CIRCULATING THE MATERIAL

It is important to mix and distribute the material in the

asphalt tank before spraying the material. Once the

material is properly heated, circulating the hot asphalt at

least ve minutes is a critical rst step for maintaining the

material at a constant temperature and consistency for

uniform spraying. ALWAYS circulate the heated asphalt

material before spraying.

The circulating system has an engine-driven pump to

circulate material through the spray wand (and spray

bar if equipped). The tack distributor delivers a volume

of asphalt that is regulated by variables, including the

temperature of the asphalt material, nozzle size and PSI

setting at the relief valve.

The tack distributor is equipped with 1/4-inch nozzles

(wand and spray bar) that deliver a 95-degree angle of

spray. It is important that the operator applies constant

and uniform pressure for uniform output.

NOTE: If equipped with the optional spray bar, the

material will also circulate through the spray

bar system.

If unable to circulate the tank after

heating the material for 15 minutes, turn off the

burners, but leave the blower running for one (1)

minute. DO NOT ATTEMPT TO REHEAT the material

for at least 30 minutes.

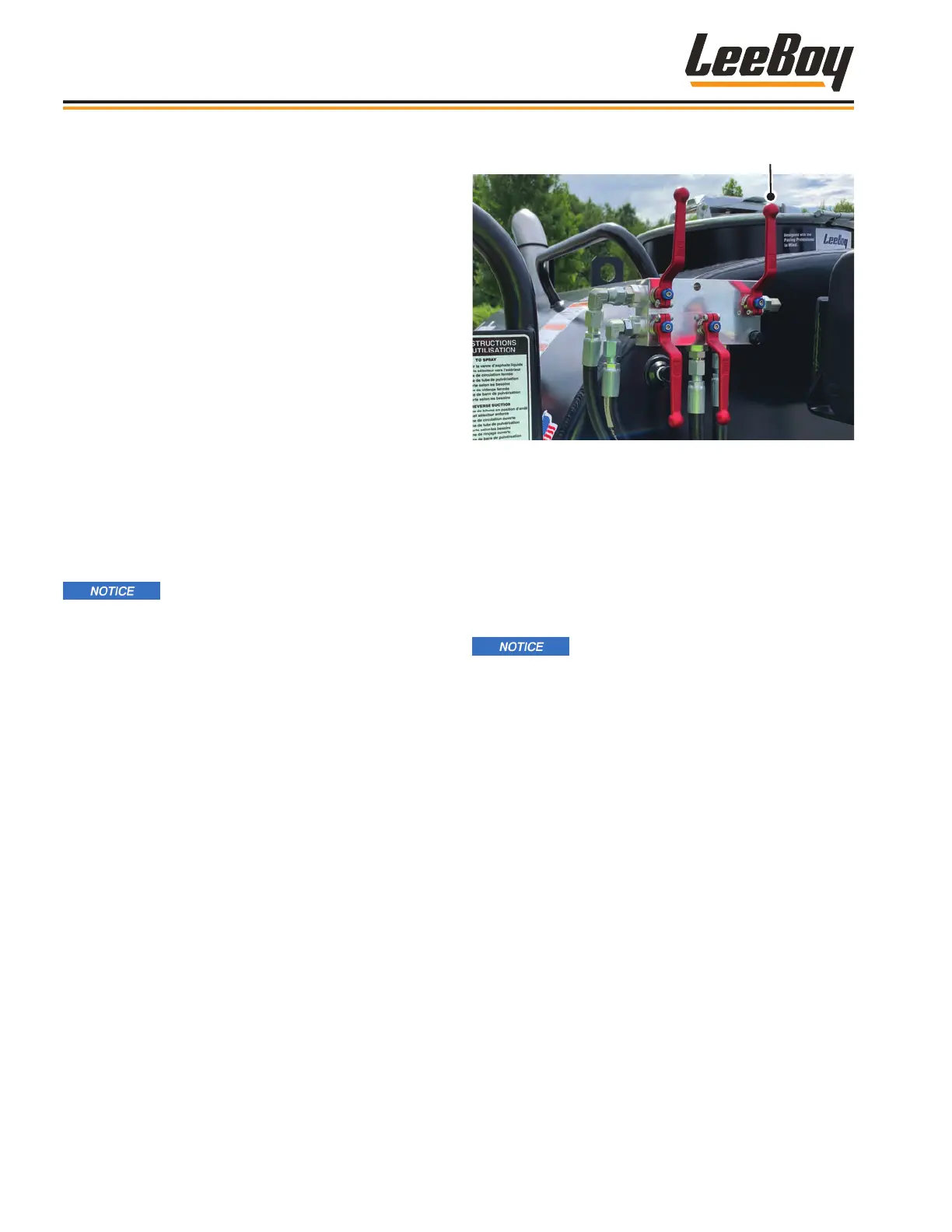

Circulating Valve

Figure 4-13. Circulating Valve (Open Position)

To circulate the asphalt material:

1. Park the distributor on level ground.

2. Using a ashlight, check inside the tank to be sure

the burner ue tubes in the bottom of the tank are

covered by at least one (1) inch (2.5 cm) of material

before lighting burner.

It cannot be emphasized enough that

the burner ue must be covered with at least one (1)

inch (2.5 cm) of material.

3. Ensure ALL valves on the unit are in the CLOSED (or

OFF) position before proceeding. (Refer to Page

3-6 and 3-7, Valve Controls.)

• Propane tank valve.

• Fuel valve (diesel burner only).

• Shut-Off valve.

• Pilot valve.

• Ignitor wand valve.

• Liquid asphalt valves.

• Flush valve.

• Circulating valve.

• Spray wand valves.

• Sampling valve.

• Spray bar valves, if equipped with this option.

Operation

L300 and L600 Tack Distributors4-16

Loading...

Loading...