55

LeeBoy Model 8515D Conveyor Paver 5-31

Maintenance

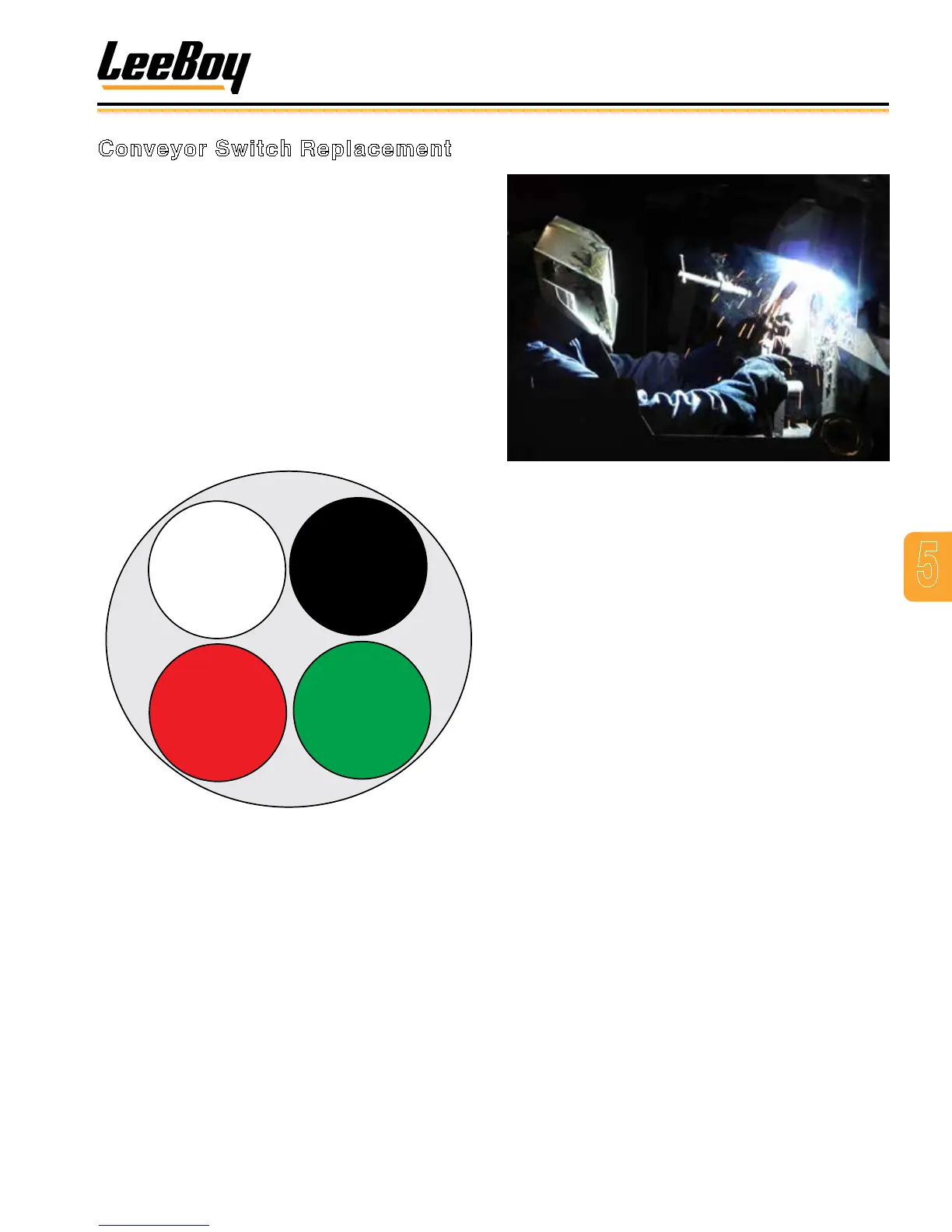

Weldment

Figure 5-39. Welding

If the machine has been damaged or metal parts worn

due to extensive use, minor welding may be necessary

for repair. Welding is very dangerous. Only individuals

who are properly trained should weld in a dedicated

area away from others as even looking at ultraviolet light

from the ame can cause serious eye injury.

Welding hazards include toxic fumes, harmful dust,

light radiation, burns, combustion from sparks and the

potential for extensive damage to the eye. There is also

a danger of electric shock. If combustible or ammable

materials are nearby, the heat and sparks produced by

welding can cause res or explosions.

TURN THE BATTERY SWITCH OFF AND

DISCONNECT BATTERY TERMINALS BEFORE

WELDING ON THE MACHINE.

Electrical current can ignite re or cause an explosion,

therefore it is critical to turn off power to the machine. It

is also important to grind off the paint to ensure proper

ground on the area being welded.

DO NOT MAKE MODIFICATIONS TO THE MACHINE.

ONLY weld if needed for repair purposes. Weldment

modications to the machine can void your warranty.

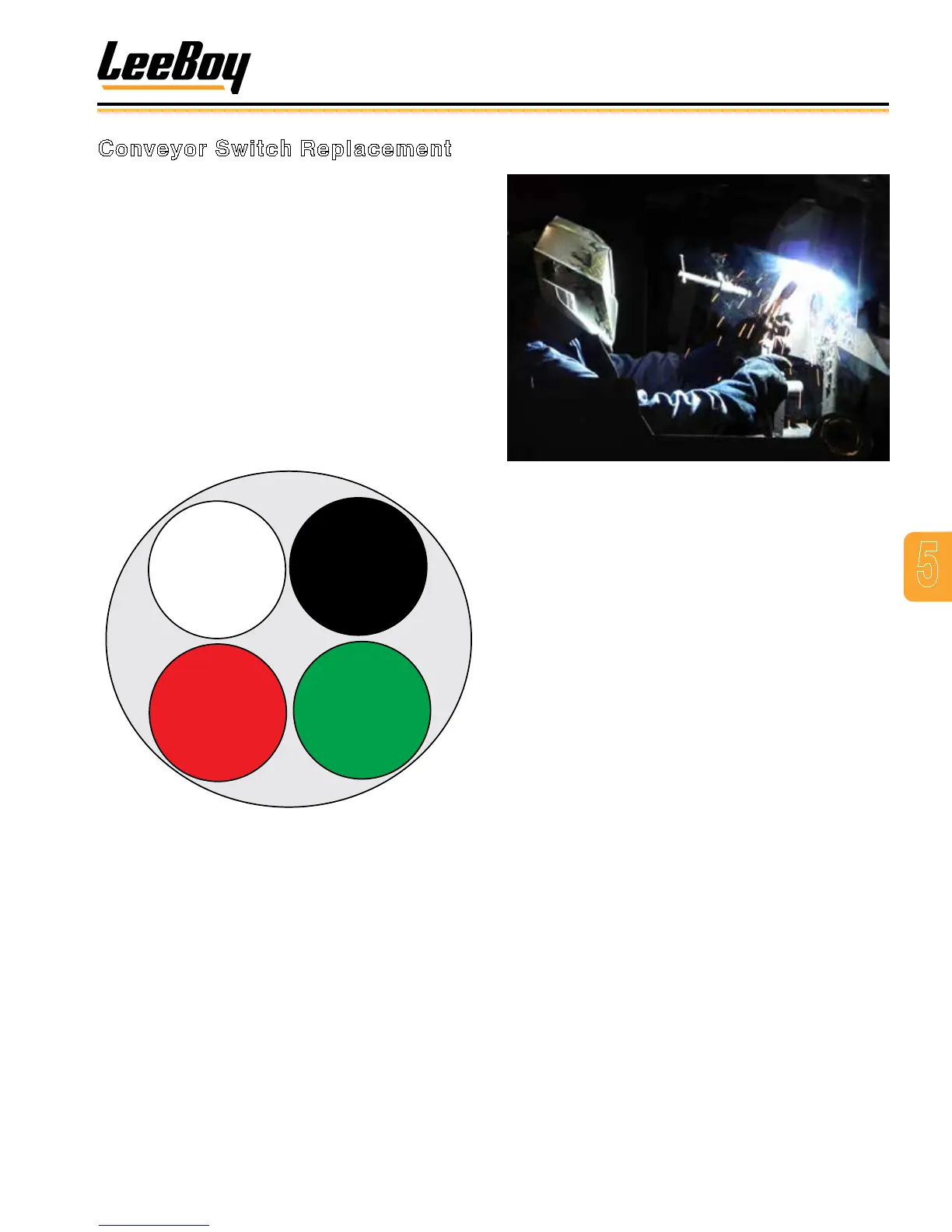

Conveyor Switch Replacement

If you need to replace the conveyor switches, follow

these instructions, using the color codes for wiring

(Figure 5-38) to ensure the conveyor switches on the

conveyor ap are wired correctly:

1. Raise the conveyor ap 6-1/2 to 7 inches (16.5 to

17.8 cm) from the bottom of the tank mount support.

2. With the switch installed and the conveyor paddle

hanging down:

• Using a multimeter, measure the ohms across

the black and white wires.

• Using a multimeter, measure the ohms across

the red and green wires.

4

WHITE

3

BLACK

1

RED

2

GREEN

Figure 5-38. Conveyor Switch Wiring

3. Wire the switch using the wires that show continuity.

4. Repeat Steps 2 - 3 for the second switch.

NOTE: The switches are sealed and potted,

therefore, they are not serviceable.

Loading...

Loading...