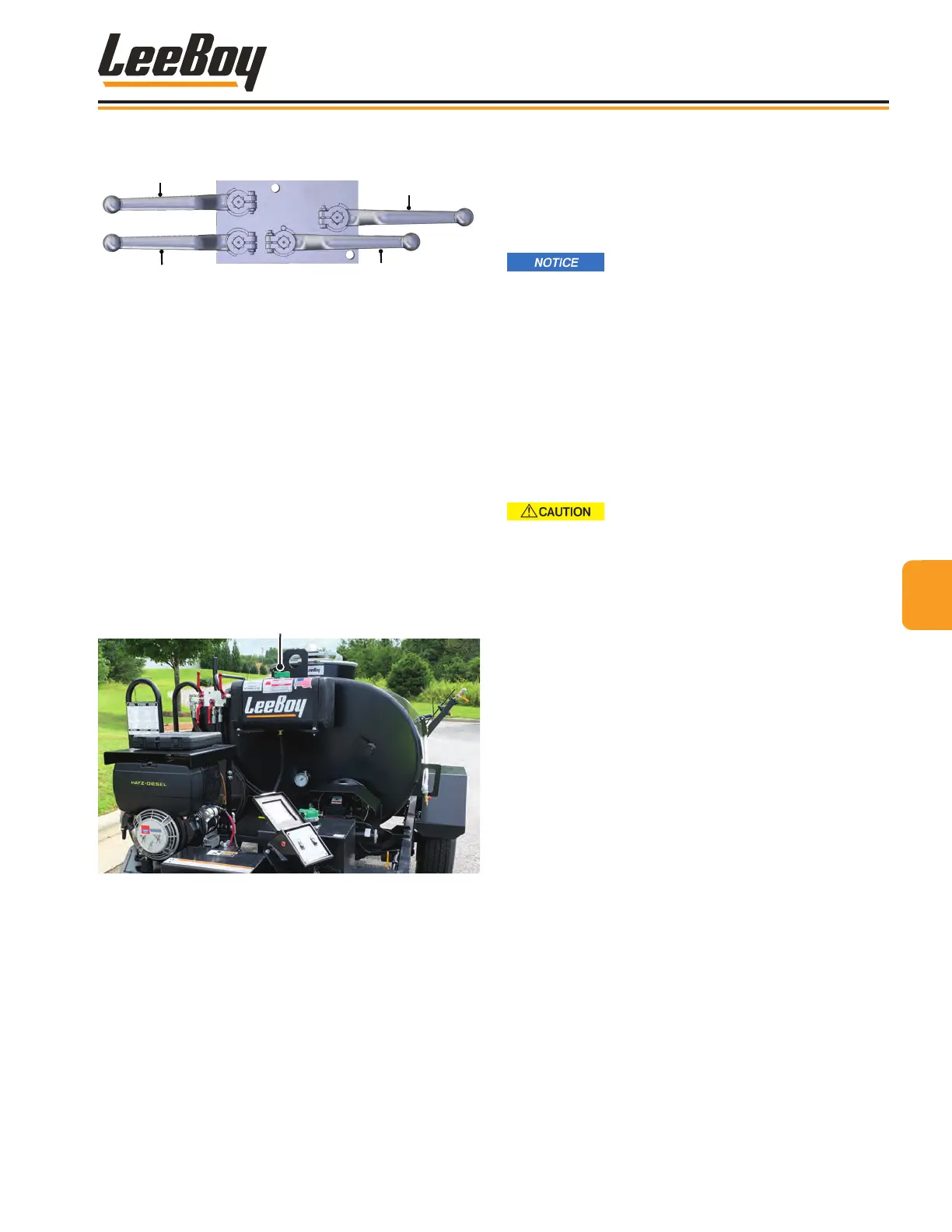

Spray Bar Lever

DOWN

(Toggle)

Circulating Lever

DOWN

Spray Wand Lever

UP

(Toggle)

Selector Lever

UP

Figure 4-20. Upper Valve Settings

3. Pull the circulating valve DOWN to open. (Figure

4-20)

4. Pull the selector valve UP to select the Reverse

Suction mode to begin the process.

5. Toggle the spray wand valve from Open (UP) to

close (DOWN) in one rapid motion two or three

times, making sure not to pause in the center.

• If equipped, then toggle the spray bar valve from

Open (DOWN) to close (UP) in one rapid motion

two or three times, making sure not to pause in

the center.

6. You are now ready to back ush the system.

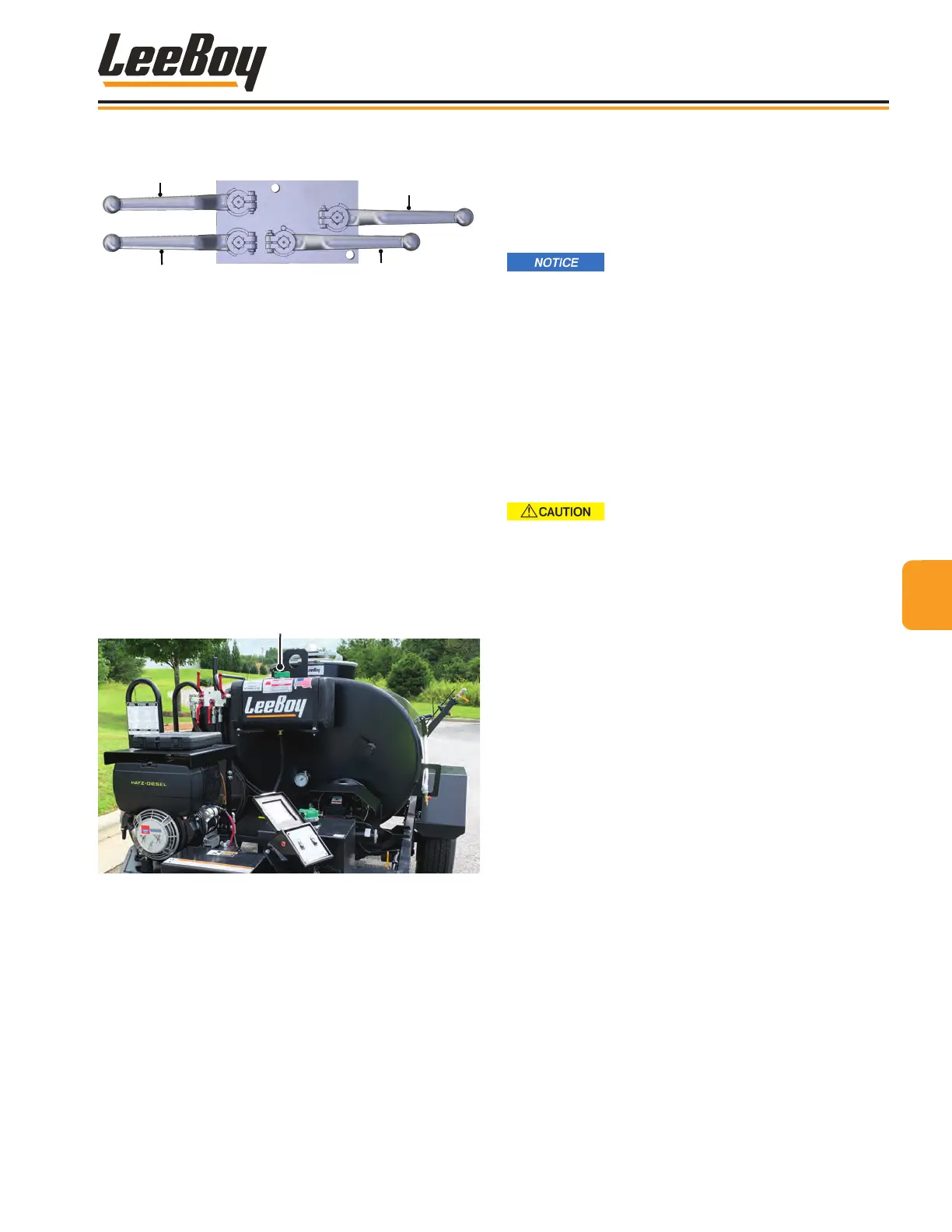

Figure 4-21. Flush Tank

Back FlushBack Flush

DO NOT perform the Back Flush procedure until

you have properly completed the Reverse Suction

procedure to remove excess asphalt material from

the system back into the asphalt tank.

Follow government guidelines for

properly disposing of hazardous materials such

solvents. Consult local authorities or reclamation

facilities for more information. Never dumping these

chemicals onto the ground or into waterways.

Use the following procedure to back ush the system:

1. Park the distributor on level ground.

2. Ensure the ush tank is 90 percent full of solvent (to

allow room for expansion in the tank).

• Solvent can be reused, but replace it with fresh

solvent when it becomes too dirty to use.

ALWAYS loosen the ush tank ller

cap slightly to vent the tank. Tank pressure can build

up during the Back Flush cycle.

3. Ensure the liquid asphalt valve is in the OFF position,

and the following valves are in the CLOSED position

before proceeding. (Refer to Page 3-6 and 3-7,

Valve Controls.)

• Propane tank valve.

• Fuel valve (diesel burner only).

• Sampling valve.

• Circulating valve.

• Spray wand valve.

• Spray bar valve (if equipped).

4. Pull the selector valve DOWN to select other

operational modes. (Figure 4-20)

5. Open the ush valve by pulling the lever UP. (Figure

4-22 on the following page.)

44

Operation

L300 and L600 Tack Distributors 4-21

Loading...

Loading...