LogTag TRIX-8/TRIX-16 Work Instruction Manual Revision 9.20 Page 36/53

Procedure:

1. Store units to be testing in rack arrangement in same area as testing interfaces.

Each unit to be tested is required to be held in the area with the testing interface for a period of at least

10minutes before being tested to ensure it is at similar temperature to the interface.

Arrange unit stacking on production line area to allow for this.

2. Insert LogTag to be tested into an interface and observe that tests run without error.

NOTES:

1. During this test, the temperature sensor reading is checked and is compared to the temperature sensor

installed in the interface. If the unit or the interface has been over-handled or the temperatures have not

been allows to stabilise then the Verify temperature sensor reading part of the test will fail.

2 Recorded readings are saved in the ‘Check-Final’ directory

(C:\Program Files\LogTag Recorders\LogTag Station\Check-Final’) under a directory coded with the year

and week of year. Data is stored in format that can be read using LogTag Analyser.

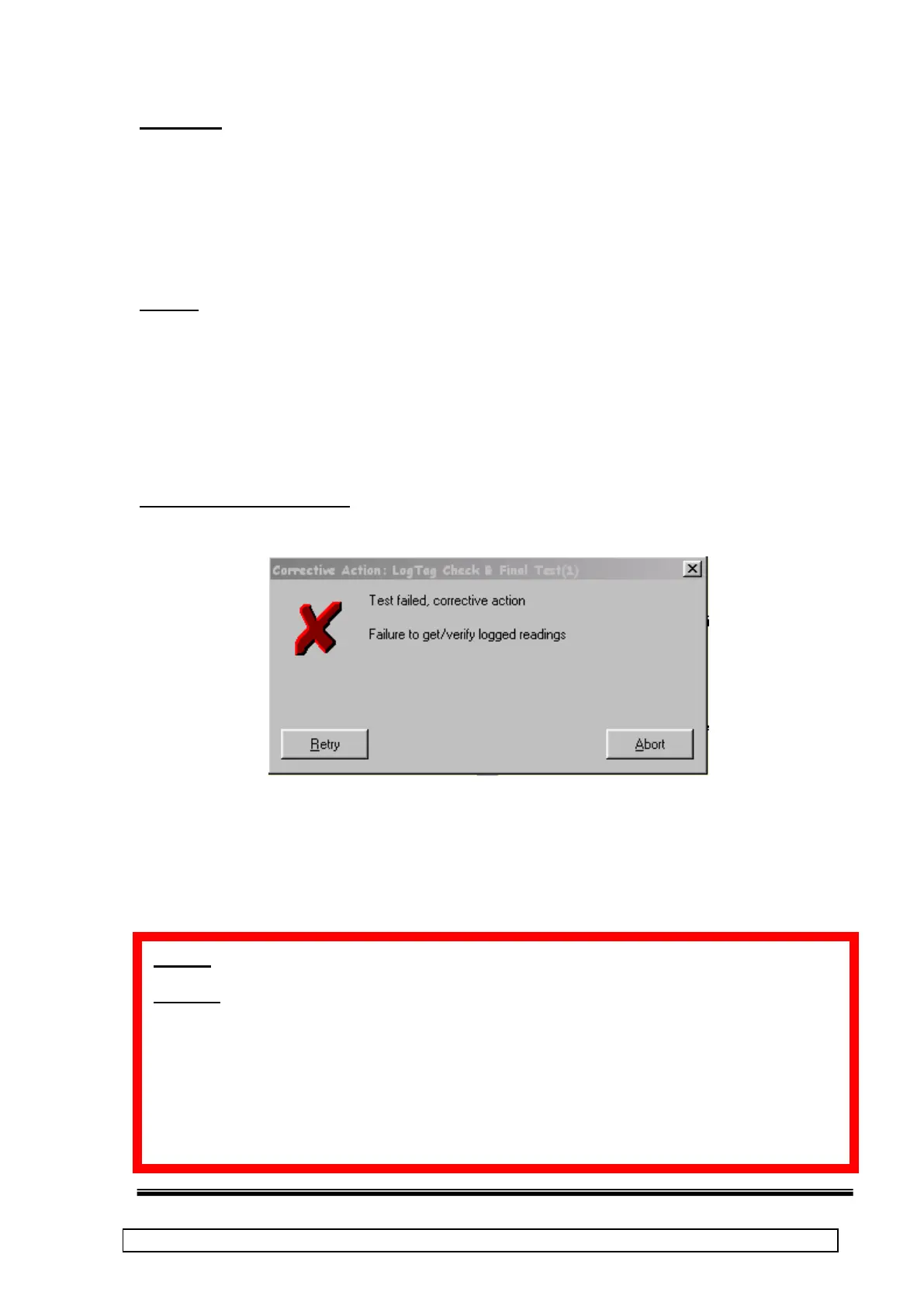

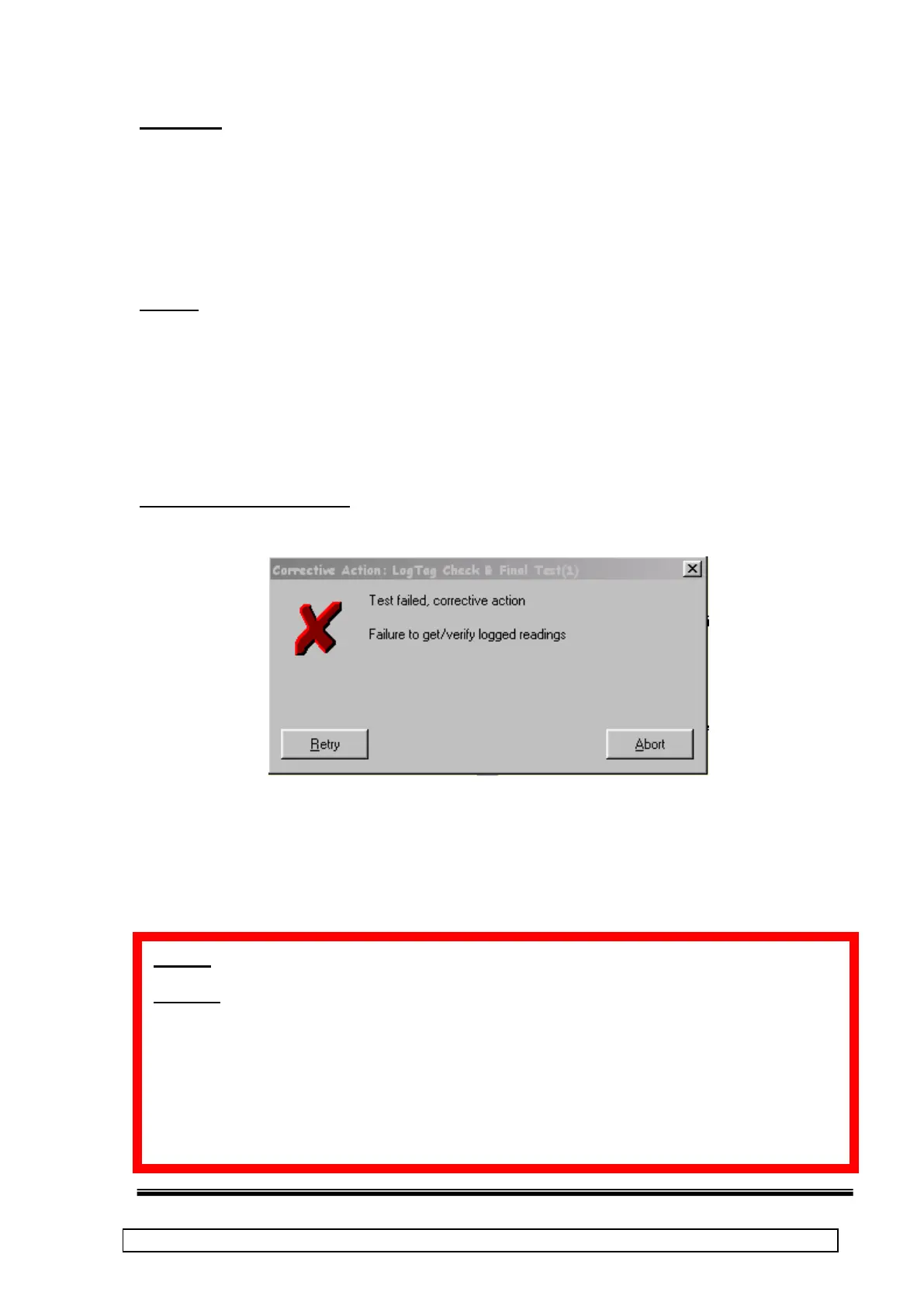

Failures & Corrective action.

If a test fails then a display similar to below will open describing failure.

Options are to Retry or Abort the test.

If the product will not pass the test – remove it from the interface and click ABORT.

Place in separate marked container for service check. Rejected products must be clearly identified and

kept apart from accepted products

ALWAYS use the Close button to exit program

DO NOT reset or switch off computer while it is running any test otherwise production log files may

become corrupted !!

Product that has passed Check Final is not in a correct state for shipping – all product must pass

through the customisation phase before shipping. Product direct shipped from Check-Final without

customisation will not be able to be used by end users.

Loading...

Loading...