Wiring of digital frequency input / digital frequency output5.9

5.9−2

EDSVF9383V EN 7.1−04/2012

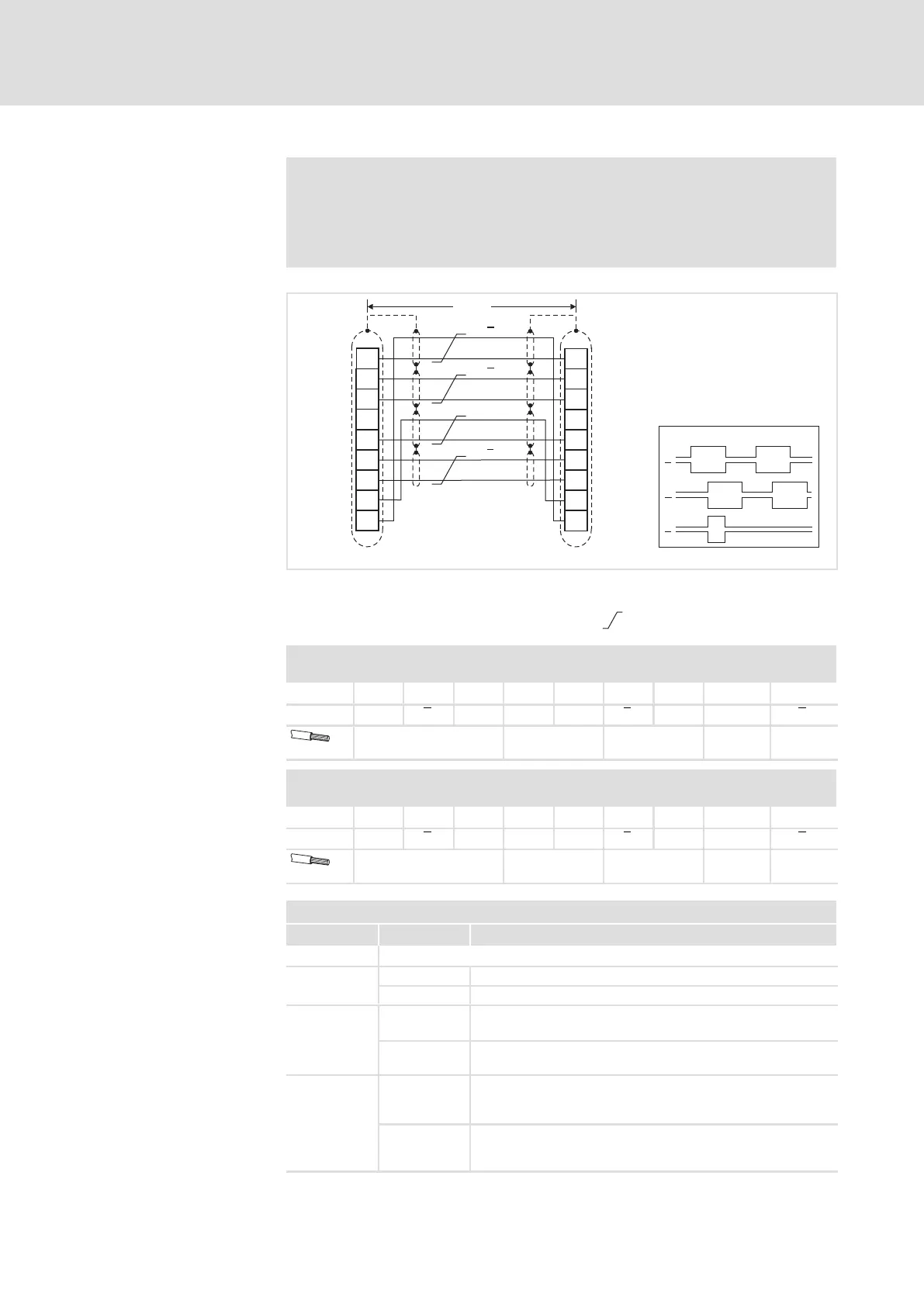

Note!

ƒ We recommend to use Lenze system cables for wiring.

ƒ For self−made cables only use cables with shielded cores

twisted in pairs.

B

Enable (EN)

Lamp

control (LC)

GND

Z

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

A

X9X10

<50m

A

B

Z

A

A

B

Z

B

Z

9300VEC019

Fig. 5.9−1 Connection of digital frequency input (X9) / digital frequency output (X10)

X9 Slave drive Signals for CW rotation

X10 Master drive

Cores twisted in pairs

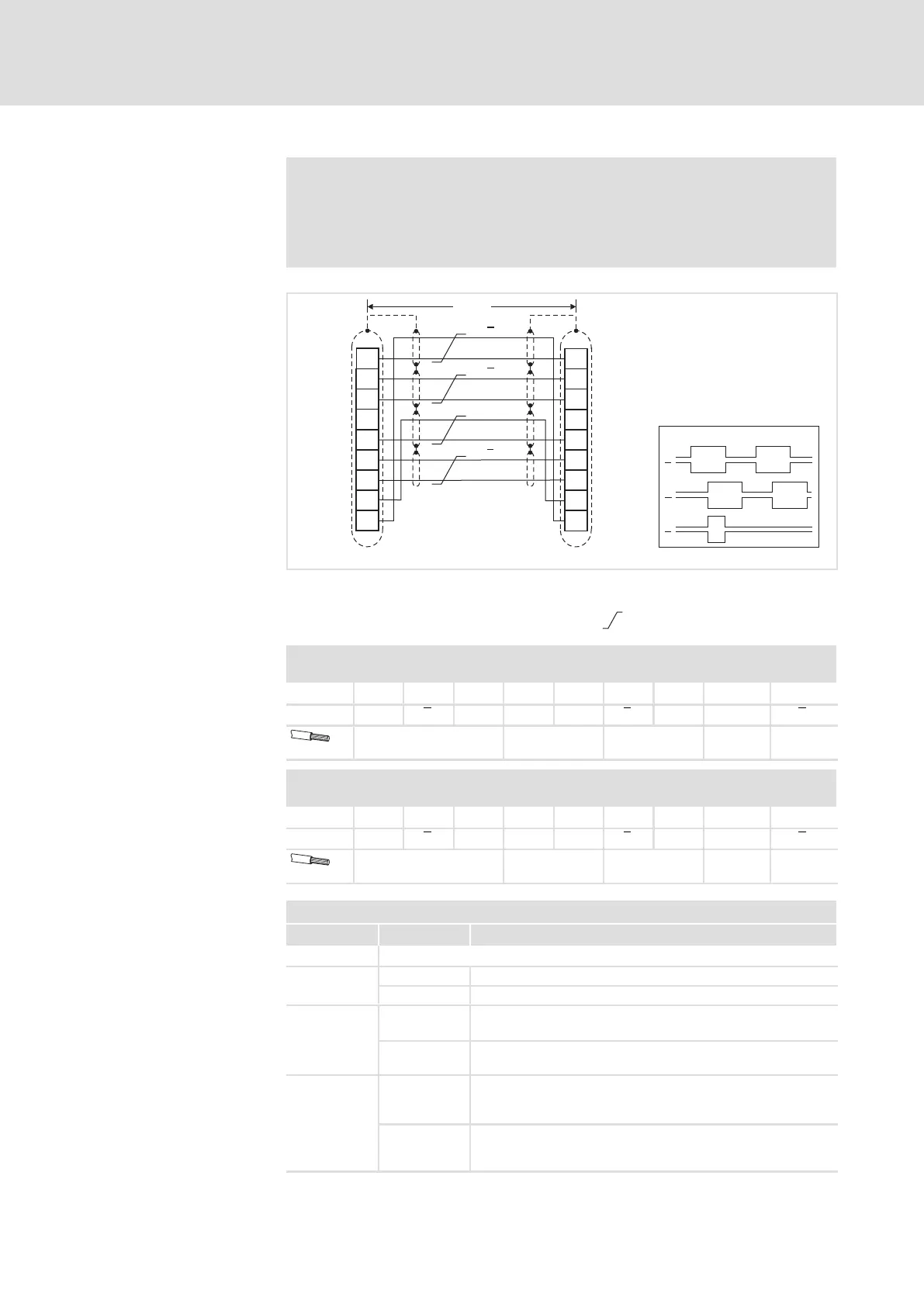

X9 − Digital frequency input

Connector: Pin, 9−pole, Sub−D

Pin 1

2 3 4 5 6 7 8 9

Signal B A A +5 V GND Z Z LC B

0.14 mm

2

(AWG 26)

0.5 mm

2

(AWG 20)

0.14 mm

2

(AWG 26)

0.5 mm

2

(AWG 20)

0.14 mm

2

(AWG 26)

X10 − Digital frequency output

Connector: Socket, 9−pole, Sub−D

Pin 1

2 3 4 5 6 7 8 9

Signal B A A +5 V GND Z Z EN B

0.14 mm

2

(AWG 26)

0.5 mm

2

(AWG 20)

0.14 mm

2

(AWG 26)

0.5 mm

2

(AWG 20)

0.14 mm

2

(AWG 26)

Evaluation of the input signals at X9

Code Function

C0427 = 0

CW rotation Track A leads track B by 90 ° (positive value at DFIN−OUT)

CCW rotation Track A lags track B by 90 ° (negative value at DFIN−OUT)

C0427 = 1

CW rotation Track A transmits the speed

Track B = LOW (positive value at DFIN−OUT)

CCW rotation Track A transmits the speed

Track B = HIGH (negative value at DFIN−OUT)

C0427 = 2

CW rotation Track A transmits the speed and direction of rotation (positive

value at DFIN−OUT)

Track B = LOW

CCW rotation Track B transmits the speed and direction of rotation (negative

value at DFIN−OUT)

Track A = LOW

Wiring

Adjustment

Loading...

Loading...