FOCKE MELER GLUING SOLUTIONS INSTALLATION

3-4

Mounting the equipment

For mounting the equipments set the base in the desired location using the

indicated holes M8 screws. To move the equipment more comfortably use the

eyebolts included for this purpose.

Warning: Make sure that the bench where the base plate is fastened is level,

free from vibrations and is able to support the weight of the equipment in

addition to the full tank load.

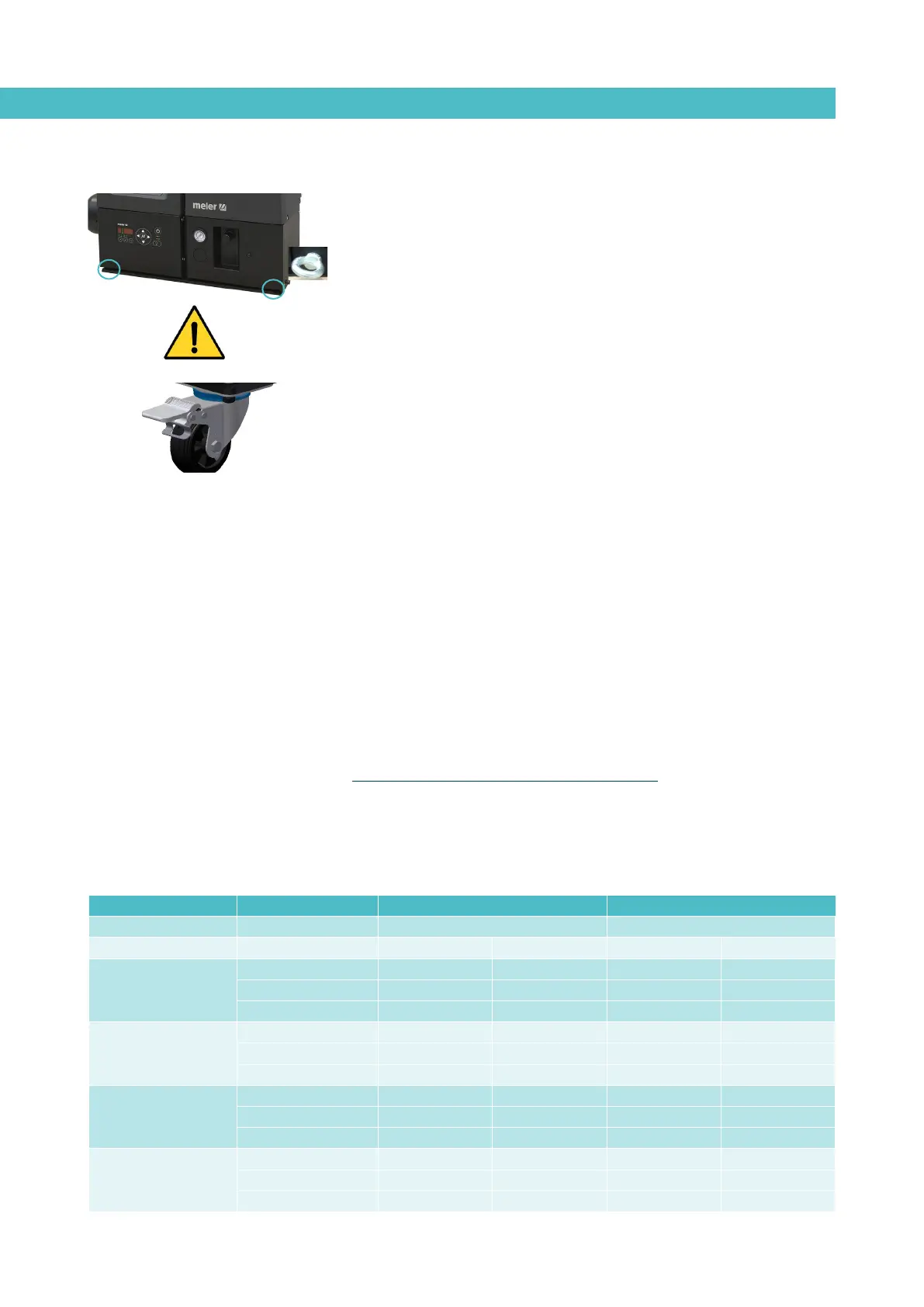

Besides, these melters may come with wheels (optional) so they can be easily

moved and located near to the main machine.

The four wheels turn 360º, and two are equipped with brakes. To move the

unit, unlock the two wheels by lifting the lever.

Slide the unit to its final position. Lock the wheels once again, lowering the

levers.

Electrical power connection

Micron gear series melters are designed to be connected to the electrical

power supply in two possible ways, depending on the power of different

elements connected:

• 1-phase 230 VAC with neutral.

• 3-phases 230 VAC without neutral.

• 3-phases 400 VAC with neutral.

A good ground connection is required in all cases.

Consumption figures, according to melter and output configuration, are

included in the table. For this calculation, only the case of a single pump has

been taken into account. For consumption with a double pump, please check

with us. Due to high power connected Meler recommends 3-phases 400 VAC

with neutral connection.

Equipment No. Outputs 1 Phase 3 Phases + N

230 VAC 400 VAC Y

1 PUMP 2 PUMPS 1 PUMP 2 PUMPS

Micron 5

2 25.17 A 31.00 A 12.87 A 16.70 A

4 35.60 A 41.42 A 12.87 A 21.91 A

6 46.04 A - 12.87 A -

Micron 10

2 29.52 A 35.34 A 17.23 A 16.70 A

4 39.95 A 45.77 A 17.23 A 21.91 A

6 50.39 A - 17.28 A -

Micron 20

2 27.39 A 37.51 A 19.41 A 16.70 A

4 42.13 A 47.95 A 19.41 A 21.91 A

6 52.56 A - 19.41 A -

Micron 35

2 38.21 A 44.03 A 16.30 A 16.70 A

4 48.65 A 54.47 A 21.52 A 21.91 A

6 59.08 A - 26.74 A -

Loading...

Loading...