Dirty or loose battery connections can

create high electrical resistance and permit arcing.

To clean the battery:

• Remove any corrosion around terminal connections

and clean with ammonia or a solution of 1/4 lb. (.11 kg)

baking soda in one quart of warm water.

• Ensure vent caps are tight to prevent solution from

entering the cells.

• Ensure the battery terminals and posts are clean and

the battery cable terminals are tight.

If charging the battery:

When connecting a booster battery, connect one end

of the rst jumper cable to the positive (+) terminal of

the dead battery, and the other end to the positive (+)

terminal of the booster battery. Connect one end of the

second jumper cable to the negative (-) terminal of the

booster battery and the other end to the frame of the

distributor with the dead battery.

Fire and Explosion Hazard! Be sure

the battery charger is in the OFF position before

connecting it to the battery.

NOTE: Reversed polarity can damage the electrical

system. It is advisable to disconnect the

negative (-) cable rst and connect it last.

NOTE: When replacing the battery, discard the old

battery properly.

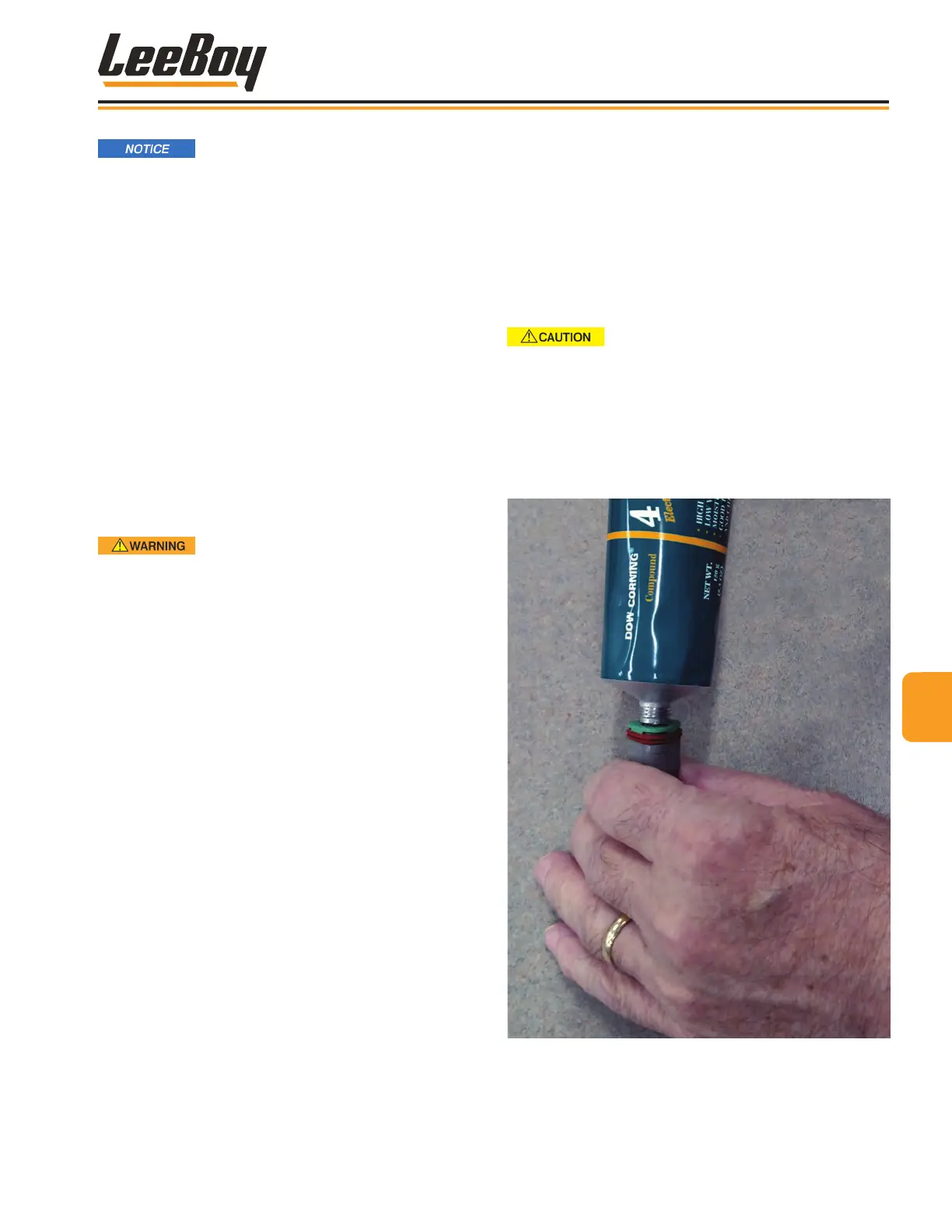

Dielectric GreaseDielectric Grease

Dielectric grease is a nonconductive, insulating

compound applied to electrical connectors. When

applied correctly, a high-quality dielectric grease

displaces debris and moisture in the connector. The

proper application of dielectric grease lls any gaps

between pins or in the connector which prevents debris

and moisture from creating corrosion of the electrical

components.

Equipment damage can occur if using

low-quality, incompatible dielectric grease.

If not applied or incorrectly applied, corrosion can result

that causes rapid increase in resistance, intermittent

connections, overheating, and a variety of electrical

problems. Numerous electrical issues throughout the

machine can be avoided by the proper application and

use of dielectric grease.

Figure 5-10. Correct Application of Dielectric

Grease

55

Maintenance

L300 and L600 Tack Distributors 5-11

Loading...

Loading...