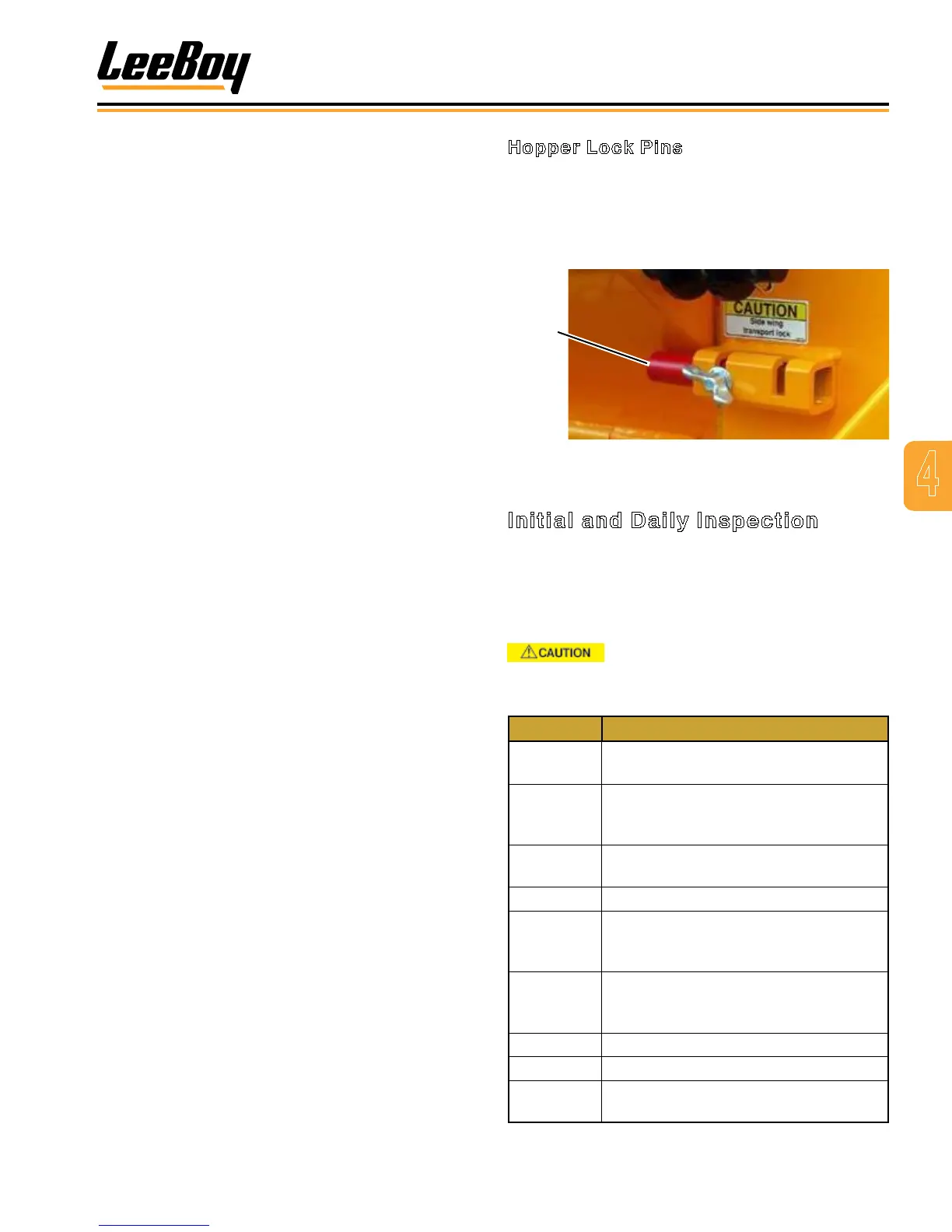

Initial and Daily Inspection

The following inspection is essential and should be

performed before the initial start-up. Visually inspect the

unit to check its general condition and for familiarization.

Continue with a check of the systems and components

shown in Table 4-1 below:

Only trained personnel should operate

the LeeBoy 8515D Conveyor Paver.

Table 4-1. Initial Inspection

INSPECT PROCEDURE

Engine Oil

Level

Maintain oil level between ADD and

FULL marks on dipstick.

Fuel Tank

Check for adequate fuel supply. Fill if

needed. Always ll tank at end of the day

to prevent condensation in the tank.

Hydraulic

Tank

Check the tank for oil level and leaks.

Radiator Check coolant level.

Battery

Ensure all cables are tight and clean.

Check for corrosion on the battery

terminals.

Air Cleaner

Check the air lter element and hose

connections. Air cleaner has both a

primary and secondary lter.

Drain Plugs Make sure plugs are inserted and tight.

Engine Belt Check for proper belt tension.

Grease

Fittings

Ensure ttings are greased and in good

working order.

Loading...

Loading...