GENERAL INFORMATION

The LeeBoy L300 and L600 Tack Distributors are

equipped with a Honda four-stroke, single-cylinder

engine (or optional Hatz diesel engine) coupled to a

Viking spur gear pump. The pump supplies pressure to

spray the asphalt through the spray wand and spray bar.

A relief valve adjusts this pressure. The system consists

of an asphalt pump, a spray wand, hoses and valves for

asphalt material delivery.

An exhaust stack at the rear of the unit directs burner

exhaust up and away from the operating area. A

discharge valve at the rear of the tank facilitates draining

tank contents.

This section details functions and procedures for

operating the distributor. Always inspect the distributor

unit before use for optimal performance. Repair or

replace any malfunctioning, broken or missing parts

promptly.

ALWAYS block the tires with wheel

chocks on both sides of the tires to prevent the unit

from moving when not hitched to the towing vehicle

or while performing maintenance.

Only authorized personnel who are

properly trained in the operation of the LeeBoy tack

distributor should operate the unit.

DO NOT operate a tack distributor

unit that needs repair or scheduled maintenance.

Make any repairs promptly and perform routine

maintenance at regular intervals. (See Section

5) Even minor damage can result in major system

failure.

DO NOT operate the burner while the

distributor is moving or in transit to the work site.

When cleaning, DO NOT spray the

electrical components with a water-jet or high-

pressure cleaner. ALWAYS wear safety glasses if

cleaning with compressed air. Use only halogen-

free, cold cleaners with a high ash point. NEVER

clean with benzene as it highly ammable and can

generate an explosive gas/air mixture.

If working at night or other low

visibility conditions, equip the unit with special

lighting. Use reective tape on all sides of the unit

and use impact barriers to protect workers from

trafc hazards. Be sure all personnel wear reective

vests when working in these conditions.

RECEIVING THE MACHINE

Although the distributor has been checked thoroughly

by the manufacturer, road hazards or other factors

during transport may result in damage. Should any

damage occur in transit, notify the shipping agent and

your LeeBoy dealer immediately.

Be sure to check the distributor thoroughly before

operating it:

• Check engine oil level.

• Check fuel level.

• Check all spraying components.

• Check for any loose components that could have

occurred in transit. Tighten if needed.

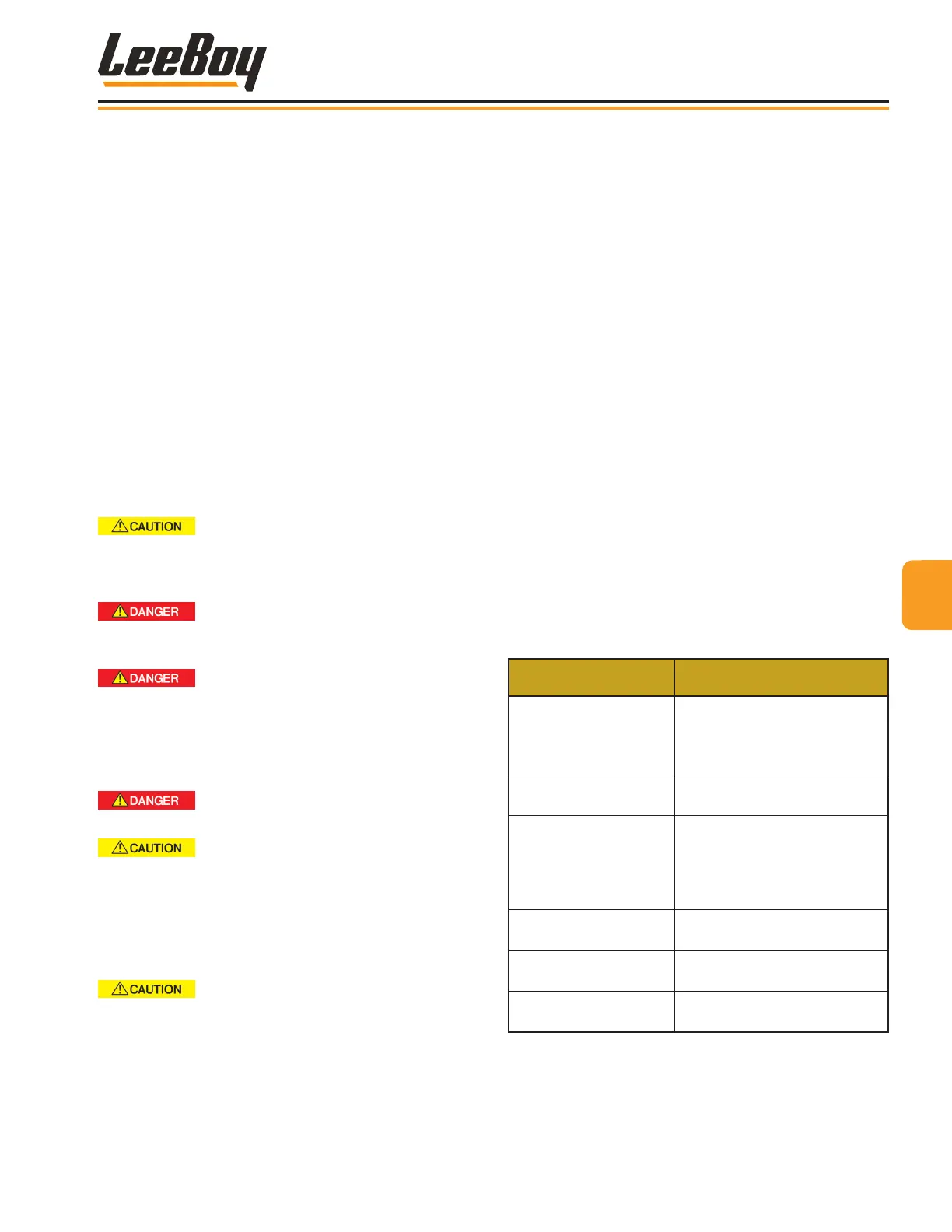

Initial and Daily InspectionInitial and Daily Inspection

The following inspection is essential and should be

performed before operating the distributor. Visually

inspect the unit to check its general condition and

for familiarization. Always check the systems and

components shown in the table below before operating

the distributor:

Table 4-1. Initial and Daily Inspection

INSPECT PROCEDURE

Hoses and Lines

Check for any leaks or crimped

hoses on all the distributor

systems. Repair or replace if

needed.

Covers and Guards

Ensure all covers and guards

are in place and free of debris.

Spray Wand

Ensure hand spray wand and

hose is connected. Ensure

spray nozzles are clean and

properly tightened. If not,

contact your dealer.

LPG Burner

Check propane gas level. Rell

propane tank if needed.

Grease Fittings

Ensure ttings are greased and

in good working order.

Spray Bar (if equipped

with this option)

Ensure spray nozzles are

clean and properly tightened.

44

Operation

L300 and L600 Tack Distributors 4-3

Loading...

Loading...