Lubricate Wheel HubLubricate Wheel Hub

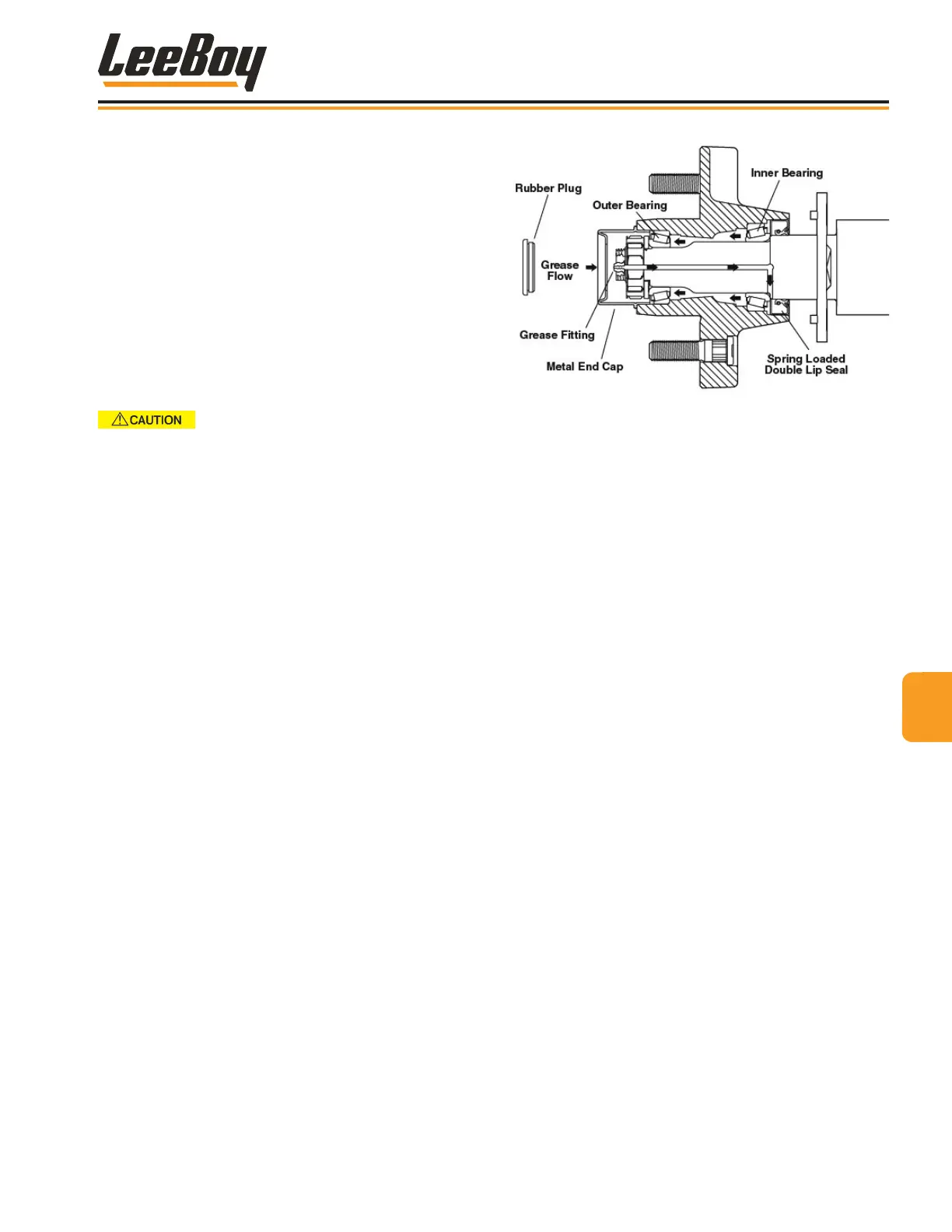

The axle is equipped with the E-Z Lube® system,

which makes lubrication easy without the need for

removing the hubs from the axle. The grease ttings

are conveniently located on the outside of the axle.

Grease is pumped into the tting where it is channeled

to the inner and outer bearings. (Figure 5-12) The

suspension system should be lubricated every 12

months (or more if used in severe conditions).

NOTE: Only use lithium complex NLGI No. 2 grease

with EP, corrosion and oxidation inhibitors,

a viscosity of 80 minimum, and a dropping

point minimum of 419° (215° C).

DO NOT use a pneumatic-powered

grease gun as those inject grease too fast, which can

force grease past the seal or even dislodge the seal.

Figure 5-12. E-Z Lube® System

To lubricate the suspension system:

1. Remove rubber plug. (Figure 5-12)

2. Place a standard manual grease gun onto the tting,

ensuring the gun nozzle is fully engaged to the

tting.

3. While rotating the hub, pump grease slowly into the

tting. (The old grease will ow back out of the cap

around the grease gun nozzle.)

4. When you see clean grease owing back out,

remove the grease gun, wipe off any excess grease,

and replace rubber plug.

55

Maintenance

L300 and L600 Tack Distributors 5-15

Loading...

Loading...