4-34 LeeBoy 8515D Conveyor Paver

Operation

815HD (Heavy Duty) Electric

Screed

The optional 815 HD screed is sturdier, heavier and

easier to rebuild. This enhanced screed option can

include power crown, ight screws and electric heating

system (with ve heating elements on the main screed

and one on each hydraulic extension). The sonic auger

mount has adjustable positions. The 815 HD screed

offers two options within this option for even more

robust screed operation: Heated Endgates and Heated

Edge Endgates.

Topcon® sonic grade

control, dual grade

control and slope

options offer paving

professionals screed

control for improving

smoothness along with

assuring accurate slope

and material thickness.

These controllers send

signals to the screed to

precisely maintain mat

thickness and slope as

you pave.

Topcon® Sonic and Dual Grade

Control

Figure 4-65. Sonic Grade

Control

Sonic trackers continuously measure the elevation over

the surface, automatically averaging and adjusting the

tow point cylinder on the paver. The LCD digital display

is easy to see regardless of light conditions.

Choose from one of three options: Sonic Grade Control

(one side); Dual Grade Control or Dual Grade Control

and Slope (both Topcon P-32 systems). The dual

grade controls automatically maintain a set depth on

both ends of the screed. The Dual Grade and Slope

controls maintain a set depth on one end of the screed

and as et slope to the other end.

Most states require this technology for state road paving

jobs to ensure smoothness and continuity on roadways.

Rubber or Steel Track Options

The LeeBoy 8515D paver is equipped with poly-pad

tracks. However, steel or rubber track options are

available in lieu of the poly-pad tracks.

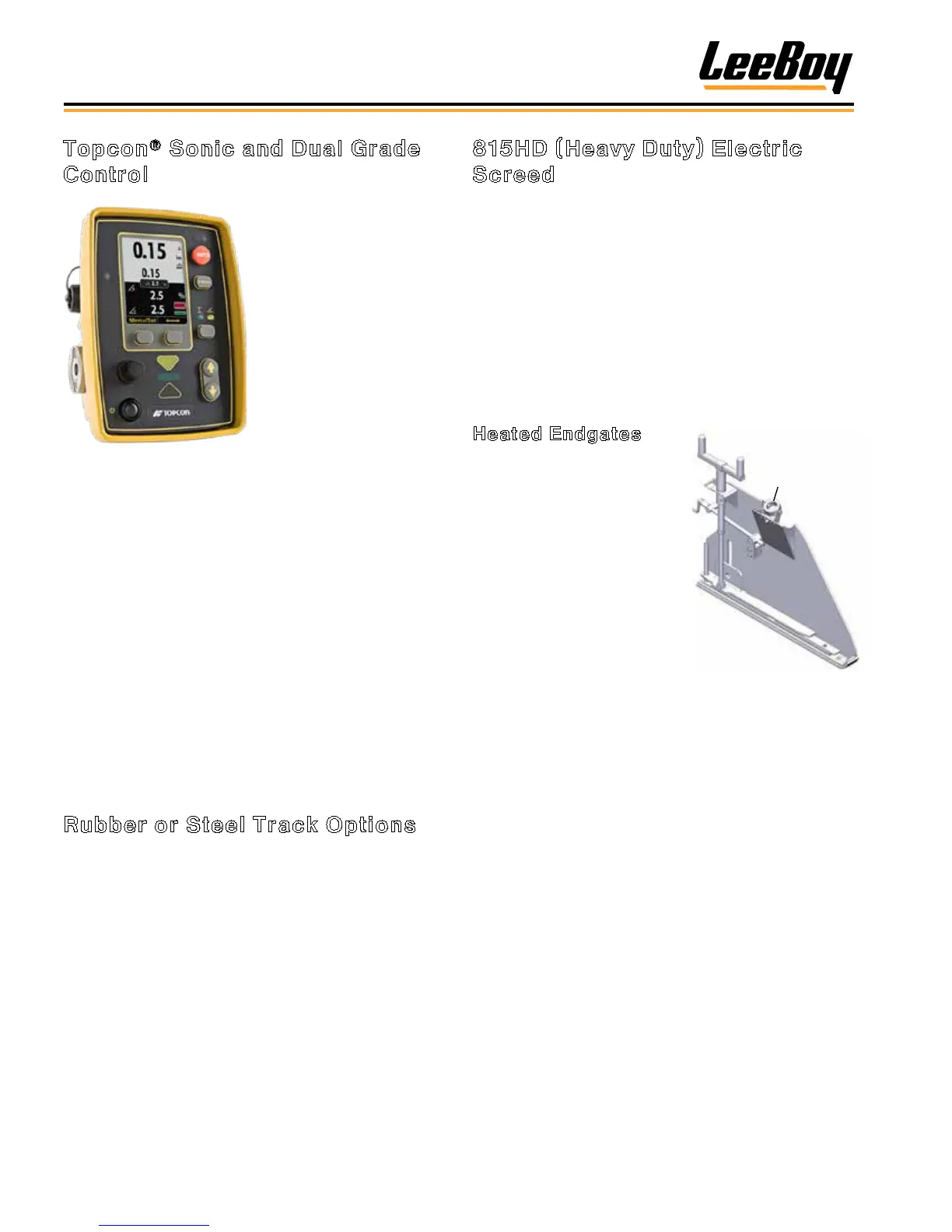

Heated Endgates

The heated endgate

also heats the edge of

the endgate, producing

a smoother joint as you

pave. (Figure 4-66)

(When the heated endgate

is turned on, the leading

heating element turns off

on the side you’re heating.)

With the heated endgate

option(s), additional

switches are added to the

electric heat control box.

Adjustable

Sonic Auger

Mount

Figure 4-66. Heated

Endgate

To operate the heated endgates:

1. Start the paver and idle until the engine reaches

normal operating temperature.

2. Raise the screed plate one or two inches off the

ground.

3. Turn the electric heat control box power ON by

turning the power switch up. (Figure 4-67)

4. Press the Start Heat button. The HEAT ON indicator

light will illuminate and stay on as long as the

element is heating (approximately 20 minutes).

5. Turn the left or right endgate switch up to the ON

position.

6. You can restart the cycle by repeating Step 4 if

needed.

Loading...

Loading...