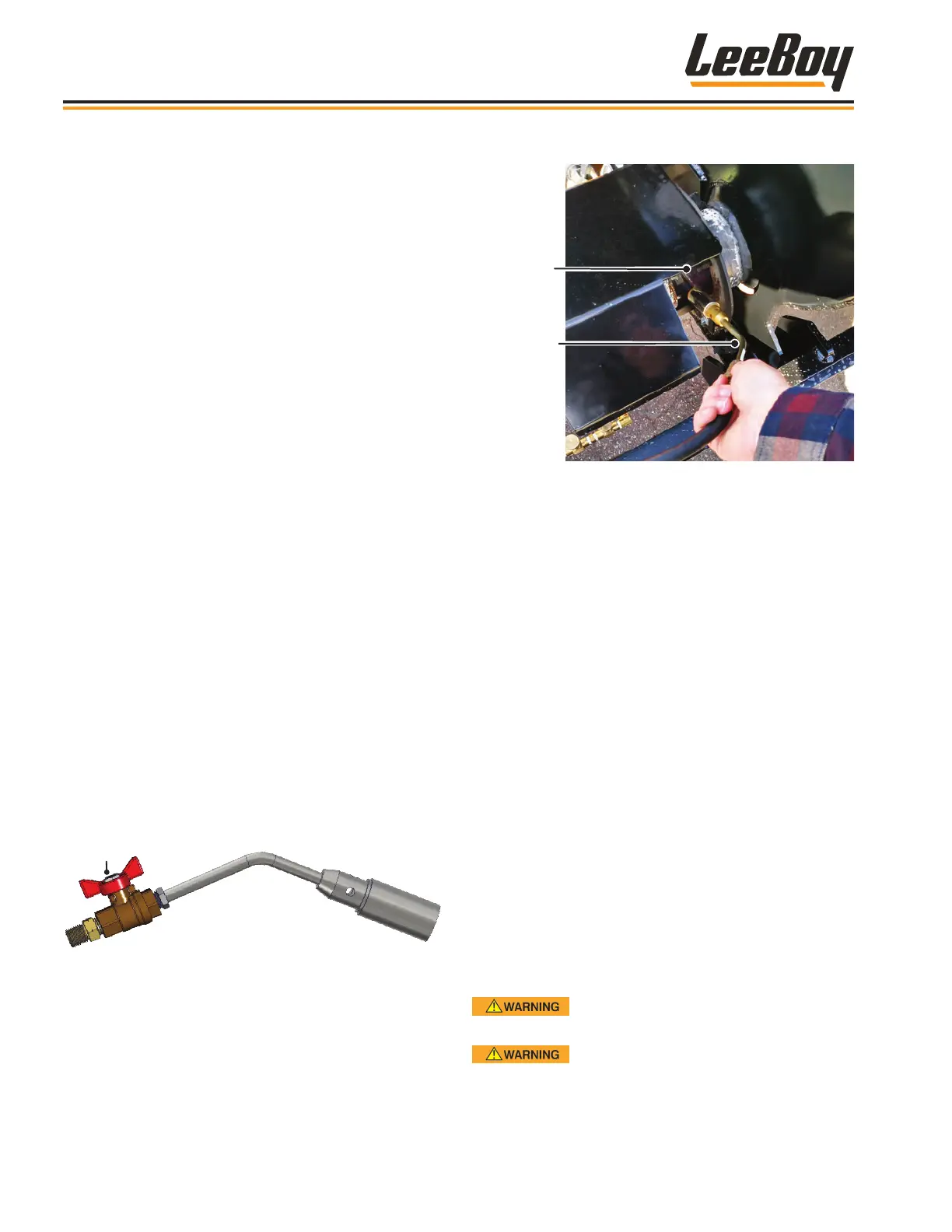

8. Light ignitor using a torch striker. (Figure 4-11)

Ignitor

Wand

Burner

Ignition Tube

Figure 4-11. LPG Burner Ignitor

9. Hold the lit ignitor wand at the burner ignition tube at

the burner as shown in Figure 4-11.

10. If it doesn’t light immediately:

• Shut off the gas ow by turning the shut-off valve

clockwise. (Figure 4-9 on Page 4-13)

• Wait 30 seconds to allow pockets of trapped gas

to purge.

• Repeat this p

1

rocedure until burner is lit.

11. After the burner is lit, close the wand ignitor valve by

turning it clockwise. (Figure 4-10)

12. Fully open the shut-off and pilot valves by turning

them clockwise. (Figure 4-9)

13. Return ignitor wand to its storage bracket.

14. Monitor the asphalt temperature gauge to

ensure the liquid asphalt is heated to the desired

temperature according to material specications .

This should NEVER exceed 180° F (82° C). (Figure

4-9)

NOTE: Monitor the temperature several times while

working.

15. After asphalt has reached the appropriate

temperature, start the engine. (Page 4-4)

Never start the engine unless there is

enough tack material circulating in the system.

DO NOT heat emulsied asphalt

more than 185° F (29.9° C). Elevated temperatures

evaporate the water and will produce an asphalt

layer inside the tank that will be difcult to remove.

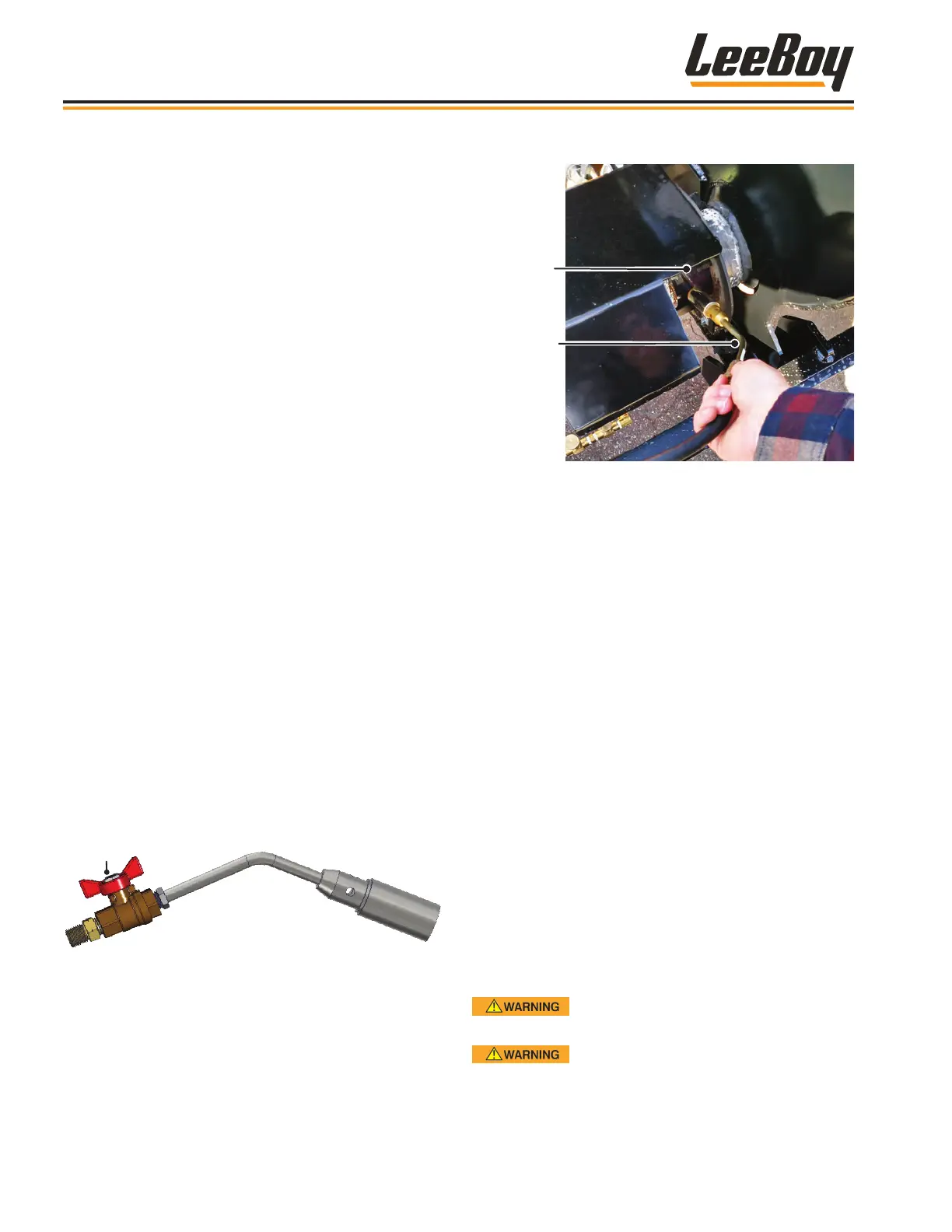

3. Ensure ALL valves on the unit are in the OFF

position. (Refer to Page 3-6 and 3-7, Valve

Controls.)

• Propane tank valve.

• Fuel valve (diesel burner only).

• Pilot valve.

• Shut-Off valve.

• Ignitor wand valve.

• Liquid asphalt valves.

• Flush valve.

• Circulating valve.

• Spray wand valves.

• Sampling valve.

• Spray bar valves, if equipped with this option.

4. Open the propane tank valve to start the propane

gas ow by turning valve counterclockwise. (Figure

4-9)

5. Regulate the propane pressure to 15 - 17 PSI

(maximum) by adjusting knob on the regulator.

(Figure 4-9)

• Turn regulator knob clockwise to increase

pressure.

• Turn regulator knob counterclockwise to

decrease pressure.

6. Turn the shut-off valve counterclockwise to allow

gas ow to the burner. (Figure 4-9)

7. Remove the ignitor wand from its stowed position

and open its valve by turning counterclockwise.

(Figure 4-10)

Figure 4-10. Ignitor Wand Valve

Operation

L300 and L600 Tack Distributors4-14

Loading...

Loading...