4

LeeBoy 8515D Conveyor Paver 4-31

Operation

Loading

To prevent damage to the

undercarriage and throughout the paver, reduce

traveling speed before the paver tracks come into

contact with loading ramps or any abrupt change

in the surface. The track drive sprocket or other

components can be damaged by excessive shock.

The paver must be loaded screed-end

rst to prevent damage.

1. Move paver to base of ramp. Line up tracks with the

ramp.

2. BEFORE moving the machine, ensure:

• The screed position is UP.

• Auger extensions are removed.

• The extendible screed is IN.

• The cut-off gates below the augers are

CLOSED.

3. Load the paver screed-end rst. Set throttle at half

the operating RPMs.

4. Set steering control lever so paver moves very

slowly onto the ramp.

5. Using the steering control joysticks, SLOWLY guide

paver up the ramp.

6. Position paver in center of trailer.

7. Lower the screed.

8. Shut down the engine.

9. Secure paver to transport using the following tie-

down procedures.

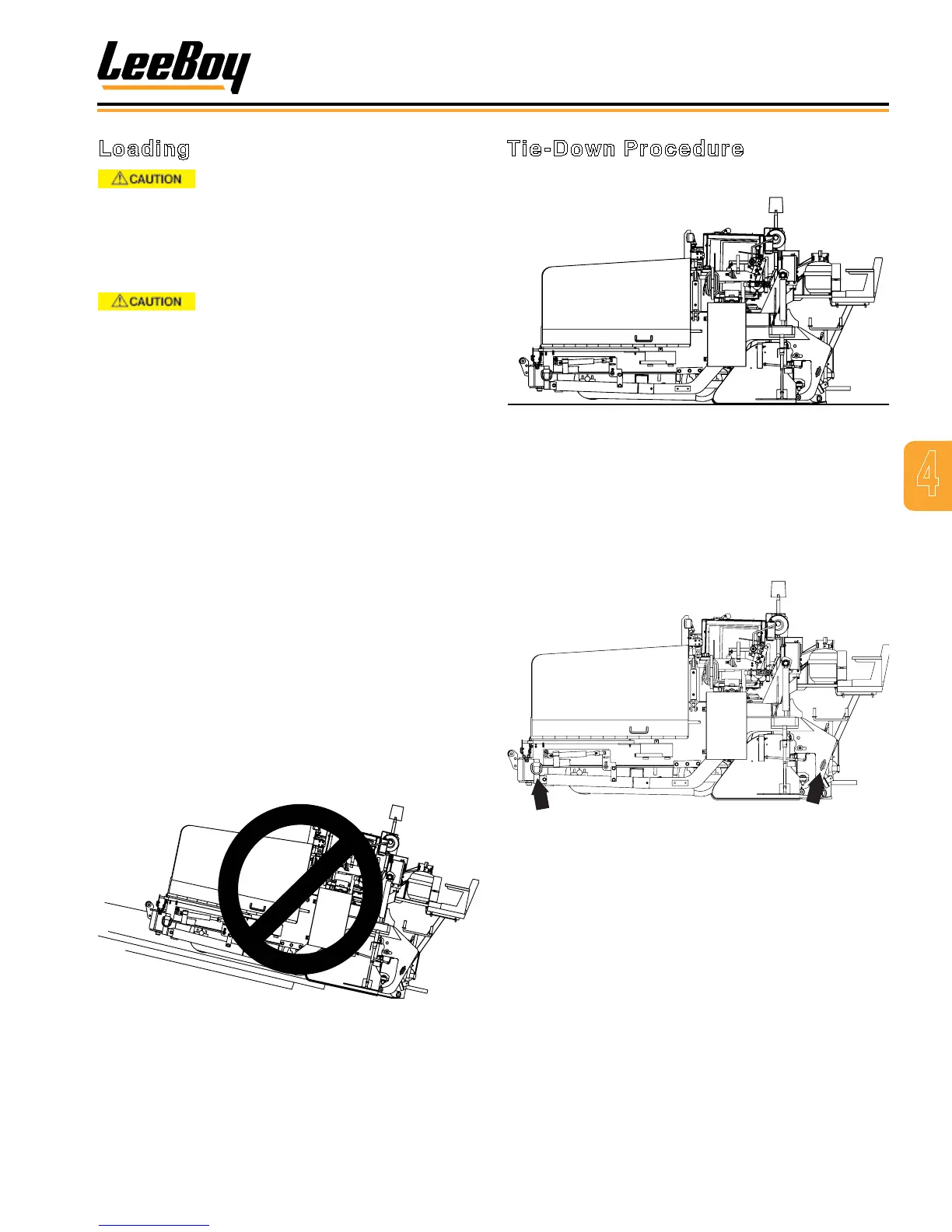

Figure 4-57. Incorrect Loading Position

Tie-Down Procedure

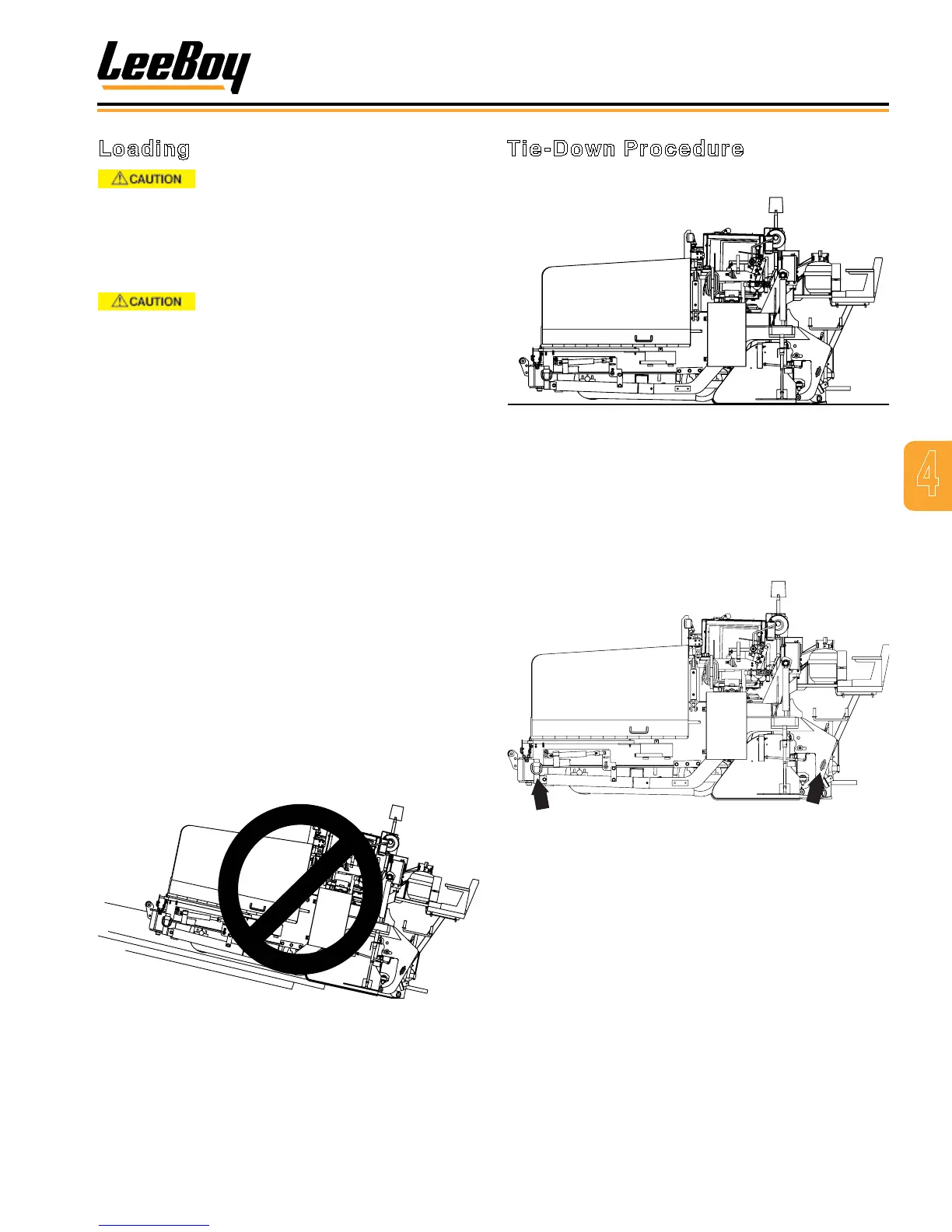

1. Position paver in center of the trailer. (Figure 4-58)

Figure 4-58. Paver on Transport

2. Attach tie-down chains to the front weight block

and the D-Rings in front of the torque hubs. (Figure

4-59).

3. Place chocks at wheels or tracks.

4. Ensure that all chains are tightly secured before

transporting the paver.

Figure 4-59. Tie-Down D-Ring Locations

Loading...

Loading...