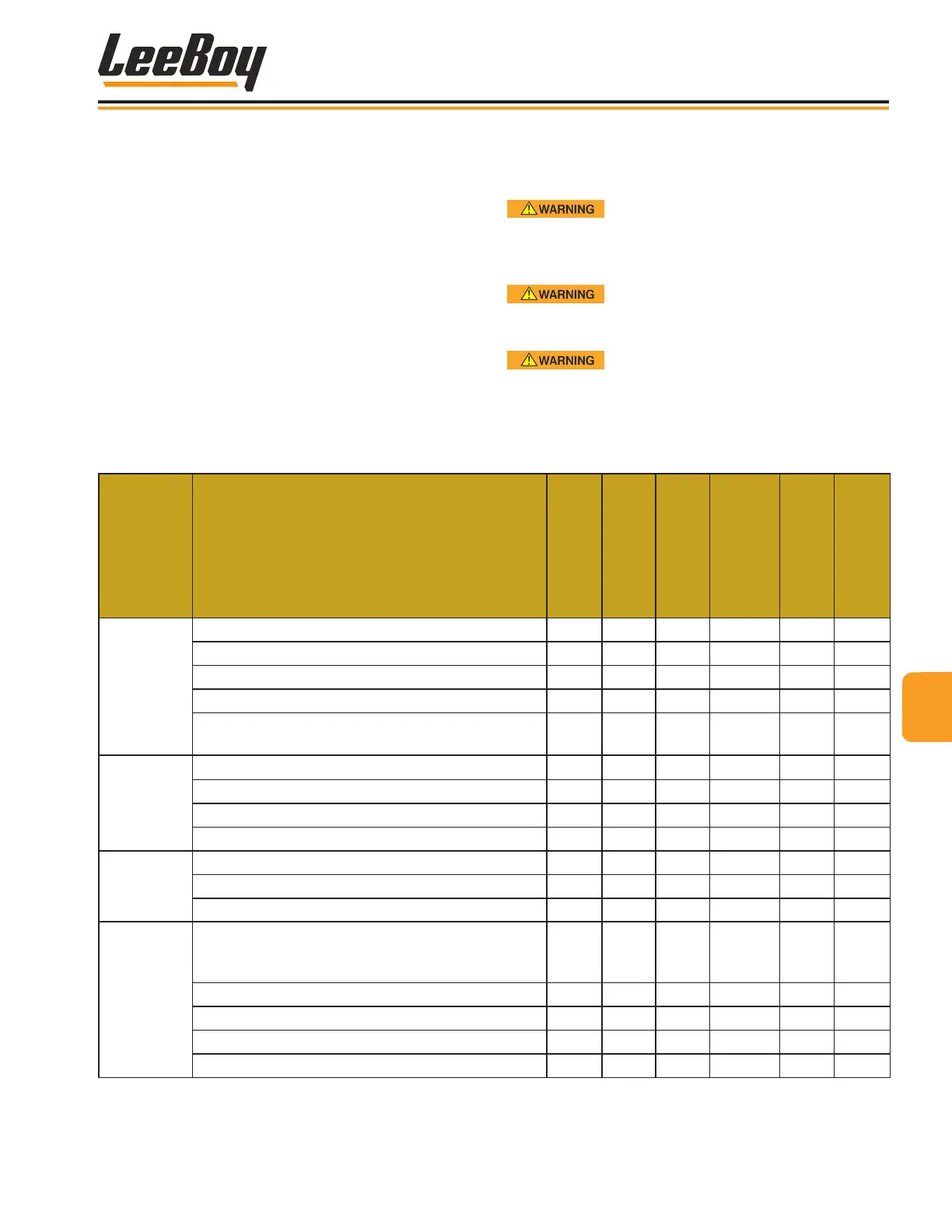

MAINTENANCE SCHEDULE

Follow the procedures in this section for routine

and general maintenance on the LeeBoy L300 and

L600 Tack Distributors to maintain the machine in

top operating condition. One of the most important

requirements for satisfactory tack distributor

performance is a clean machine. Mechanical failures

are often due to equipment that has become so covered

with excess dirt or dried material residue.

Inspect your distributor daily checking for loose bolts,

uid leaks, worn or damaged hoses, and debris or dirt

accumulations. Repair or replace worn or damaged

parts to prevent damage to components. Also perform

any engine preventive maintenance described in your

Engine Operator’s Manual.

Table 5-1. Periodic Maintenance Schedule

SYSTEM ITEM

Every 10 Hours

Daily

Every 50 Hours

Weekly

Every 100 Hours

Monthly

Every 250 Hours

Quarterly

Every 500 Hours

Semi-Annually

Every 1000 Hours

Annually

Gas Engine

(Standard)

Change oil. (Initial 50 Hours)* X

Change air lter element. X

Clean sediment cup. X

Clean combustion chamber. X

Check idle speed and valve clearance. Adjust if

needed.

Diesel

Engine

(OPTION)

Change oil and clean oil lter. (Initial 50 Hours)* X

Check air lter. Replace lter if needed. X

Change air lter element.

Change fuel lter. X

Electrical

Clean spark plug. X

Replace spark plug. X

Service battery (if equipped with this option). X

Trailer-

Mounted

Units

Check brakes for leaks, faulty wires, and damaged

or worn brake lines, seals and wheel bearings.

Repair or replace worn components.

X

Adjust brakes. X

Check tire pressure. Inate or deate if needed. X

Tighten and torque wheel nuts and bolts. X

Lubricate wheel hub. X

* The engine manufacturer recommends an oil change the rst month of operation, then every six months.

Do not neglect ordinary adjustments, lubrication and

periodic maintenance. Repair or replace worn or

damaged parts to prevent damage to components.

DO NOT perform maintenance while

the engine is running. To prevent accidental start-up,

disconnect the spark plug (gas engine) or battery

negative pole (electric start).

DO NOT smoke or work near any

sparks or open ame. Use only a non-ammable

solvent to clean parts.

Always use the appropriate and

correct sized tools for the task at hand to prevent

damage or possible injury.

55

Maintenance

L300 and L600 Tack Distributors 5-3

Loading...

Loading...