55

LeeBoy Model 8515D Conveyor Paver 5-11

Maintenance

5. Repeat procedure for the lower ap.

If the lower ap switch did not click OFF:

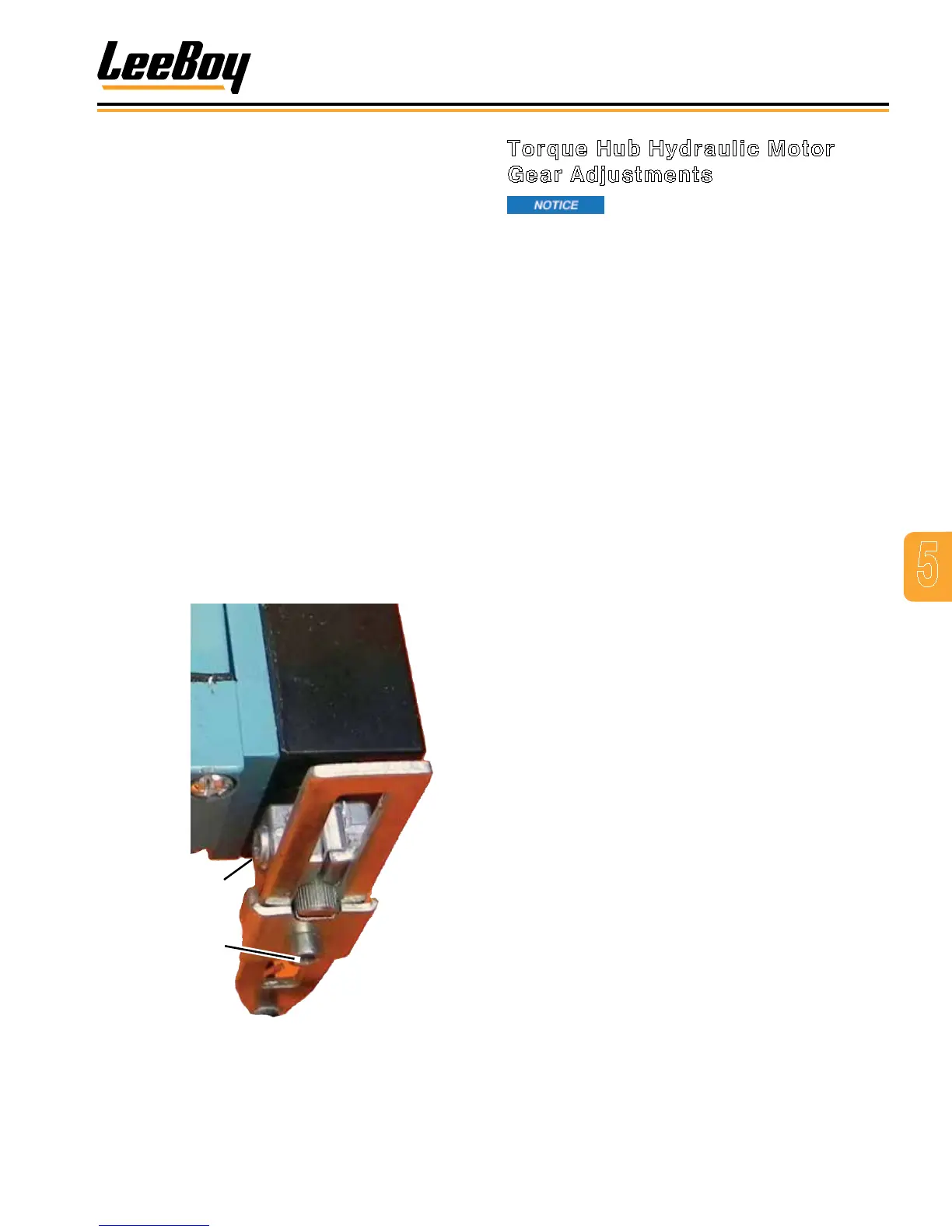

1. Loosen Setscrew B. (Figure 5-12)

2. Slide the actuator arm IN or OUT bo bring the travel

limits into tolerance.

3. This may require several adjustments before the

correct position is obtained.

4. When the actuator arm is in the correct position,

tighten Setscrew B.

NOTE: The factory setting is one inch (2.54 cm) from

the center of Setscrew B to the eyelet on the

actuator arm.

NOTE: The setting from the factory is 1 in. (2.54 cm) from

the center of the setscrew “B” to the eyelet on

the actuator arm.

5. To bring the travel limits into tolerance, slide the

actuator arm in the direction desired. This may

require several adjustments before the correct

position is obtained. When the actuator arm is in the

correct position, tighten setscrew “B”. No further

adjustment is necessary.

Setscrew A

Setscrew B

Figure 5-12. Actuator Arm - Setscrews A and B

Torque Hub Hydraulic Motor

Gear Adjustments

Torque hub hydraulic motors are

calibrated and set at the factory. These adjustment

should only be performed by an authorized LeeBoy

dealer. Work not performed by an authorized dealer

can damage machine and void the warranty.

The low gear adjustment must be made to the slow

side drive motor only. The low gear adjustment screw

is located on the bottom of the drive motor. Make only

small adjustments at a time.

Your authorized LeeBoy dealer will perform the tracking

adjustment on the high side gear by adjusting the screw

on the top of the hydraulic motor. This adjustment on the

motor for the fast track must be screwed in to equalize

track speed.

Your LeeBoy dealer will perform the following

procedure to adjust either gear:

1. With paver running, push the 2-Speed switch:

• Set both 2-Speed switches on both sides of the

control panel to the LOW position if adjusting

low gear. (The red 2-Speed light should not

illuminate.)

• Set either 2-Speed switch to the HIGH position

if adjusting high gear. (The red 2-Speed light

will illuminate.)

2. Adjust screw (on bottom of the hydraulic motor for

low gear; on top for high gear) until you feel back

pressure on the adjustment screw. This indicates

the correct adjustment is close.

3. Finalize adjustment by making a one-quarter

(1/4) turn at a time until the correct adjustment is

accomplished. Recheck tracking.

NOTE: If hydraulic motor has not been previously

set, ten revolutions of the adjustment screw may be

required before noticing any difference in travel.

Loading...

Loading...