GROVE 7-47

CD3340B/YB4411 TRANSMISSION AND TORQUE CONVERTER

Published 04/07/2015 Control # 569-00

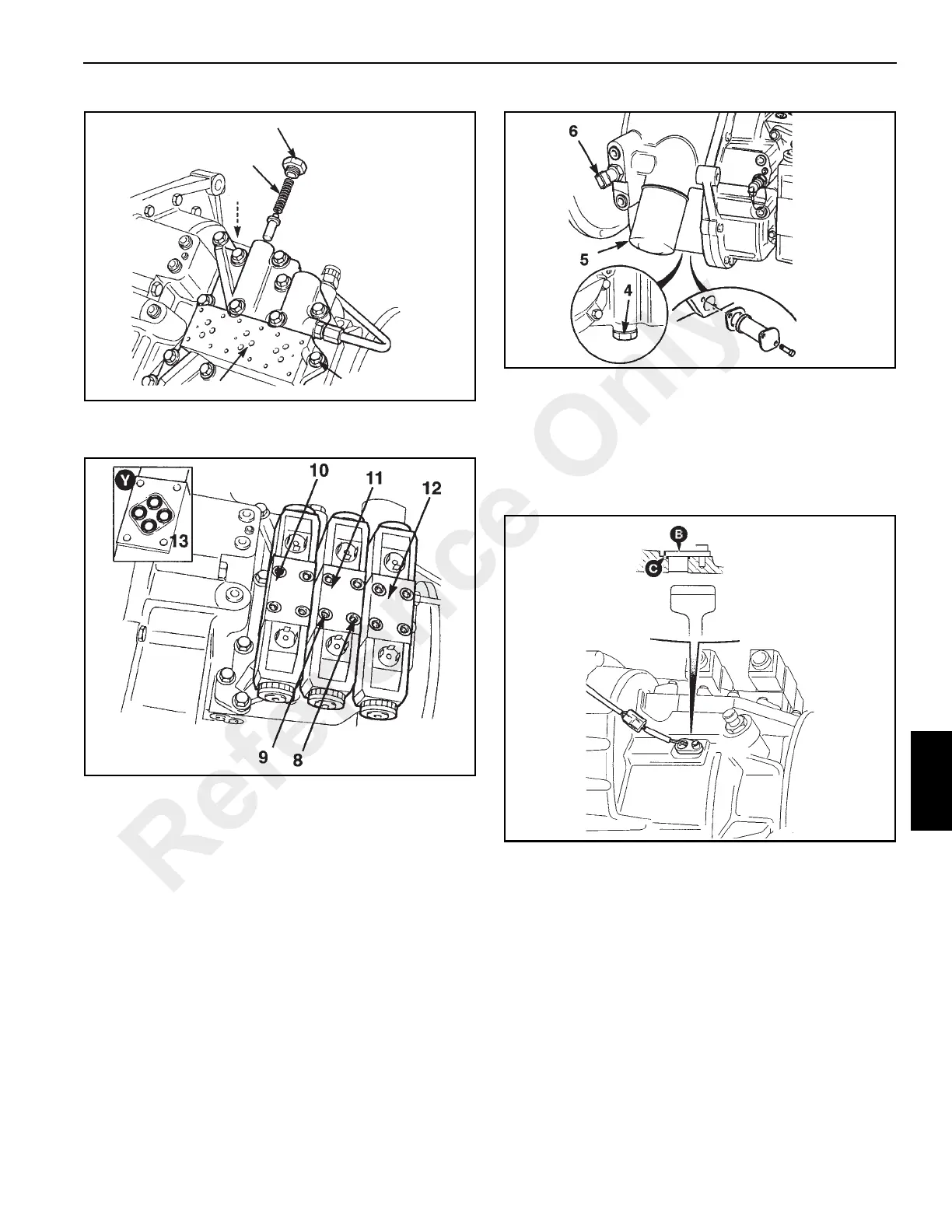

33. Install new O-rings (13, Figure 7-63) into each valve

body.

34. Position the reverse high/low clutch solenoid (12) onto

the adapter block. Install capscrews (9) and tighten to a

torque of 5 Nm (4 lb-ft).

35. Repeat step 34 for the main shaft/layshaft clutch

solenoid (11) and for the forward clutch solenoid (10).

NOTE: The mounting holes will only align when the

solenoid valve has been positioned correctly on the

adapter block.

36. After assembly, insert the plastic caps (8) into the

mounting screw counter-bores to inhibit water and dirt

entry which could inhibit removal at a later date.

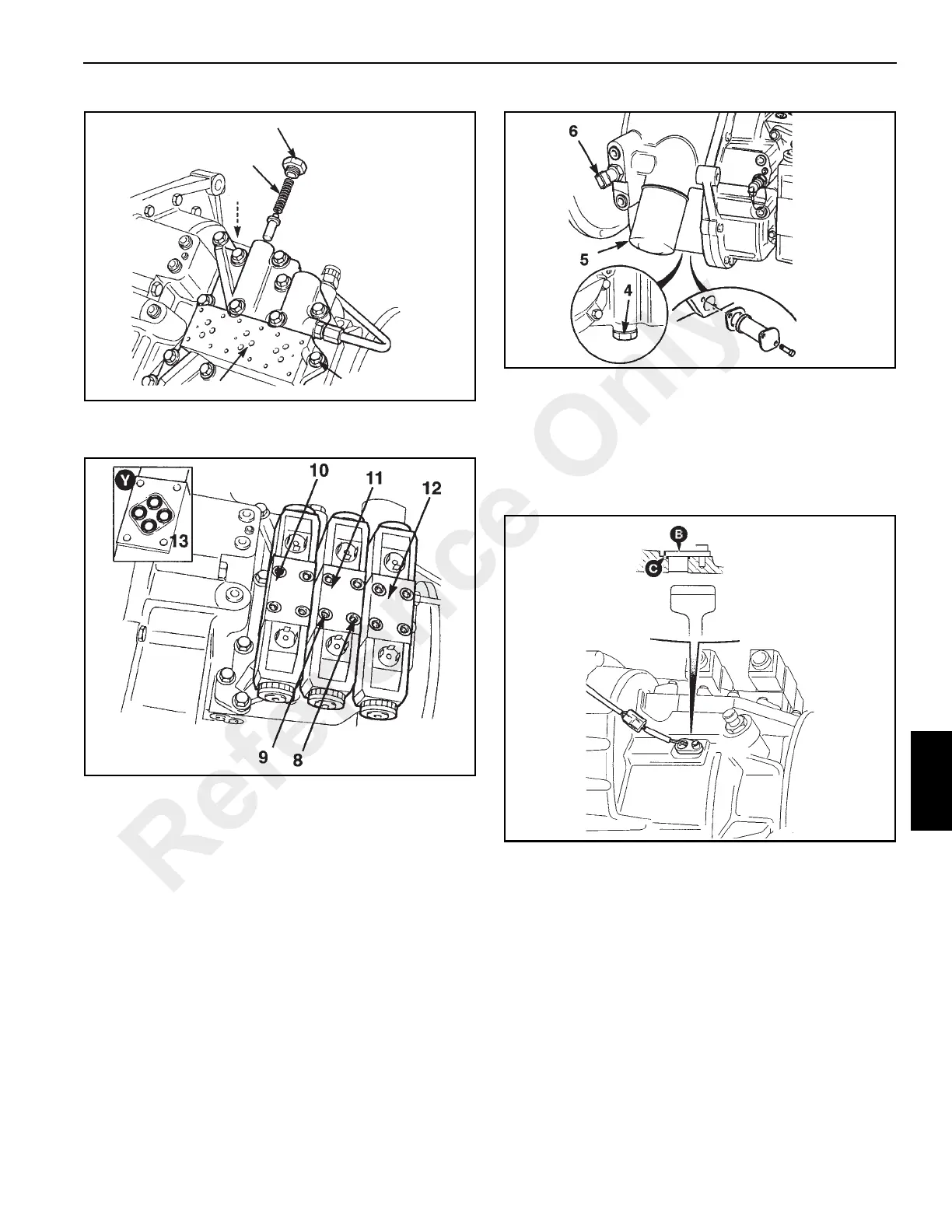

37. Coat the seal of a new filter (5, Figure 7-64) with

transmission oil. Screw the filter on until it just contacts

the filter head. Turn the filter at least another 3/4 turn.

38. Install the drain plug (4) with a new sealing washer.

Tighten to a torque of 203 Nm (150 lb-ft).

39. Install pressure switch (6) with a new sealing washer.

Tighten to a torque of 28 Nm (21 lb-ft).

40. Install the electronic speed sensor (B, Figure 7-65). Use

a new O-ring (C).

Installation

1. Install the torque converter.

2. Clean and lubricate the splines of the transmission input

shaft on the engine.

3. Align the transmission input shaft splines with the

splines of the torque converter impeller and assemble

the transmission/torque converter housing to the engine

flywheel housing. Install the 12 bolts and lockwashers

and tighten to proper torque. See Fasteners and Torque

Values, page 1-8.

4. Install the power unit into the machine. See Engine and

Engine Systems, page 6-1.

FIGURE 7-62

a0807

20

21

18

52

19

Reference Only

Loading...

Loading...