ENGINE AND ENGINE SYSTEMS CD3340B/YB4411

6-12

Published 04/07/2015 Control # 569-00

11. Insert the installation shim (Figure 6-3) behind coupling

sleeve (4, Figure 6-4) as shown in Figure 6-14.

12. Install pump (1, Figure 6-4) as shown. Apply Loctite®

243 to the threads of capscrews (21, Figure 6-4). Attach

the pump with capscrews (21), lockwashers (22), and

flat washers (23). Tighten the capscrews to a torque of

87 Nm (64 lb-ft).

13. Push pump coupling hub (5, Figure 6-4) towards the

engine with socket head capscrews (13) against

coupling sleeve (4), the sleeve against the shim, and the

shim against drive coupling (2). Tighten clamping bolt

(16, Figure 6-4). Tighten the bolt to a torque of 86 Nm

(63 lb-ft). Remove the installation shim.

14. Attach all hoses to the hydraulic pump.

15. Lower the engine and install the front mounting

hardware (15 and 11, Figure 6-4).

16. Remove the lifting chain.

17. Install the alternator and connect the wires to the

alternator and engine bracket.

18. Fill the hydraulic oil reservoir.

NOTE: The hydraulic system requires clean hydraulic oil

for proper operation. Contaminated oil can cause

damage to the pump and other components.

Before adding any hydraulic oil to the hydraulic

system, be sure the oil is filtered through a 10-

micron (absolute) or less filter.

19. Connect the battery cables.

20. Start the engine and let it idle. Check for hydraulic leaks

around the pump. Tighten any loose fittings, clamps, and

hoses if loose.

21. Install the rear tires and raise the outriggers.

22. Tighten the wheel lug nuts to a torque of 408 Nm (300 lb-

ft).

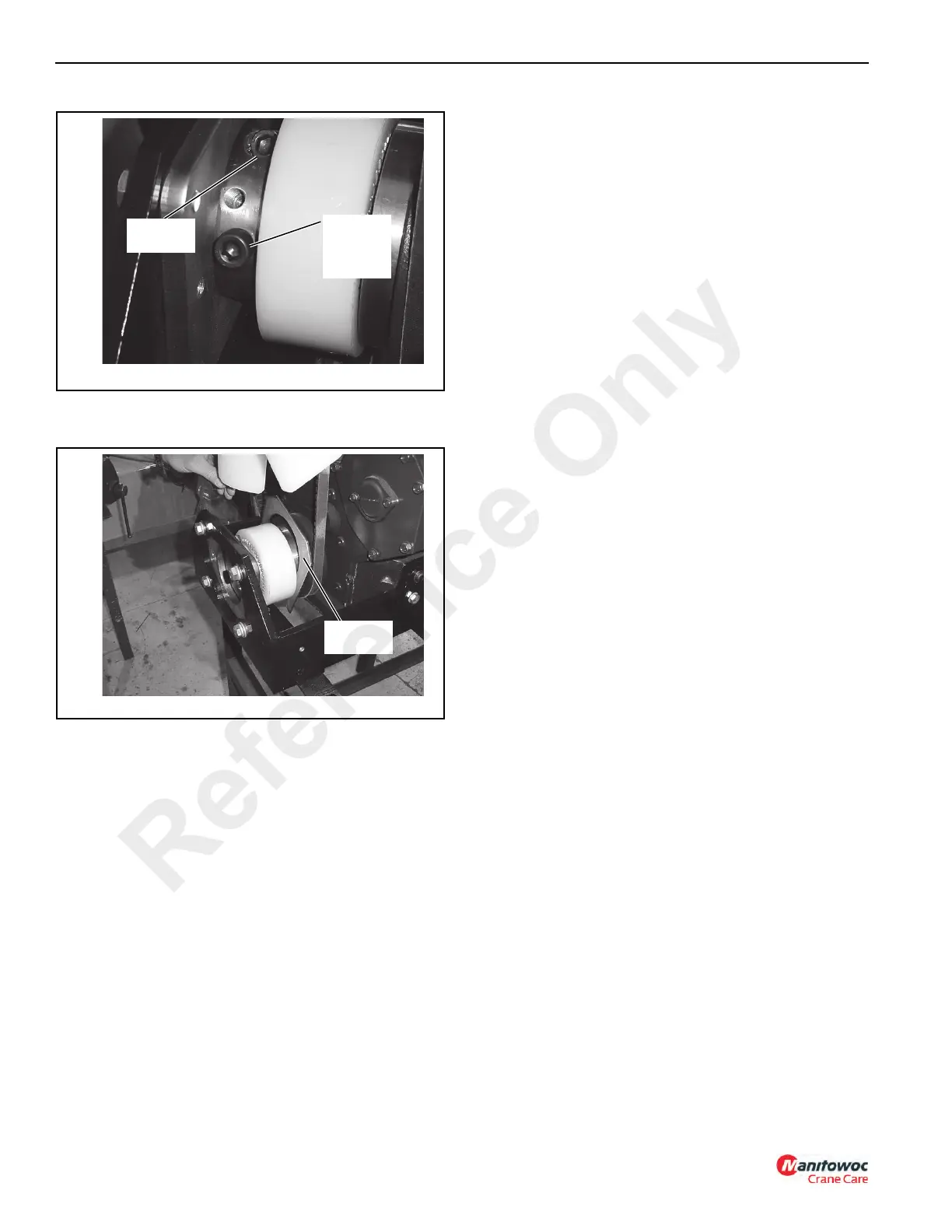

FIGURE 6-13

p1419

Clamping

Bolt

Socket

Head

Capscrew

No. 13

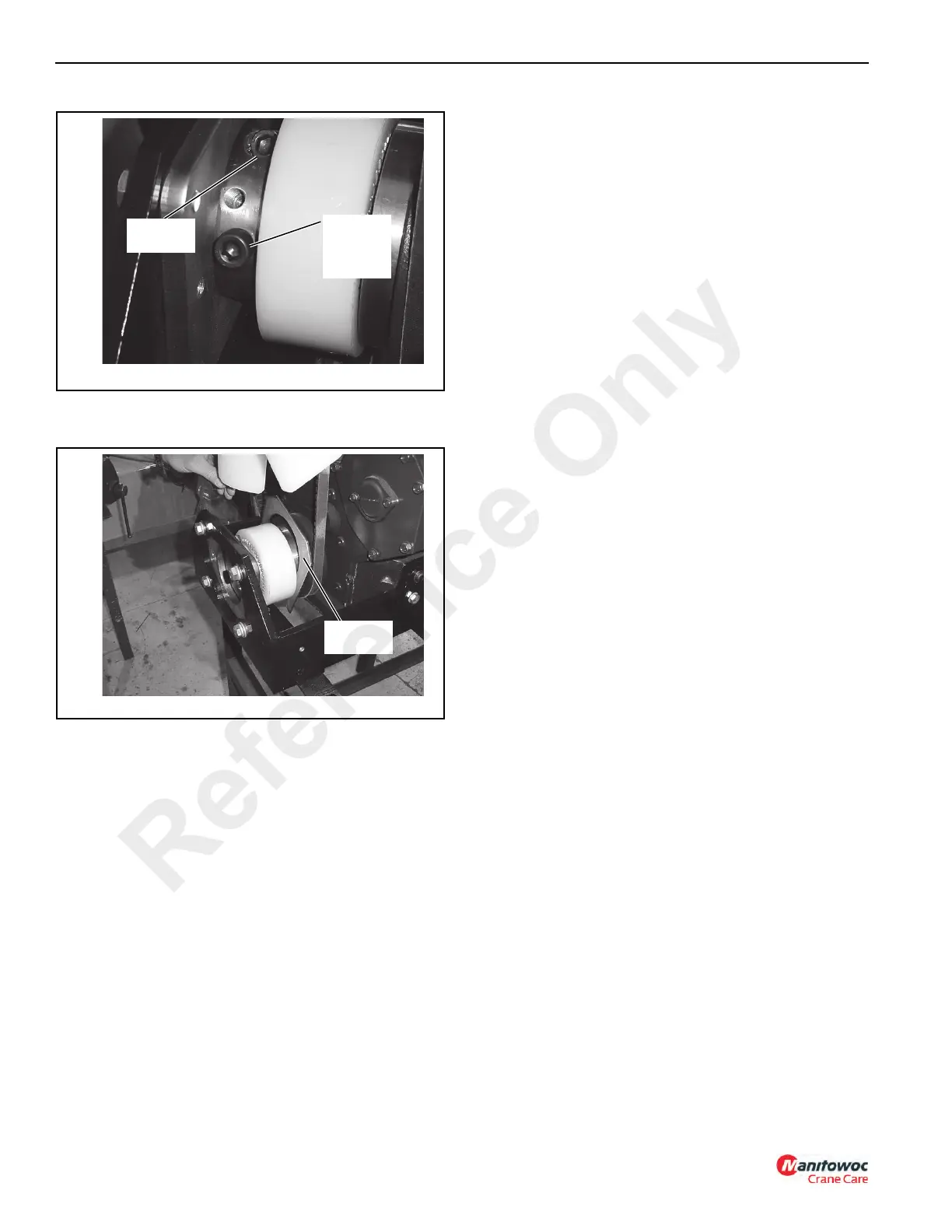

FIGURE 6-14

p1420

Shim

(1007422)

Reference Only

Loading...

Loading...