The spray bar height can be manually set in a lower or

higher position via two bolts on the bar. Reinstall the

bolts securely before spraying.

NOTE: Set the spray bar height at the lowest

position on windy days to maintain the

proper spray pattern and prevent material

waste.

To operate the spray bar:

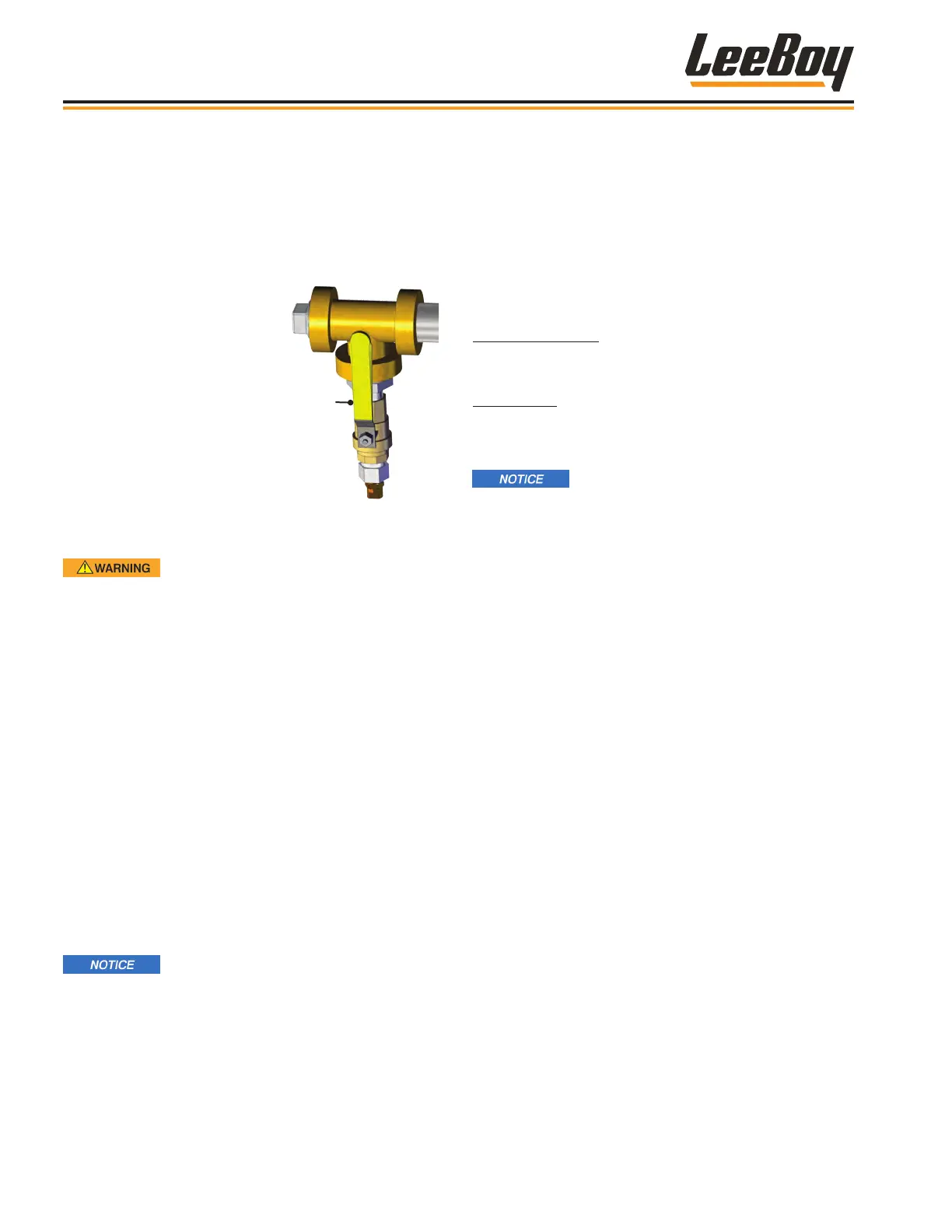

1. Align tow vehicle with the

area to be covered.

2. After determining width of

the spray pattern needed,

open each individual spray

bar nozzle valves by turning

the valve counterclockwise,

according to the width of

the area you’re covering.

(Figure 4-19)

Nozzle

Valve

Figure 4-19. Spray

Nozzle

Open the spray bar nozzle valves

BEFORE opening the spray bar valve to prevent

the lines from becoming pressurized and possibly

spraying hot tack on the operator or bystanders.

3. Ensure the spray wand, circulating, ush and

sampling valves are all CLOSED. (Figure 4-16 on

Page 4-18.)

4. Pull the selector lever DOWN to select other

operational modes.

5. Turn ON the liquid asphalt valve by turning the valve

right.

6. Open the spray bar valve by pulling the lever DOWN.

7. Slowly move tow vehicle forward along coverage

area. When nished, close the spray bar valve by

pulling the valve lever UP. (Figure 4-16 on previous

page.)

8. Perform the Reverse Suction and Back Flush

procedures described on the following pages.

When moving from one job site to

another, turn the individual nozzle valves OFF to

prevent dripping.

CLEANING THE SYSTEM

Cleaning the distributor system daily prevents asphalt

material from clogging components. Allowing tack

material to build up in the system where it will harden

will block the hoses, piping and nozzles, rendering the

distributor inoperable and requiring costly repairs.

Properly cleaning the distributor system is a two-step

process that must be performed in this order:

Reverse Suction: This procedure pulls the asphalt

material from the plumbing circuit back into the asphalt

tank.

Back Flush: This procedure circulates solvent

throughout the system to clean residual asphalt material

from components and piping, returning the used solvent

back to the ush tank for reuse or disposal.

DO NOT ush the system until you

have properly completed the Reverse Suction

procedure to remove excess asphalt material from

the system back into the asphalt tank.

Reverse SuctionReverse Suction

The Reverse Suction mode creates a vacuum that

pulls material from the distributor system and plumbing

circuit. This is an extremely important process for

proper machine operation, and should ALWAYS be

done when spraying is complete and before ushing

the system.

NOTE: If moving from one job site to another,

perform the Reverse Suction procedure

before moving to the next job site, and again

at the end of the day before ushing the

system.

To perform the Reverse Suction procedure:

1. Park the distributor on level ground.

2. Ensure the liquid asphalt valve is in the OFF position,

and the following valves are in the CLOSED position

before proceeding. (Refer to Page 3-6 and 3-7,

Valve Controls.)

• Propane tank valve.

• Pilot valve.

• Shut-Off valve.

• Burner valve.

• Sampling valve.

• Flush valve.

Operation

L300 and L600 Tack Distributors4-20

Loading...

Loading...