4

LeeBoy 8515D Conveyor Paver 4-23

Operation

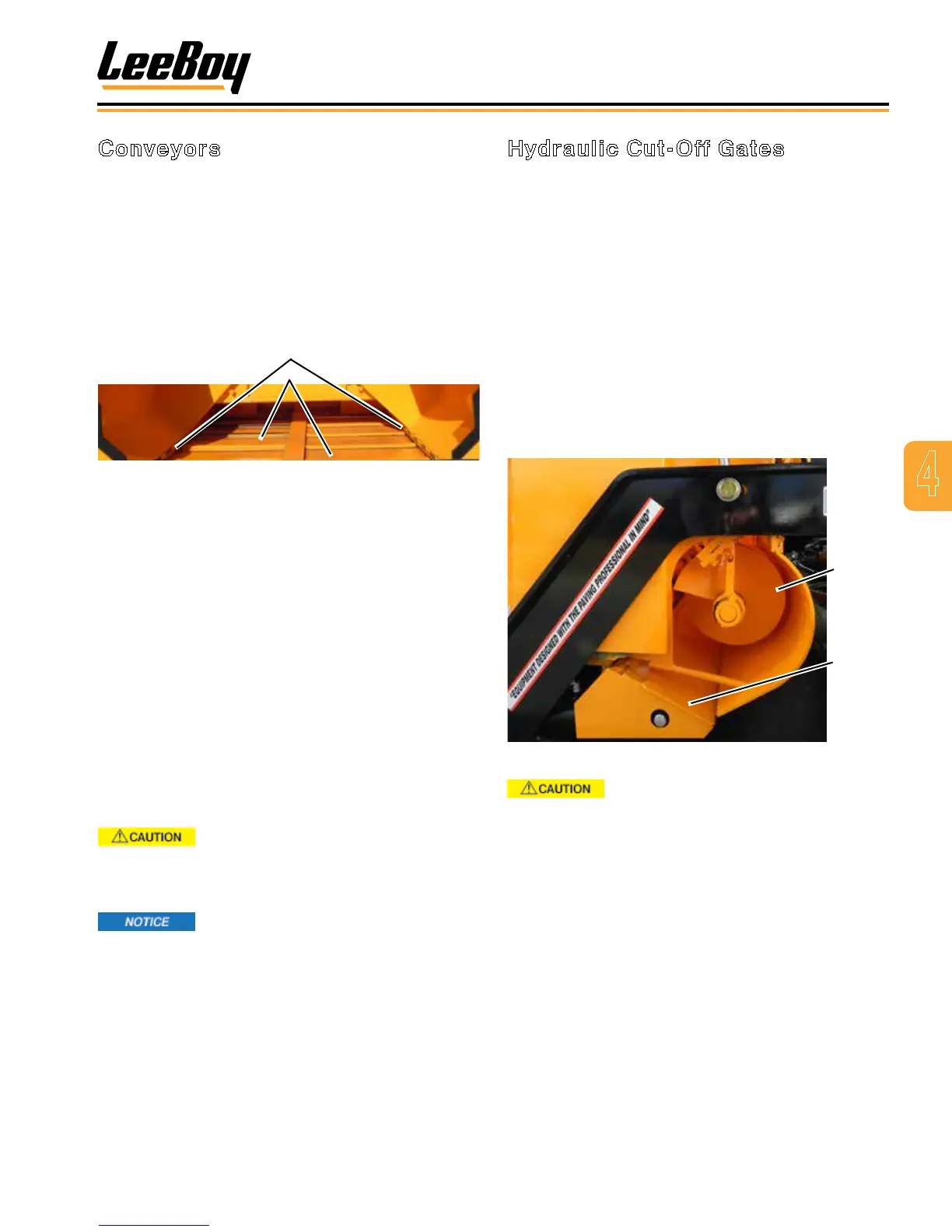

Hydraulic Cut-Off Gates

The cut-off gates are another important function of the

paver. The cut-off gates are used primarily to control

the ow of asphalt to the screed and hydraulic screed

extensions. Cut-offs can be used to limit material ow

when making narrow passes at the beginning and

ending of each pass or pull. Proper use of the cut-off

gates minimizes clean-up at the end of pulls. (Figure

4-40)

• The right and left cut-off switches on the manifold

open and close the cut-off gates.

• Holding the switch in the OPEN positions increases

asphalt ow to the screed. Holding the switch in

the CLOSED position decreases asphalt ow to the

screed.

Auger

Cut-O

Gate

Figure 4-40. Cut-Off Gate

NEVER backup with the cut-off gates

open. The cut-off gates are designed to break away

from cylinders when hitting a manhole or other

object when moving forward, but not in reverse.

Conveyors

The LeeBoy Model 8515D Conveyor Paver is equipped

with two automatic conveyors that deliver asphalt evenly

to produce a smooth asphalt mat. (Figure 4-39)

The conveyor is a very important part of the paver that

moves material from the hopper back to the auger

and out of the cut-off gates to the screed. Pay close

attention to integrating its operation into the total

operation of the paver.

1

2

Figure 4-39. Conveyor Chains and Paddles

When operating the conveyor:

• Spray down the conveyor drive chains with cleaning

solvent or release agent several times during the work

day for optimum performance.

• Select AUTO or MANUAL mode for the left or right

(or both) conveyor switch(es) on the control panel.

(Pages 3-6 to 3-11)

• If the conveyors are running while the cut-off gates are

closed, there will be spillage, which is normal. To help

prevent this spillage, work conveyors manually when

loading hopper and not paving.

• Irregular movement of the conveyor indicates that the

conveyor chains need adjustment. (See Section 5)

NOTE: Check conveyor chain adjustment every 100

hours.

Never leave the paver unattended

while the conveyor is operating. Do not leave paver

running with conveyors set to AUTO for any length of

time to prevent hydraulic oil overheating.

Asphalt in the conveyors can ll

tracks and cause damage to the machine.To prevent

ight chains from sticking inside the conveyor

pans, lubricate them daily for maximum operational

efciency.

Loading...

Loading...