55

LeeBoy Model 8515D Conveyor Paver 5-7

Maintenance

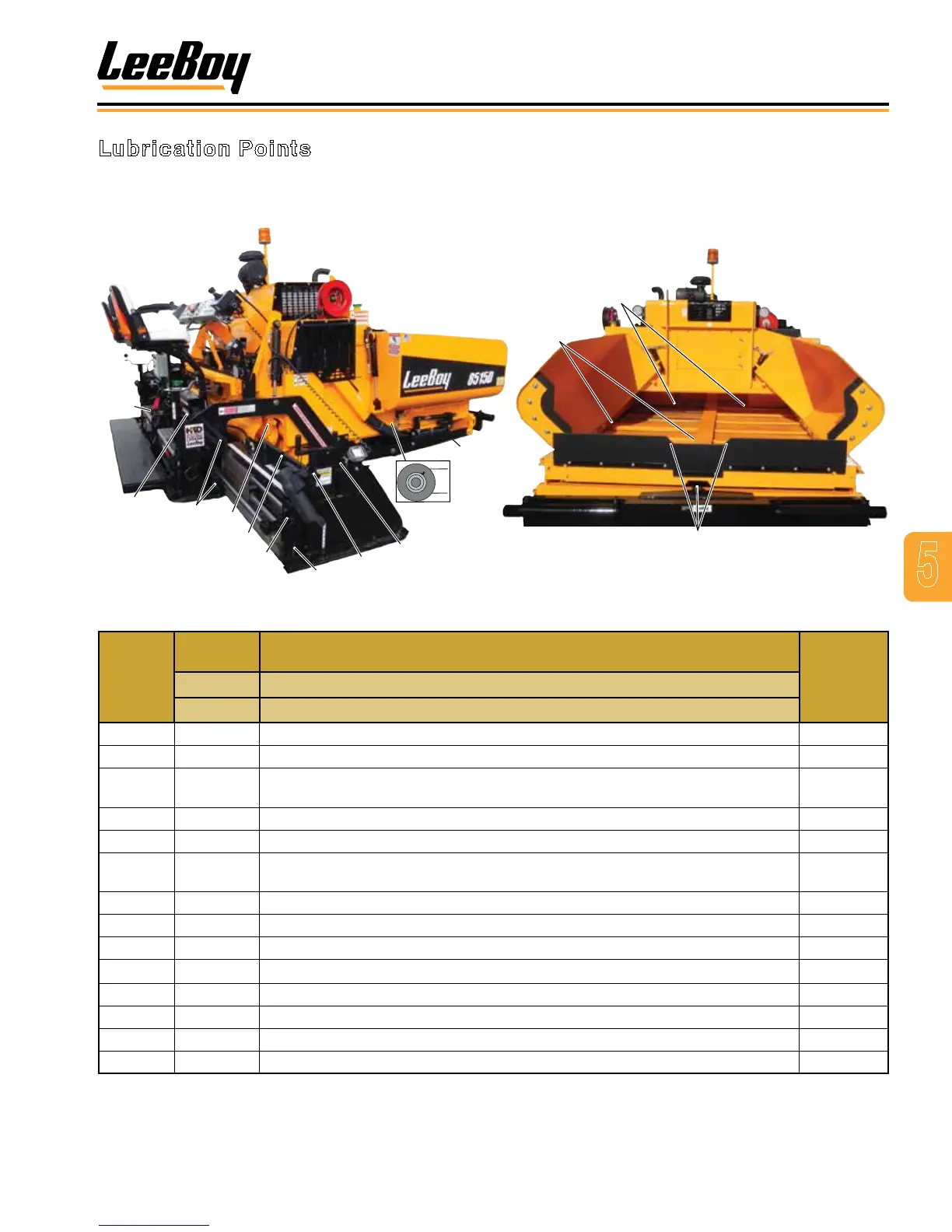

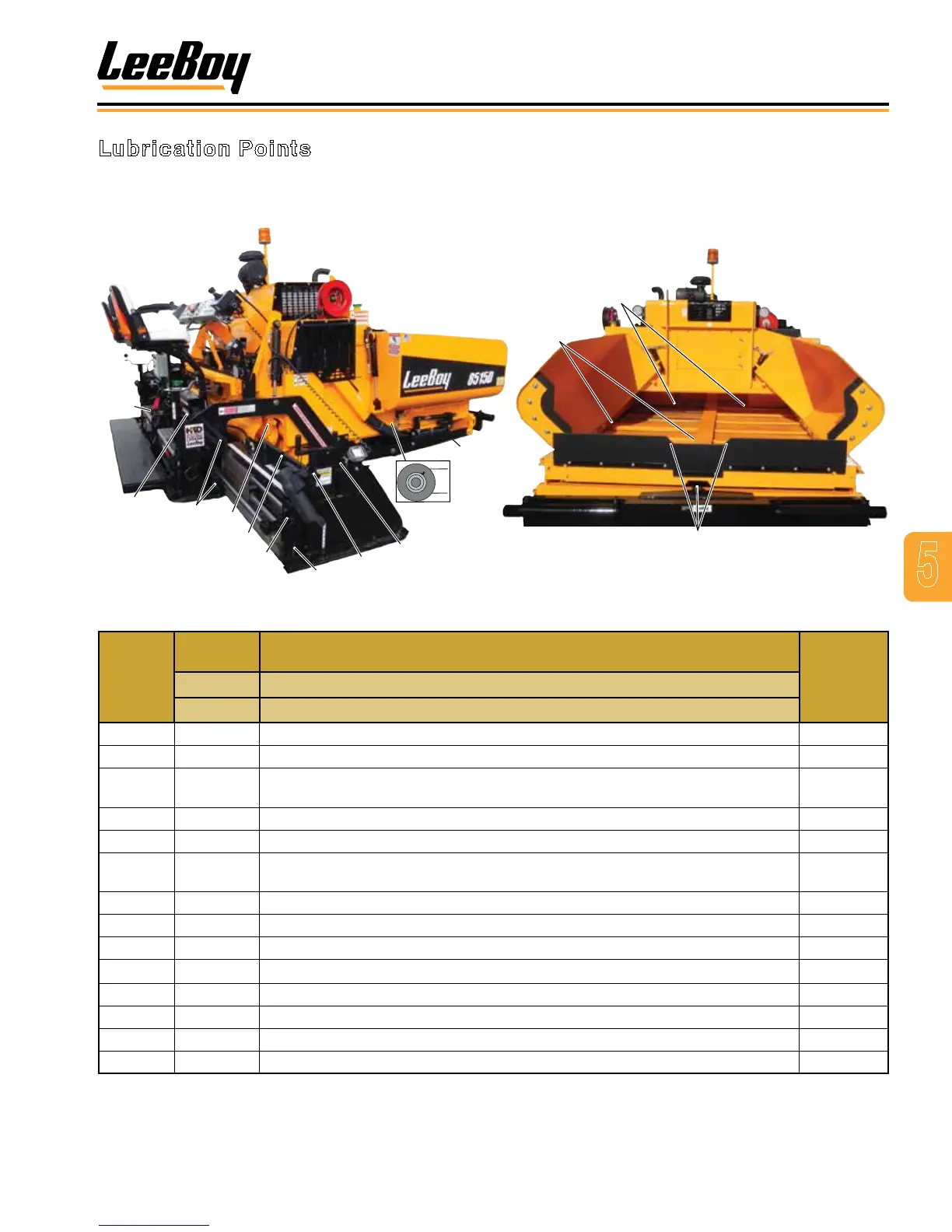

Lubrication Points

Proper lubrication is necessary to maintain the LeeBoy Model 8515D Conveyor Paver at top efciency. Refer to the

lubrication information below:

(Under Conveyor Deck)

1

2

3

4

5

6

7

8

9

10

11

6

12

13

14

Table 5-1. Lubrication Points Schedule

ITEM

NO.

TYPE

LUBE

DESCRIPTION AND LOCATION

INTERVAL

A Grease With Shell Avania EP Grease 2 or Equivalent

B Spray with Release or Chain Lube Agent

1 B Screed crown on chain. Weekly

2 A Slope cylinder pivot. Weekly

3 A

Flange bearing and tting on ight screw and ange bearing on T-handle of extensions

(both sides).

Weekly

4 A Auger. Grease tting on end mount daily for efcient operation (both sides). Daily

5 A Tilt screws (both sides). Weekly

6 A

Depth screw (both sides). Grease rst in locked position, unlock, and turn 180° to

grease.

Weekly

7 A Screed pivot. Weekly

8 A Main ight screws ball socket and nut. Weekly

9 A All screws and bearings on screed extensions (both sides). Weekly

10 A

Conveyor pivot (under conveyor deck) on front of screed (both sides). Monthly

11 B Grease tracks between track pads daily for efcient operation. Daily

12 B Conveyor chains. Daily

13 B Auger (and auger chains). Daily

14 B Spray all parts of paver that come into contact with asphalt. Daily

Loading...

Loading...