55

LeeBoy Model 8515D Conveyor Paver 5-3

Maintenance

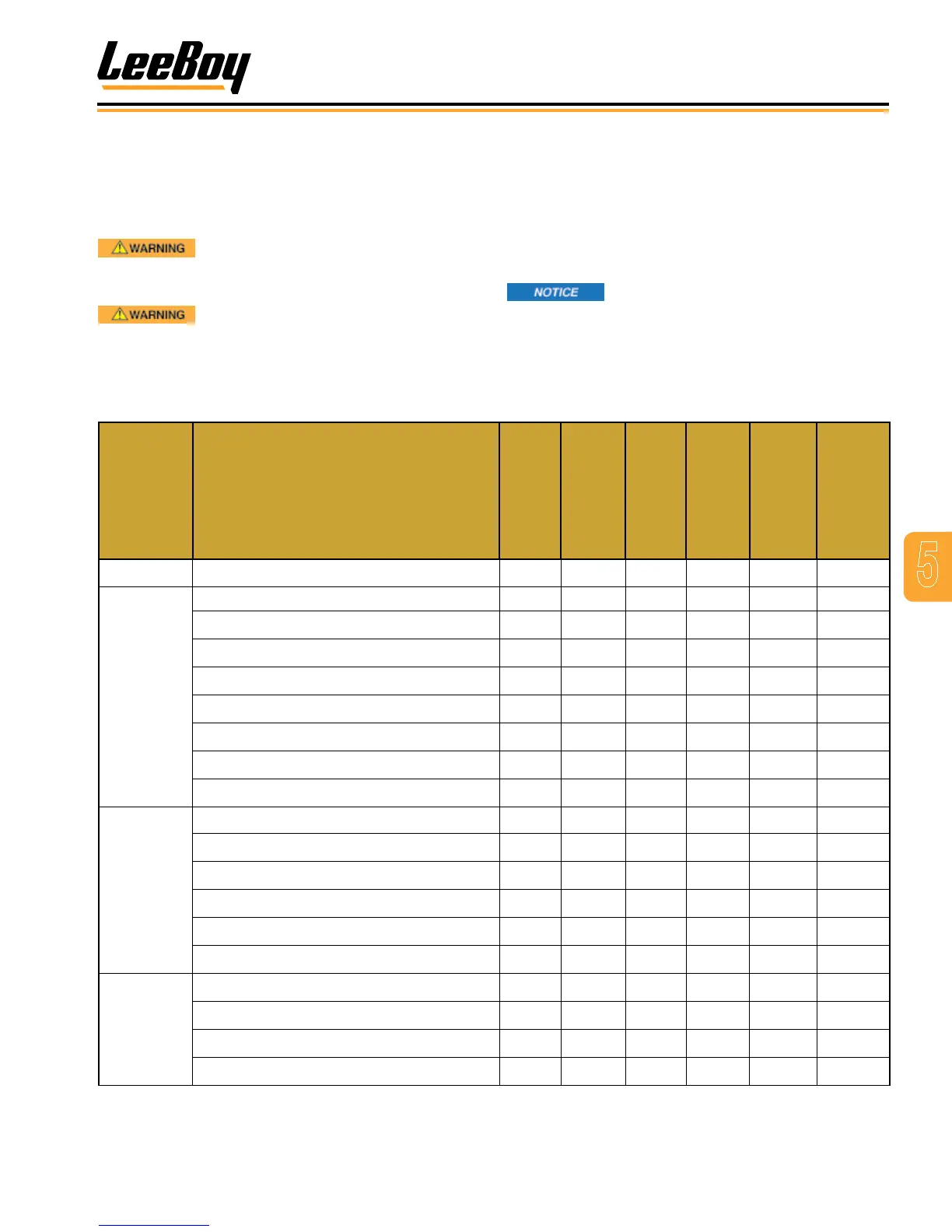

Table 5-1. Periodic Maintenance Schedule

SYSTEM ITEM

Every 10 Hours

Daily

Every 50 Hours

Weekly

Every 100 Hours

Monthly

Every 250 Hours

Quarterly

Every 500 Hours

Semi-Annually

Every 1000

Hours Annually

Paver Lubricate paver. X

Engine

Check oil level. X

Check coolant level. X

Replace coolant. X

Check air lter. X

Change air lters. X

Replace fuel lter. X

Change oil and oil lter. (Initial 50 Hours) X

Check main engine belt. X

Hydraulic

Check hydraulic oil level. X

Change hydraulic oil. X

Change hydraulic lter. X

Check torque hub oil. X

Change torque hub oil. X

Drain hydraulic tank. Replace strainer. X

Mechanical

Adjust conveyor drive chains. X

Adjust conveyor ight chains. X

Adjust auger chains. X

Adjust screed extension top guide. X

will maintain the paver in top operating condition and

provide years of trouble-free operation. Refer to the

Engine Operator’s Manual accompanying your paver for

more detailed engine service information.

When performing any routine maintenance, always

include the previous routine maintenance hours in the

higher hourly schedule.

Changing oil and cleaning the paver

should only be done in a designated area where

the oil and chemicals can be contained. These by-

products should be discarded in accordance with

environmental regulations.

Maintenance Schedule

Before performing any maintenance procedures on the

LeeBoy Model 8515D Conveyor Paver, review the safety

information in Section 1.

Always use the appropriate and

correct sized tools for the task at hand to prevent

damage or possible injury.

Always wear heat-resistant gloves

when handling hot components.

Following the maintenance schedules and procedures

Loading...

Loading...