5-6 LeeBoy Model 8515D Conveyor Paver

Maintenance

Every 1000 Hours or Annual

Routine Maintenance

1. Drain hydraulic tank and replace strainer.

2. Replace air lter. (Page 5-13)

3. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Lubrication

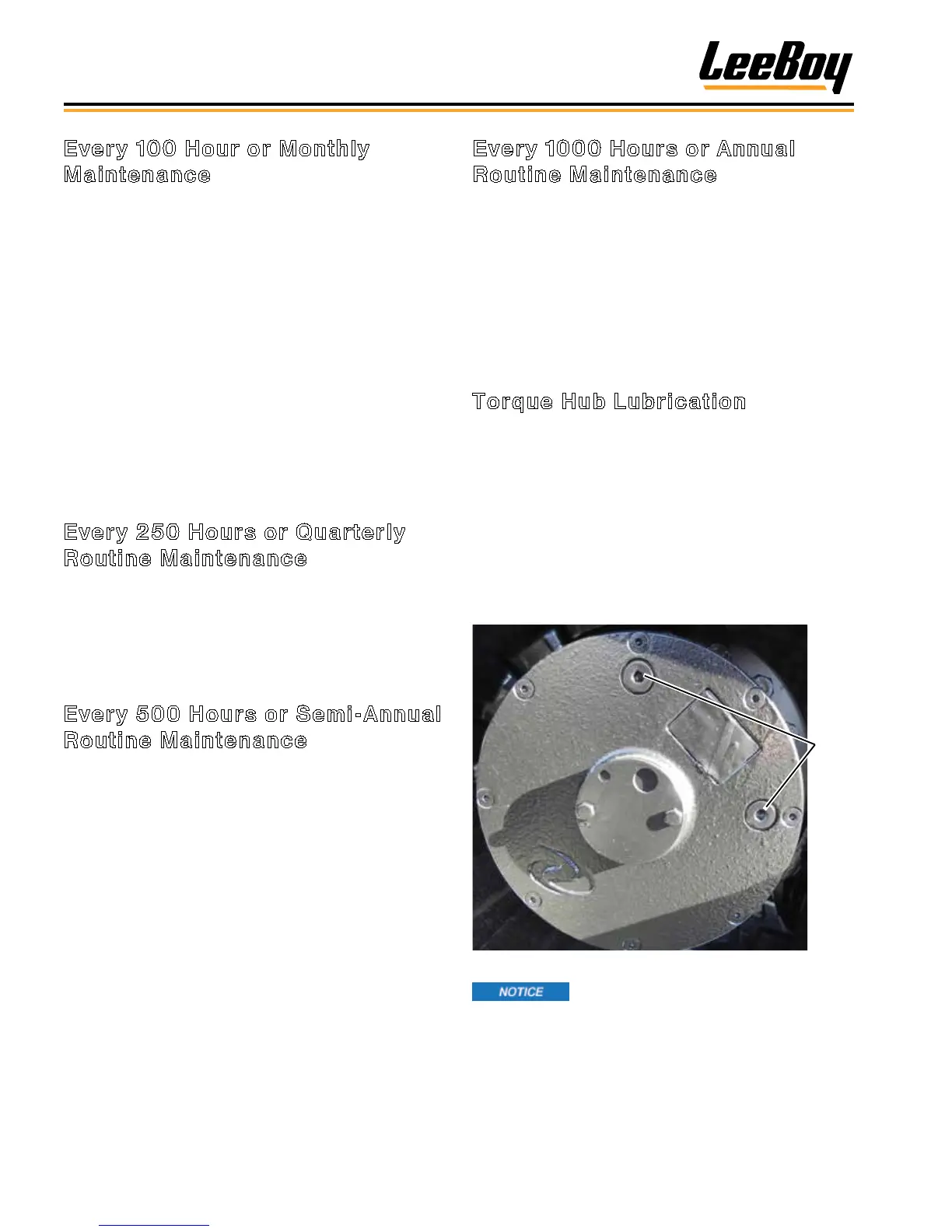

Torque Hub Lubrication

1. Remove the plug in the 3 o’clock position. (Figure

5-5)

2. If oil comes out, no oil is needed. Reinsert the plug

and tighten.

3. If oil does not come out, remove the top plug and ll

with SAE 90 WT gear oil until oil starts to appear at

the 3 o’clock plug.

4. Replace both plugs and repeat process on the

other torque hub.

Plugs

Figure 5-5. Torque Hub Plugs

Changing oil and cleaning the paver

should only be done in a designated area where the

oil and chemicals can be contained. DIscard these

by-products in accordance with environmental

regulations.

Every 100 Hour or Monthly

Maintenance

1. Check main engine belt. Adjust or replace if

needed.

2. Check and adjust conveyor drive chains. (Page

5-8)

3. Check and adjust conveyor ight chains. (Page

5-8)

4. Check auger drive chains, lubricate and adjust.

(Page 5-9)

5. Check and adjust screed extension top guide.

(Page 5-9)

6. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Every 250 Hours or Quarterly

Routine Maintenance

1. Clean air lter.

2. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Every 500 Hours or Semi-Annual

Routine Maintenance

1. Replace coolant.

2. Change engine oil and lter. (Page 5-13)

3. Change air lter and replace if needed. (Page 5-13)

4. Change torque hub oil.

5. Replace fuel lter. (Page 5-14)

6. Clean water separator. (Page 5-15)

7. Change the hydraulic oil and lter. (Page 5-16)

8. Perform previous routine maintenance and any

other engine preventive maintenance described in

the Engine Operator’s Manual.

Loading...

Loading...