4

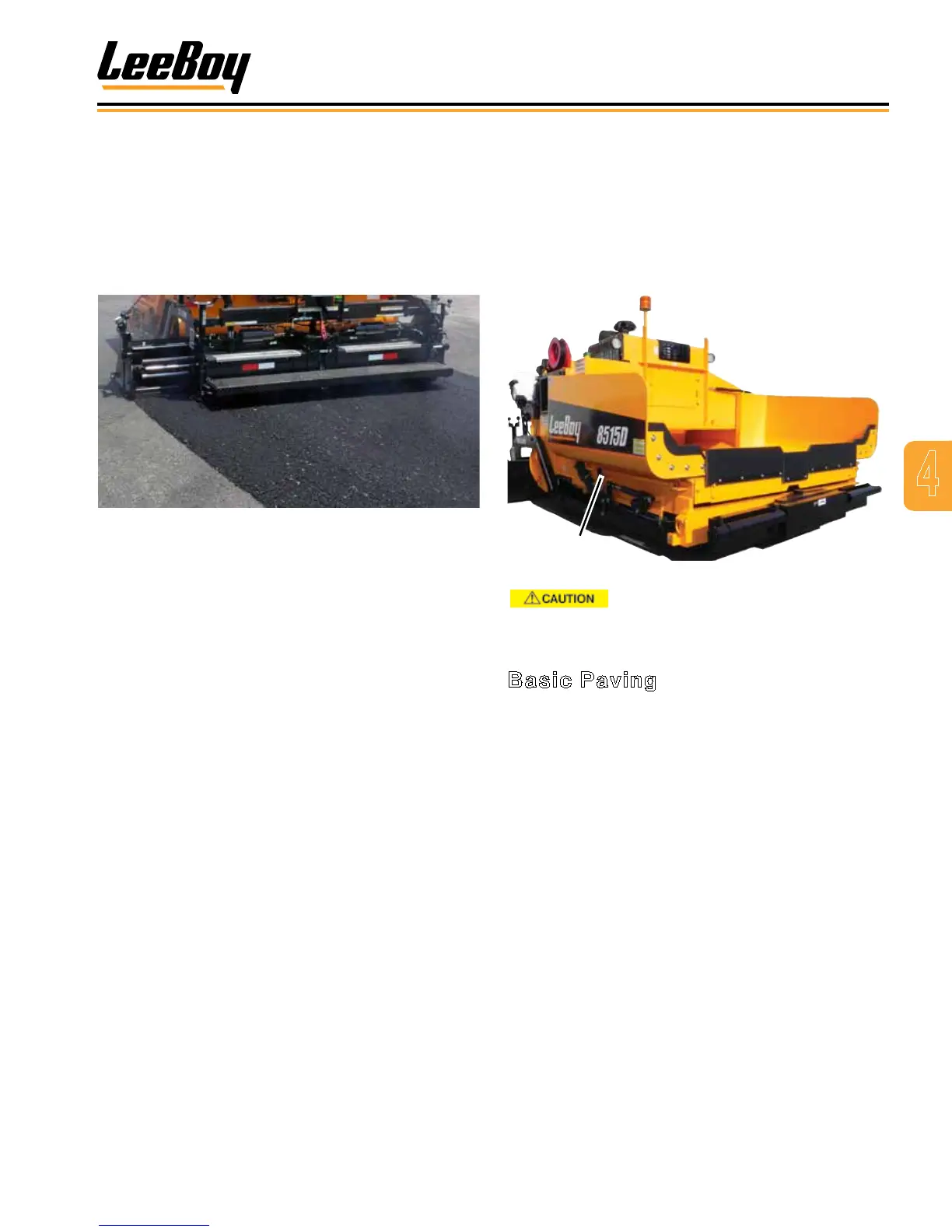

LeeBoy 8515D Conveyor Paver 4-27

Operation

• Use a reference guide such as a curb, gutter, adjacent

mat or string line.

• It is very important that the rst pass be straight as it

will serve as your guideline for the following passes.

• Extend the lower guide bar gauge to further assist you

in paving a straight line from the operator’s station.

(Page 4-50)

Guide Bar

Figure 4-50. Lower Guide Bar Gauge

Avoid low limbs, power lines, and

other objects that can endanger crew or paver.

Basic Paving

1. Position paver at the starting point for the mat.

(Operate the paver from one side only.)

2. Open cut-off gates under auger. (Page 4-23)

3. Adjust screed as needed. (Page 4-24)

4. Open hopper wings to accept asphalt from the

material truck. (Page 4-22)

NOTE: Allow only a partial load of asphalt to enter the

hopper when rst starting to pave.

6. Turn the left and right conveyor switches to the

AUTO position.

7. When the material begins to discharge from under

the screed, set the screed lift switch to the FLOAT

position. (Pages 3-6 to 3-11)

8. If paving a width more than eight feet, turn the left

and right auger switches to AUTO to control the

material height at the endgate. (Augers aren’t

needed when paving a basic eight-foot pull.)

(Pages 3-6 to 3-11)

Starting to Pave

The LeeBoy 8515D Conveyor Paver provides superior

paving for driveways, small to large parking lots, and

secondary roads. The paver is equipped with electric

and manual thickness controls, and can be operated

from either side of the operator platform. It has a

production rate of approximately 250 tons per hour.

Figure 4-49. Paving

This paver is capable of placing a mat thickness of six

inches (20 centimeters) for:

• Bituminous base.

• Binder or surface course.

• Lime or Portland cement-stabilized sub-base.

• Graded aggregate materials.

Operators should be trained to operate the various

machine components along with proper paving

techniques before operating the machine.

Before starting to pave, keep these items in mind:

• Plan the project so you pave the most narrow passes

rst (the width of the paver), leaving the widest passes

until last.

• Always pave in low range.

• It is the operator’s job to guide the material truck

back to the hopper and signal the driver when to stop

dumping the asphalt into the hopper. The driver must

maintain a light pressure on the brakes to prevent the

truck from dumping asphalt onto the ground.

NOTE: If paver is equipped with the optional truck

hitch, the truck driver will not be required to

maintain brake pressure. (Page 4-33)

Loading...

Loading...