Wheels and TiresWheels and Tires

Check tires for excessive wear, correct tire pressure

and any damage regularly.

• Check tires and wheels for cuts, bubbles, damaged

rims or missing wheel bolts or nuts.

• Protect tires from contact with petroleum products

and chemicals.

• Check that lug nuts are tight.

It is extremely important to apply and maintain the

proper torque to prevent loose wheels, broken studs

and possible dangerous separation of wheels from the

axle. Be sure to use only fasteners matched to the cone

angle of your wheel. ALWAYS use a torque wrench.

NOTE: Wheel nuts and bolts should be torqued

before rst road use and after each wheel

removal.

The maximum torque level that can applied to the wheel

studs are shown in the following table:

Table 5-2. Maximum Torque

Stud Size Maximum Torque

1/2” - 20 UNF, Class 2A 120 ft lbs

9/16” - 18 UNF, Class 2A 170 ft lbs

5/8” - 18 UNF, Class 2A 325 ft lbs

If replacing wheels:

• Be sure to match wheel to the axle hub. Numerous

bolt circle dimensions are available.

• Ensure the wheels are strong enough with the correct

pressure rating for the maximum load-carrying

capacity of your unit.

• Match replacement wheel with the same offset wheel

as originally equipped. This is the relationship of

the center line of the tire to the hub face of the axle.

Failure to match offset can results in reducing the

load-carrying capacity of your axle.

Change TireChange Tire

Always check tire ination pressure before operating.

Tire wear should also be checked frequently. (Table

5-3)

To change a tire:

1. Park distributor on a at surface and place a block

or jack stand on each side of the tire not being

replaced.

2. Raise the distributor using a tire jack on the frame

near the tire being changed. DO NOT raise the

frame too high.

3. Loosen and remove lug nuts BY HAND to prevent

cross threading.

4. Carefully remove tire.

5. Install replacement tire.

6. Replace lug nuts, tightening alternately. Torque to

85 ft. lbs. (115 Nm).

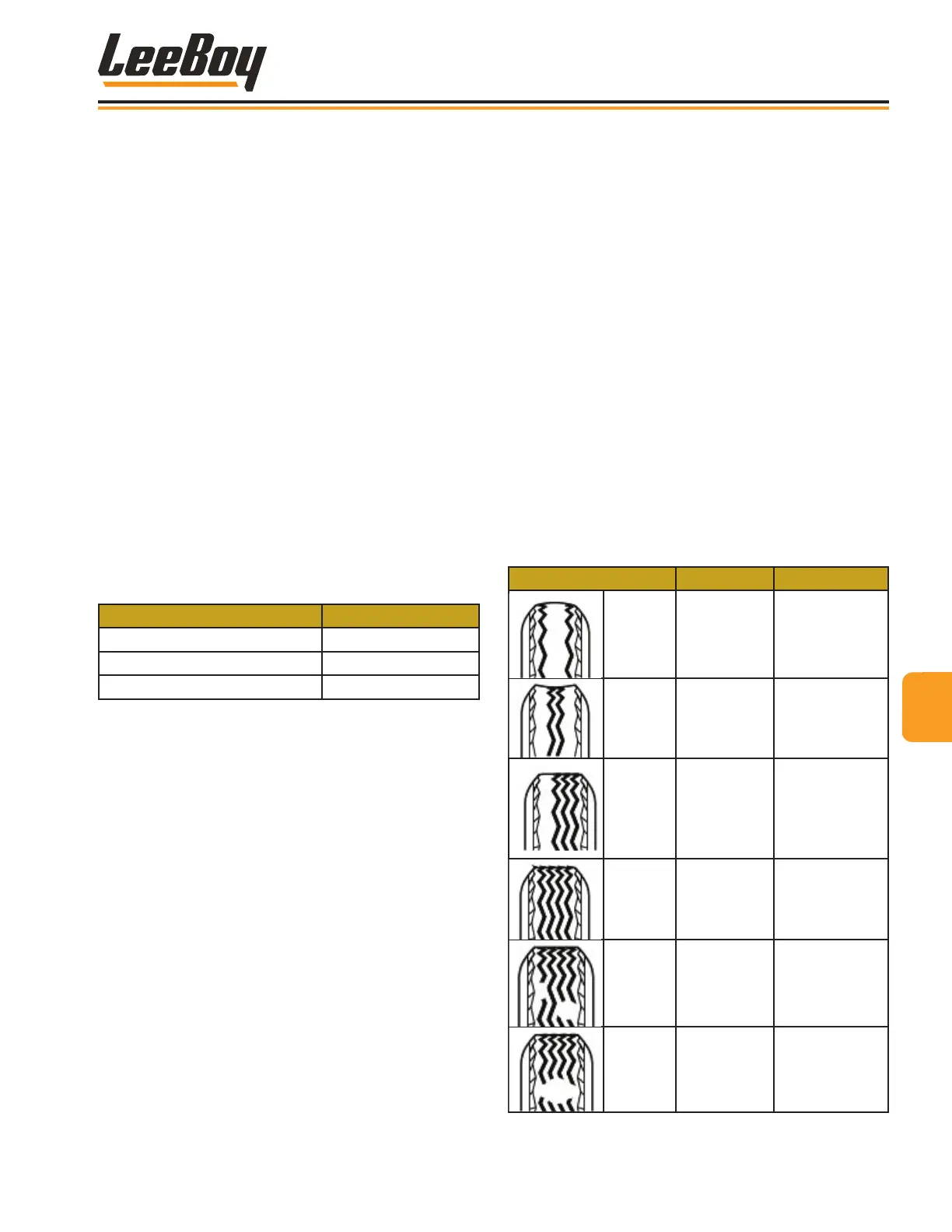

Table 5-3. Tire Wear Chart

WEAR PATTERN CAUSE ACTION

Center

Wear

Over

Ination

Deate tire to

correct load

level.

Edge

Wear

Under

Ination

Inate tire to

correct load

level.

Side

Wear

Loss of

camber or

overloading.

Get alignment.

Ensure load

doesn’t

exceed axle

rating.

Toe

Wear

Incorrect

toe-in.

Get alignment

service.

Cupping

Wheels out

of balance.

Check balance

and bearing

adjustment.

Flat

Spots

Wheels

locked and

tire skidding.

Adjust brakes.

55

Maintenance

L300 and L600 Tack Distributors 5-13

Loading...

Loading...