NOTE: The least amount of pressure on relief, the

longer the life of the pump.

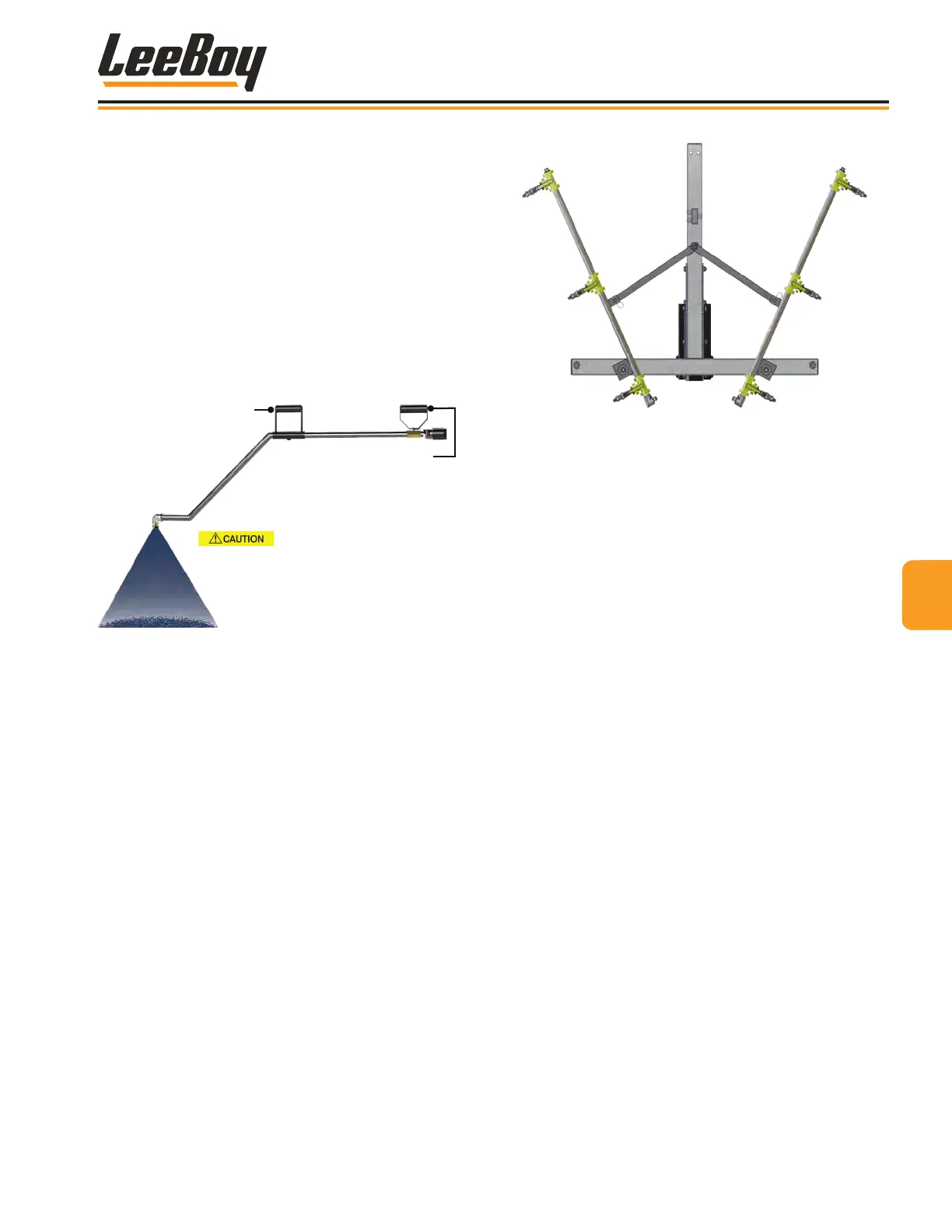

8. Hold the spray wand rmly by both hand grips, with

the spray end away from your body, then open the

grip valve by turning it counterclockwise as shown in

Figure 4-17 to begin spraying.

• You can close the hand spray valve by turning

the handle clockwise to its original position as

needed.

NOTE: The grips will remain cool as the hot asphalt

ows through the wand, however, DO NOT

spray without wearing protective gloves.

Grip

Grip and

Spray Valve

Keep bystanders at a safe distance

to prevent injury from hot asphalt spray.

Figure 4-17. Hand Spray Wand with Grip Valve in the

OPEN (ON) Position

9. Direct the wand using long, sweeping arcs while

spraying to evenly distribute the material.

NOTE: Hold the spray nozzle end nearer to the

ground if weather conditions are windy.

10. When nished spraying, turn the liquid asphalt valve

OFF by turning it LEFT.

11. Alternate opening and closing the spray wand grip

valve a few times to draw excess asphalt from the

spray wand and hose until any material ow has

ceased, then close valve by turning it clockwise.

Reel in hose and return spray wand to its mount.

12. Pull the spray wand valve lever UP.

13. Perform the Reverse Suction and Back Flush

procedures described on Pages 4-20 to 4-21.

NOTE: When allowing machine to run for short

periods of time without spraying, open and

close the circulating valve a few times to

relieve excessive pump pressure.

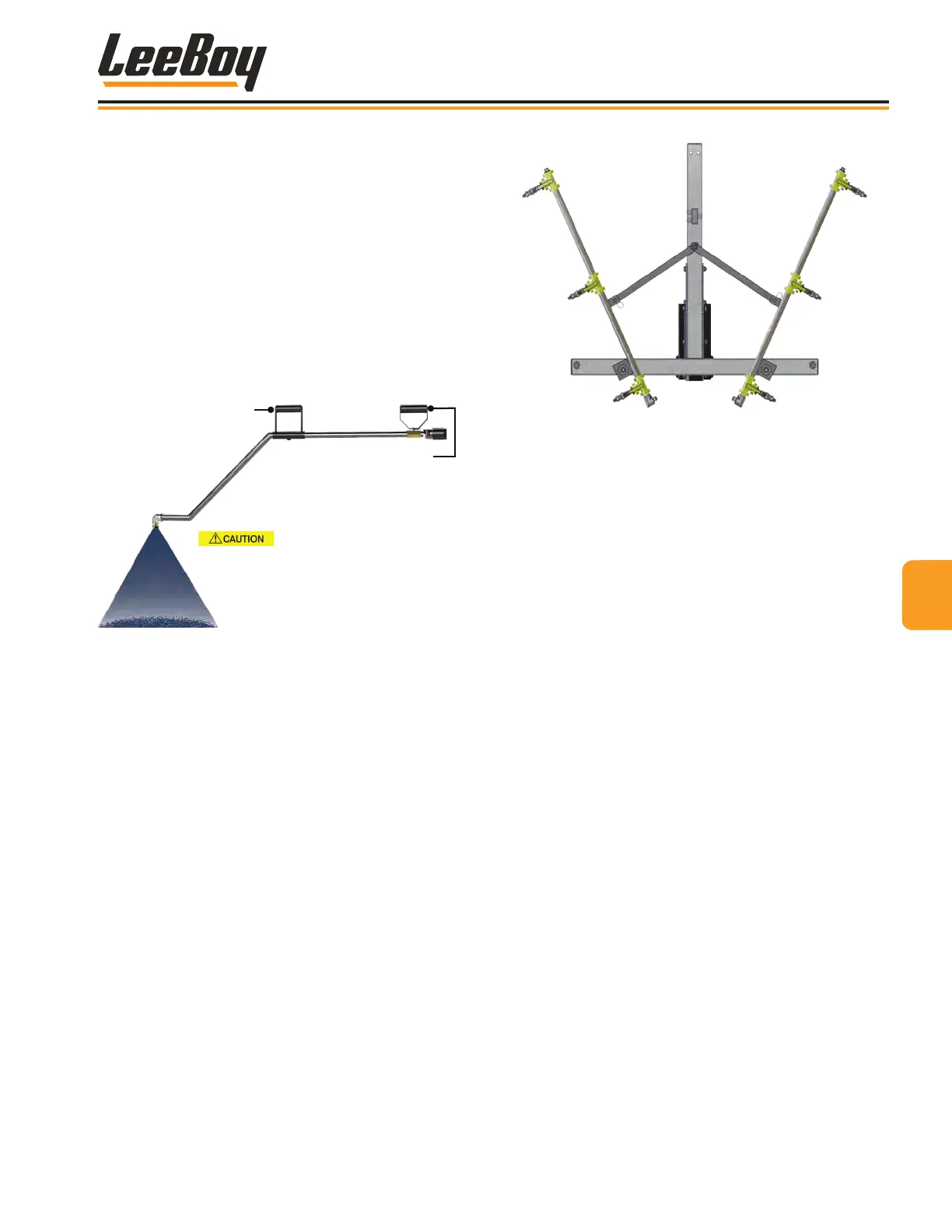

Figure 4-18. Optional Spray Bar

Spray Bar (Option)Spray Bar (Option)

The optional spray bar provides the ability to distribute

tack material over a larger area, i.e., a road or driveway

surface. Mounted on the rear of the unit, the spray

bars, one on each side, are equipped with individual

spray nozzle valves (three on each spray bar) evenly

spaced across. The two spray bars fold down to extend

the spraying width as needed for a coverage width up

to eight (8) feet (2.4 meters). The spray nozzles and

constant pressure along the length of the spray bars

work together to produce a triple-overlap, fan spray

pattern for uniform application. (Figure 4-18)

Proper surface coverage and spray pattern depends

upon the condition of the spray nozzles. The corrosion-

resistant nozzles are designed for long-lasting, trouble-

free performance. Factors that can increase nozzle

wear and negatively impact performance are plugging,

build-up or caking inside the nozzle.

• Inspect the spray nozzles daily to ensure they are free

from clogs and operating properly.

• Treat nozzles with care. The nozzle orice is very

precise, so be careful to avoid damage.

• Examine spray pattern and ow rate. A clogged

nozzle is very easy to notice.

• If a nozzle becomes clogged, clean or replace it

immediately. Clean the nozzle slots, being careful not

to damage the nozzle opening as the spray pattern will

be adversely affected. Cleaning tool should be softer

than construction material. NEVER clean the orice

with metal objects.

• To replace a spray nozzle, simply unscrew nozzle

from its mount and remove, insert new nozzle and

screw back into place securely.

44

Operation

L300 and L600 Tack Distributors 4-19

Loading...

Loading...