MELTER OPERATION

4-7

MA-5079-ENG MICRON GEAR ADHESIVE MELTER

Standby function does not generate any alarm.

If a temperature sensor is broken, the system heats all the elements except

the one where the failure is located.

In case of overheating the system cuts off inmediately the damaged element.

After three minutes if the failure continues all the system will be shut down.

After repairing the failure the system starts heating normally.

Hot-melt level display (optional)

If the equipment is fitted with a level detector, and the hot-melt level drops

below the programmed level (capacitive detector) or 1/3 of the tank capacity

(float type detector), a signal is sent to the melter control which launches the

following actions:

1. On-screen display (if this function is activated).

2. Closure of one voltage-free output contact. The user will install the

required device (acoustic warning device, lamp or PLC input).

Simply refill the tank and wait until the adhesive is sufficiently melted for the

detector to provide a reading of the correct level.

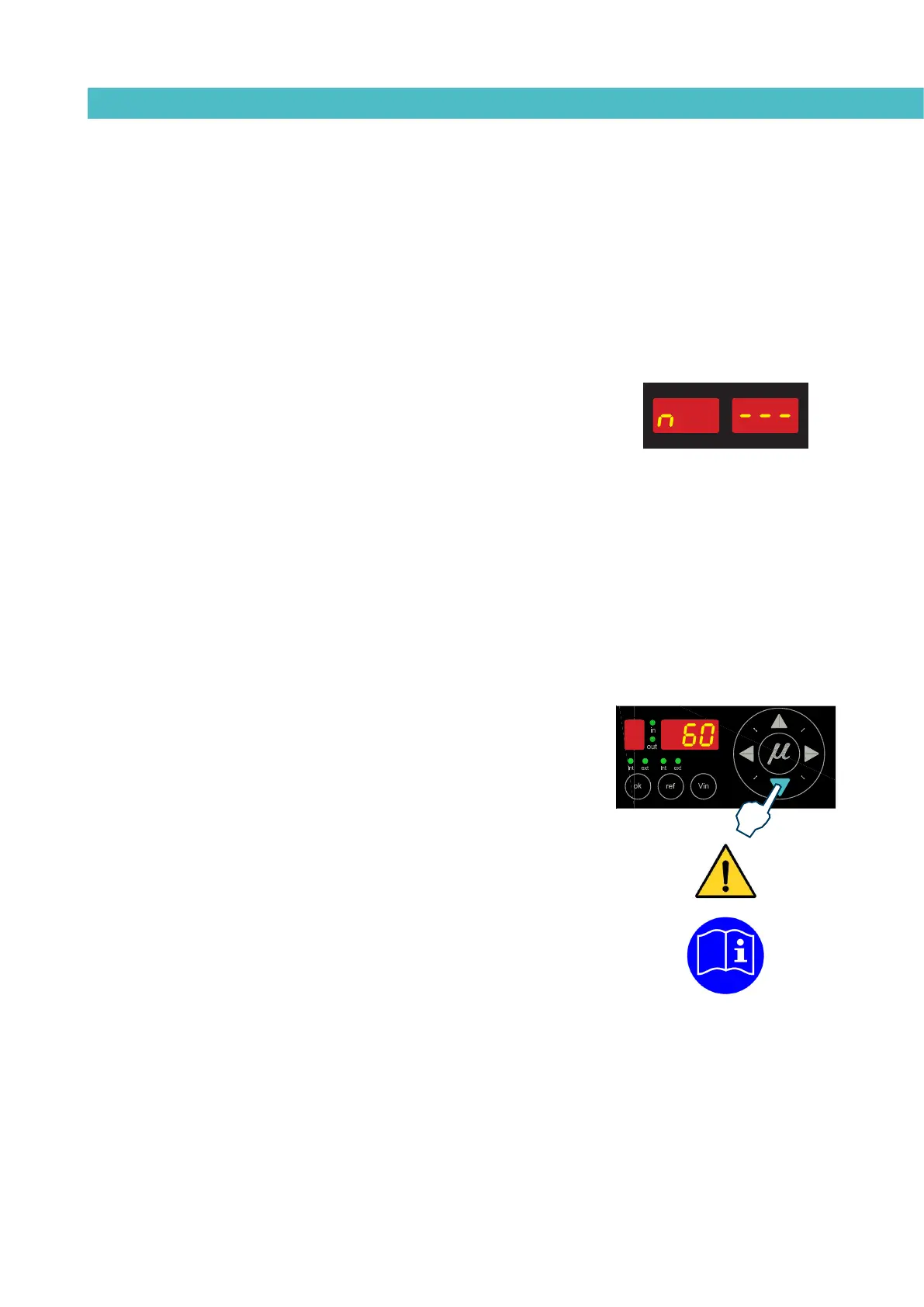

Display and adjustment of the working speed

The pump rotation speed (in revolutions per minute) is shown on the

display for each pump control card on the equipment. These revolutions

may be adjusted by using the up/down arrow keys (pumping speed, internal

reference), through a voltage signal from the main machine or by modifying

the full scale (pumping speed, external reference). The pump rotation speed

must be adjusted to the requirements of the application.

Warning: Although rotation speeds can be selected between 0 and 100 rpm

it is not advisable to operate at speeds of less than 10 rpm (the flow may

become inconstant depending on the motor load) or greater than 80 rpm

(pump operating at maximum revolutions).

Note: for further information on adjusting working speeds, see the section

‘Modes of operation’.

Loading...

Loading...