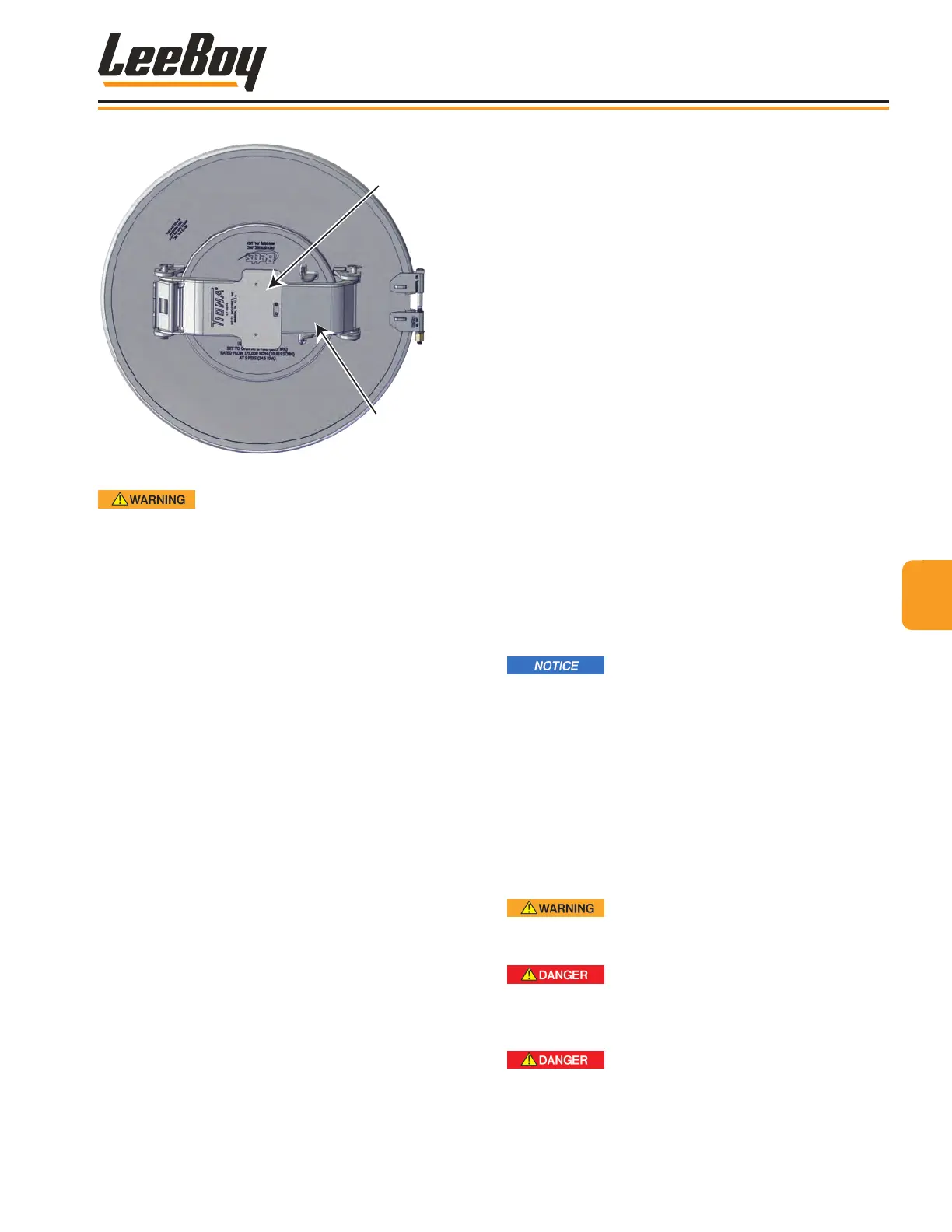

Top Latch

Bottom Latch

Figure 4-8. Manhole Hatch

Fumes from asphalt materials are

poisonous and should not be inhaled. DO NOT lean

over the tank manhole cover when lling to avoid

hot gases, fumes or the possibility of hot asphalt

contact.

To load material:

1. Park the unit (or vehicle if skid-mounted) on a level

surface.

2. Ensure ALL valves on the unit are in the CLOSED

position (Refer to Page 3-6 and 3-7, Valve

Controls):

• Propane tank valve.

• Fuel valve (diesel burner only).

• Pilot valve.

• Shut-Off valve.

• Ignitor wand valve.

• Liquid asphalt valve.

• Flush valve.

• Circulating valve.

• Spray wand valves.

• Sampling valve.

• Spray bar valves, if equipped with this option.

3. Pull up the top latch and then the bottom latch to

open the manhole hatch. (Figure 4-8)

4. Insert material hose into the tank and ll 90 percent

full. DO NOT OVERFILL.

5. Close bottom latch, then top latch securely.

HEATING THE MATERIAL

The burner system produces heat that is dissipated

through the asphalt. Because asphalt resists heat

conduction, the amount of time necessary to heat the

asphalt to a sufcient temperature for spraying will vary

depending upon the type of material, tank size, amount

of material in the tank and the weather temperature.

(See Table 4-2, Asphalt Temperature Guide on the

following page.) Be sure to contact your asphalt

supplier for more information about their asphalt

product.

NOTE: Only operate the burner for a short time

(no more than 15 minutes) to allow heat to

dissipate throughout the material.

NOTE: The asphalt temperature must reach the

manufacturer’s recommended temperature

before starting the engine. Trying to spray

asphalt before it is warm enough will

damage the pump. (See Table 4-2, Asphalt

Temperature Guide, on the following page.)

The tack distributor is equipped with an LPG propane

burner system (or optional diesel burner system

described on Page 4-15). Flame ignites the burner that

is then directed through ue tubes in the bottom of the

asphalt tank to heat the asphalt material. (Figure 4-9)

It cannot be emphasized enough that

the burner ue must be covered with at least one (1)

inch (2.5 cm) of material.

NOTE: If it is necessary to heat asphalt that has

cooled more than 20° - 30° F (-6.6° to -1.1°

C) below the manufacturer’s recommended

spraying temperature, use extreme care

when reheating the material. If the asphalt

is heated too quickly or gets too hot, spots

will be created near the ue tubes that could

damage them or cause the asphalt material

to break down.

ALWAYS keep a fully-charged, dry

chemical re extinguisher within easy reach when

operating the burners.

DO NOT operate the burner system if

the tank is leaking or fuel spills have occurred. Fire

or an explosion can occur and result in serious

injury.

NEVER operate the burners or the

tack distributor in a conned area. Vapor build-up

can ignite.

44

Operation

L300 and L600 Tack Distributors 4-11

Loading...

Loading...